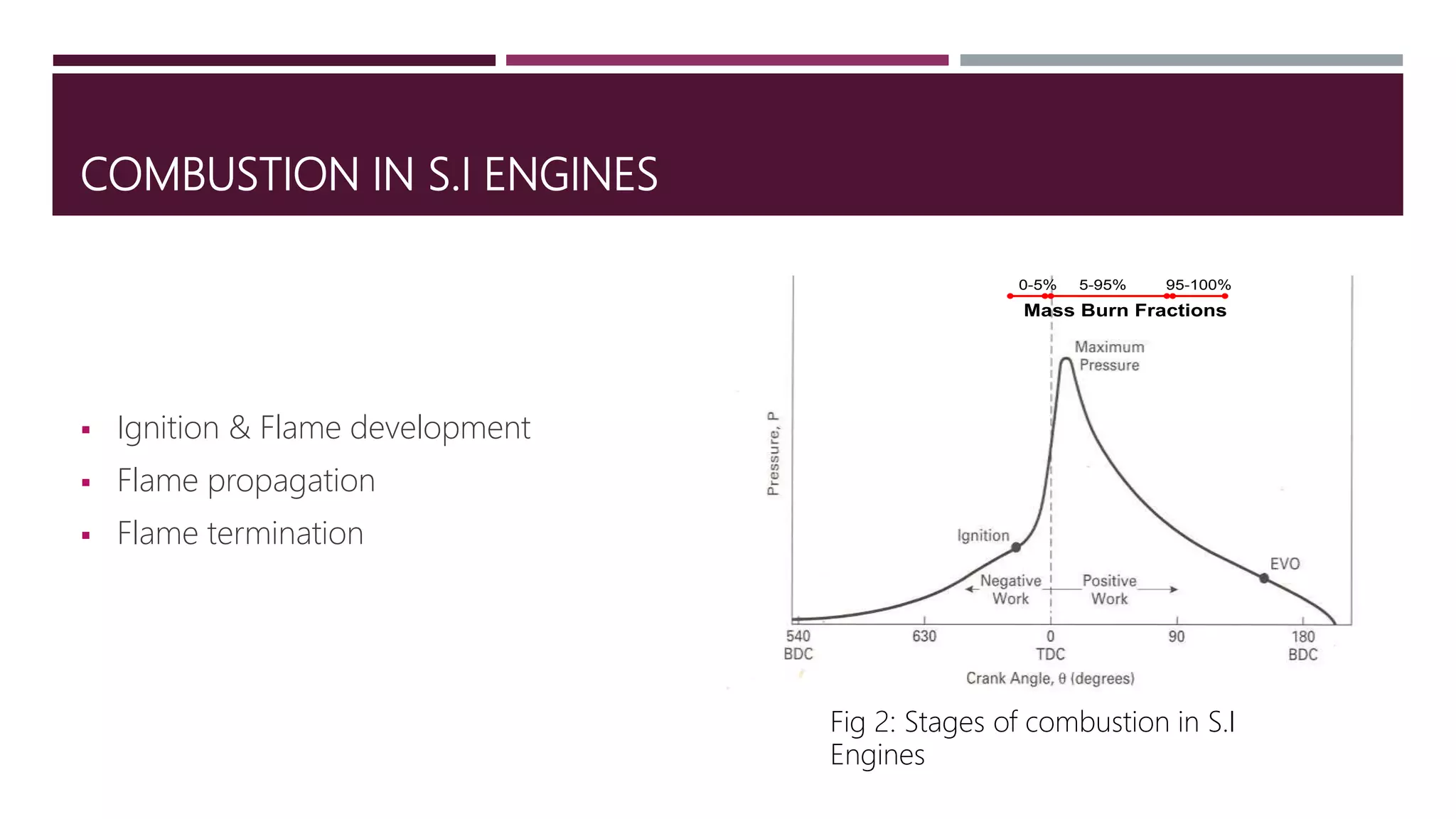

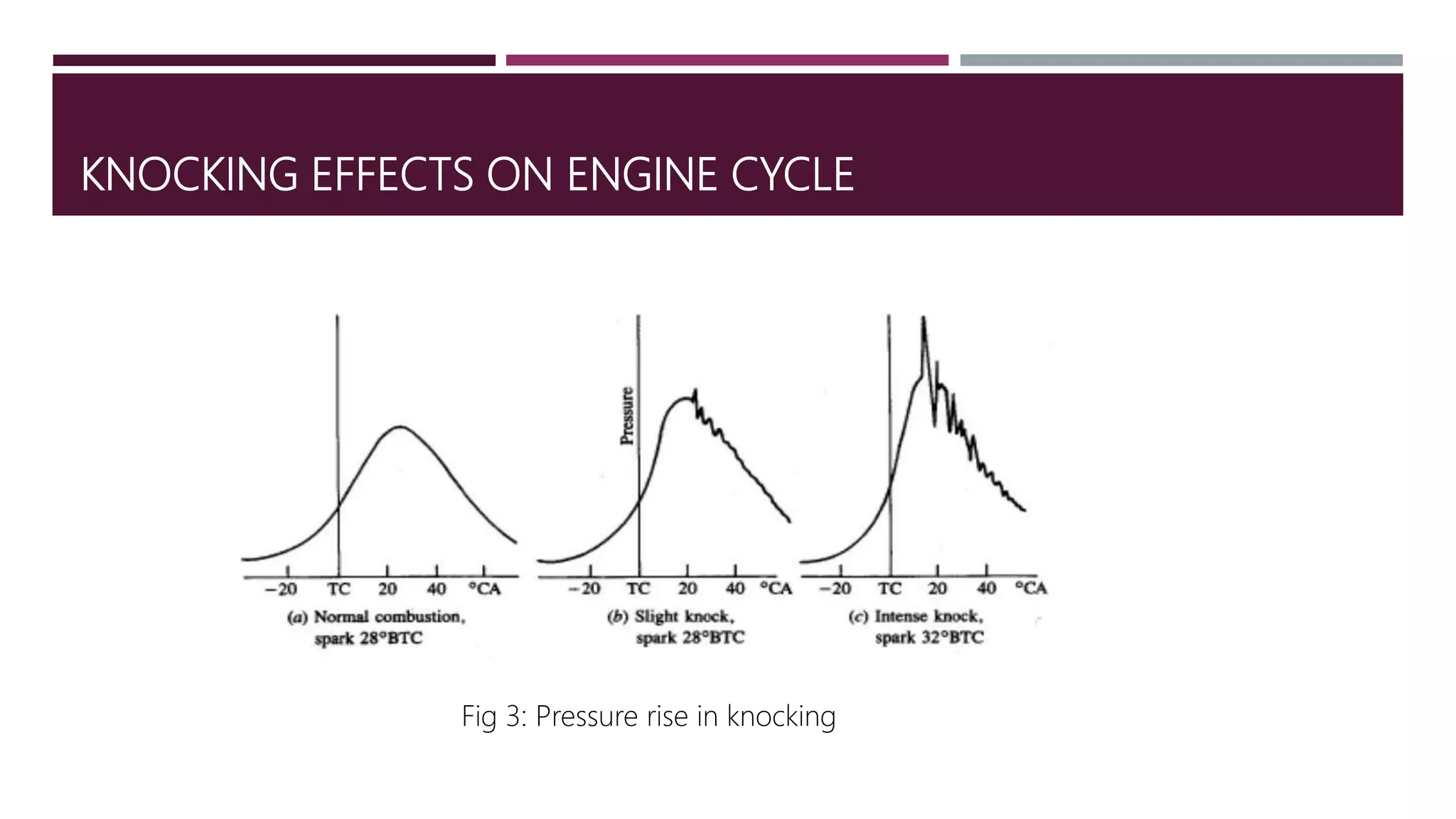

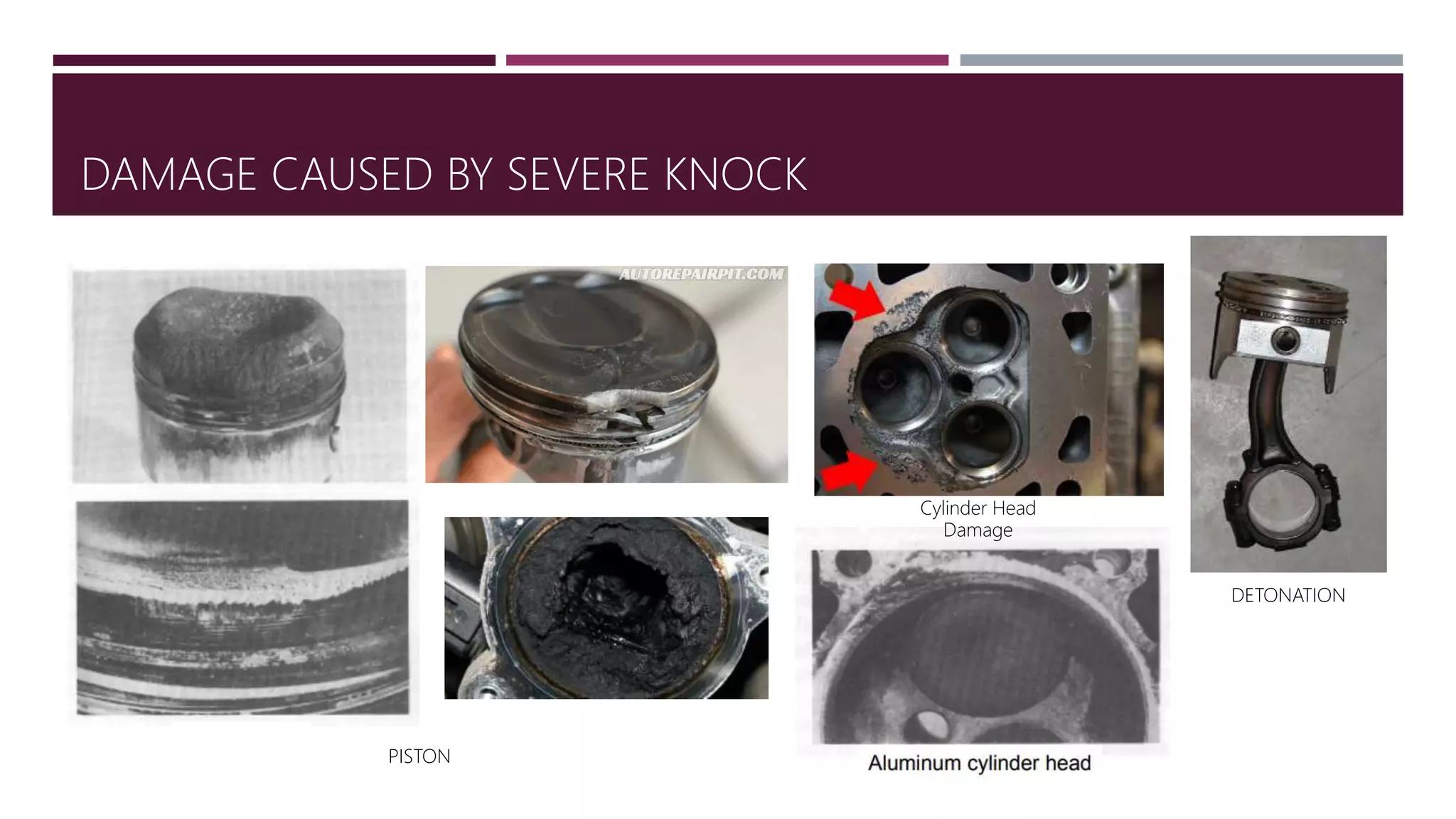

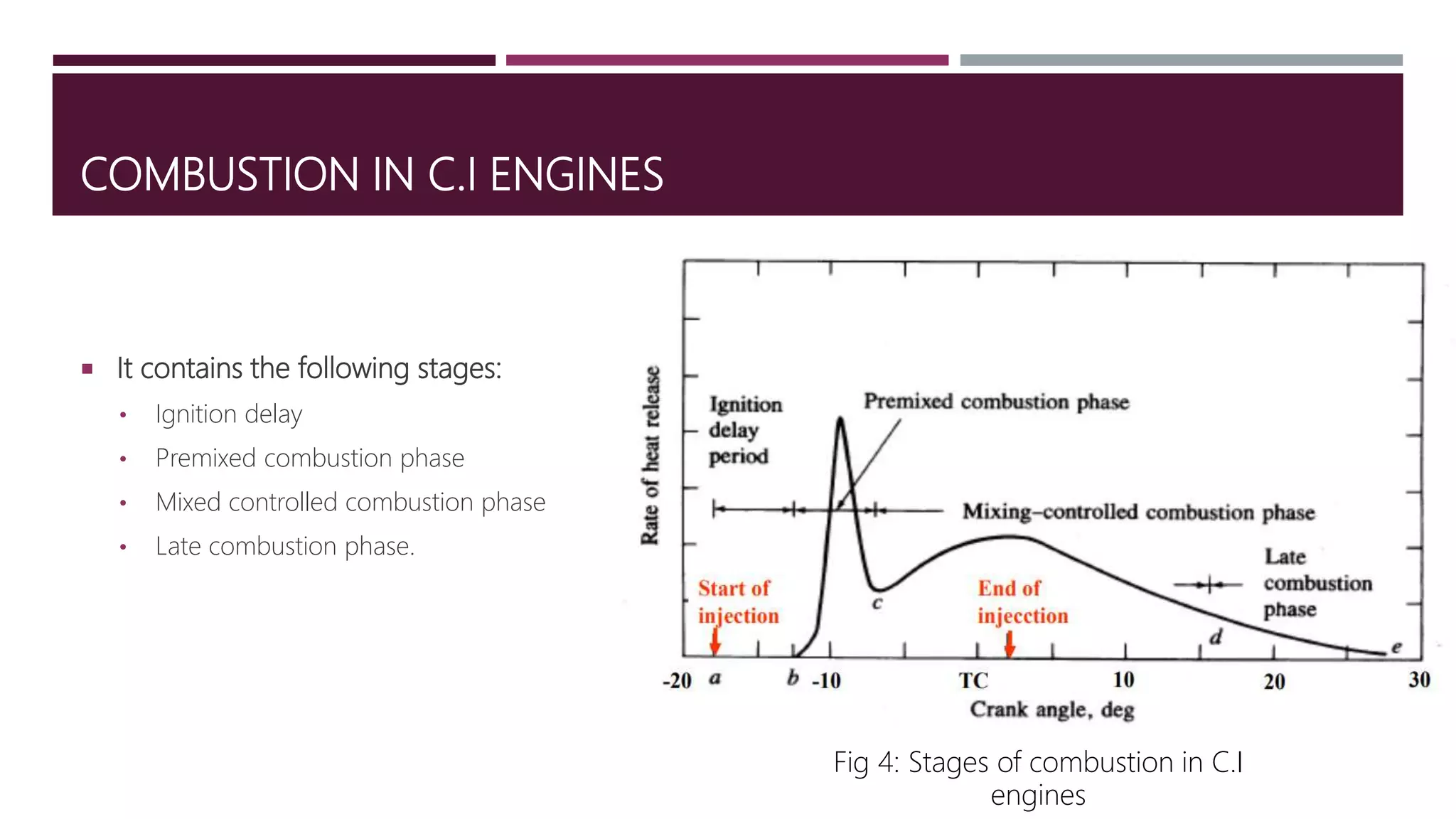

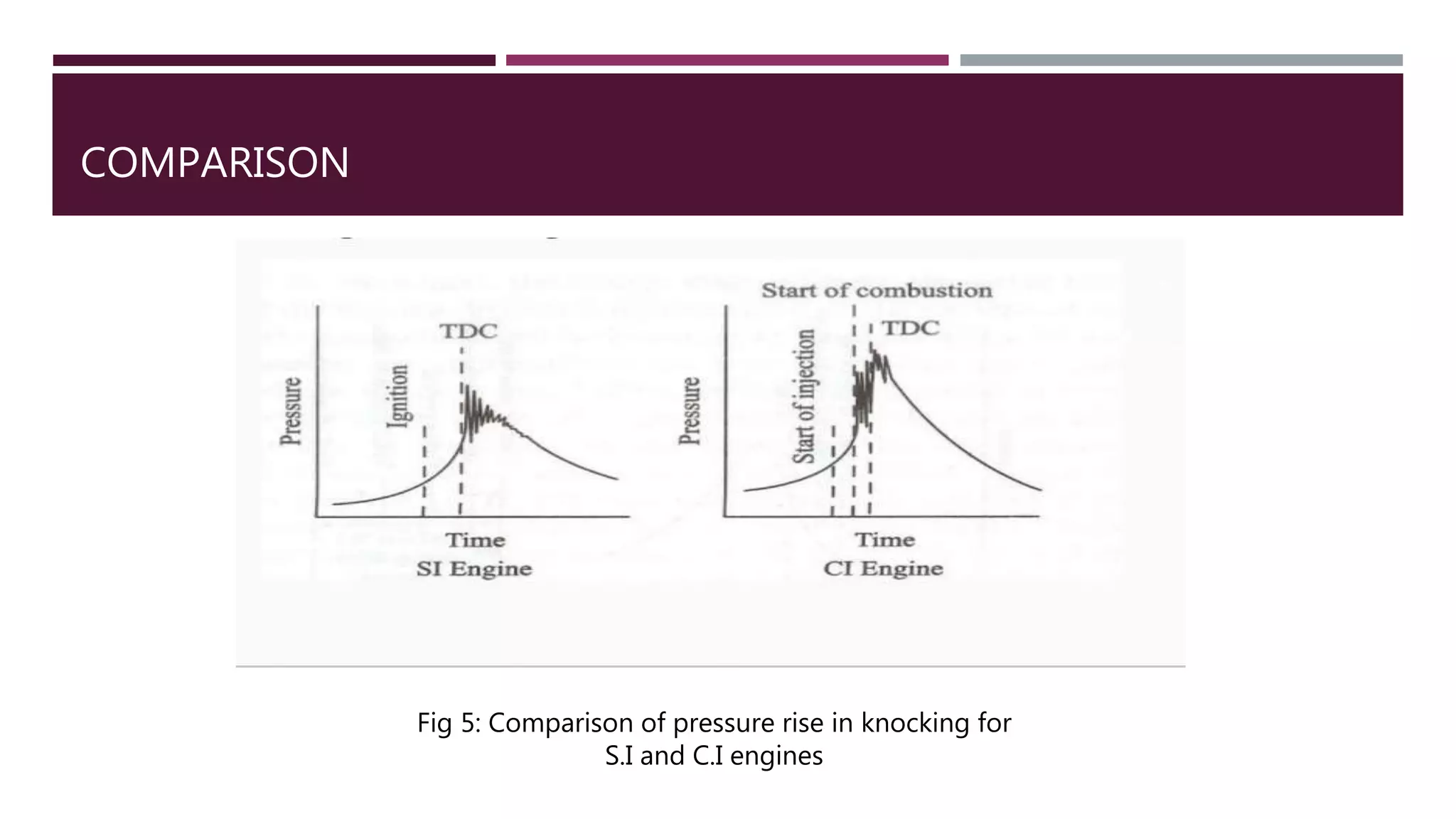

The document discusses the combustion process in internal combustion engines, detailing types such as normal and abnormal combustion, and their effects on engine performance, efficiency, and emissions. It highlights factors influencing combustion in spark ignition (SI) engines and common issues like knocking, providing methods for controlling these problems. Additionally, the document compares combustion stages and challenges in both spark ignition and compression ignition engines.