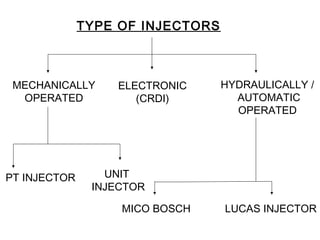

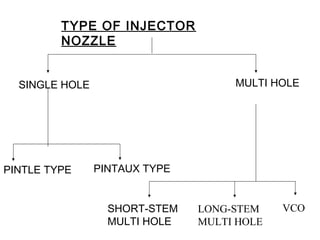

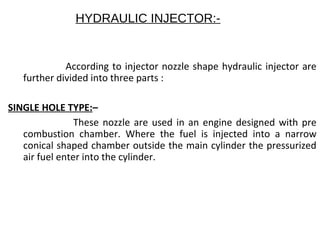

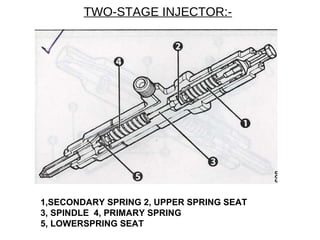

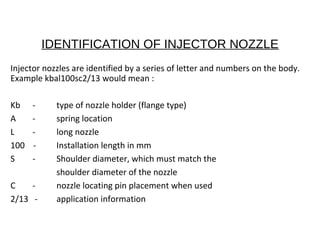

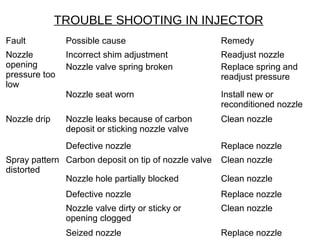

The document discusses the function and types of fuel injectors, detailing their components and operations for optimal fuel atomization and distribution. It highlights various injector types, including mechanical, electronic, and two-stage injectors, along with the specific designs of nozzles used for different engine requirements. Additionally, it addresses testing procedures for injectors and trouble-shooting methods for common issues encountered with fuel injectors.