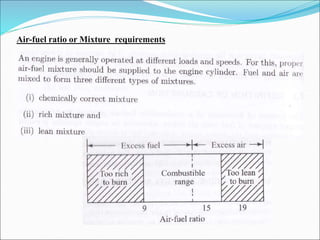

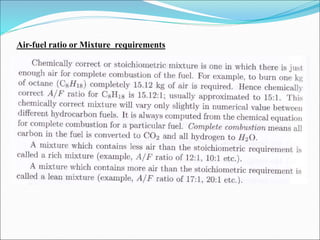

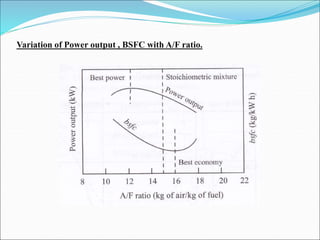

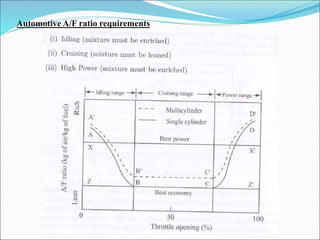

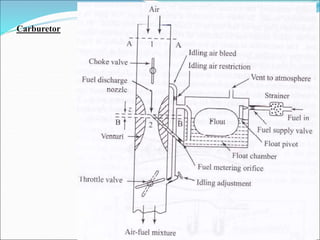

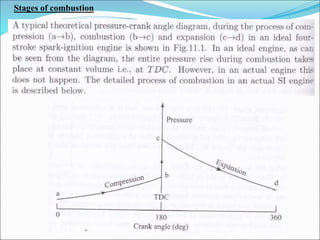

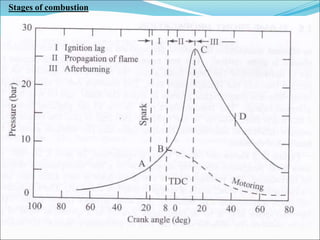

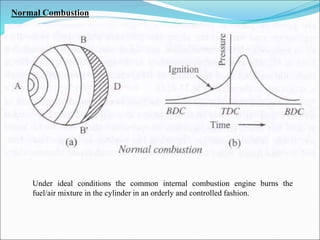

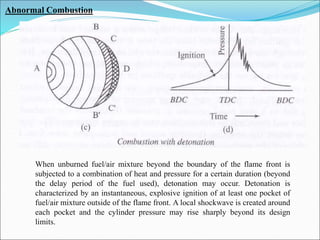

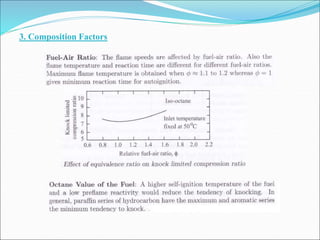

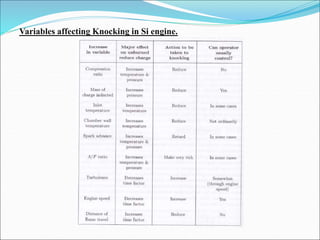

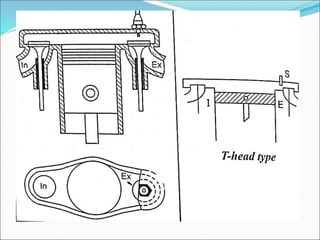

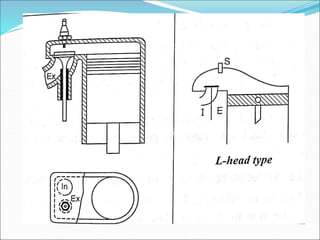

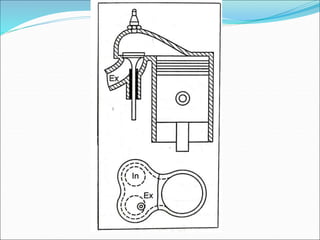

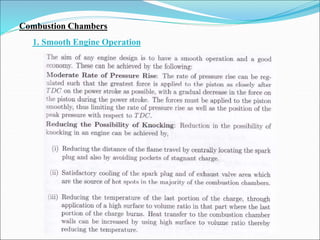

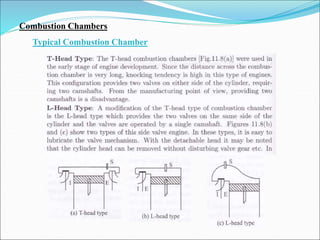

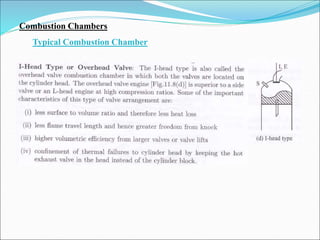

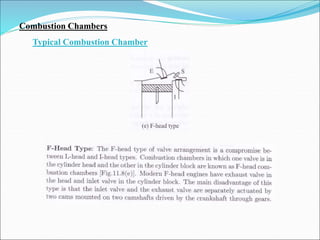

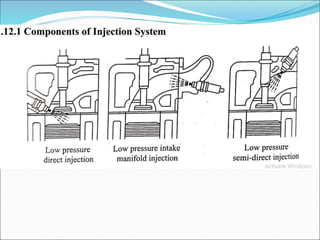

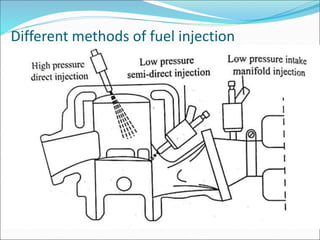

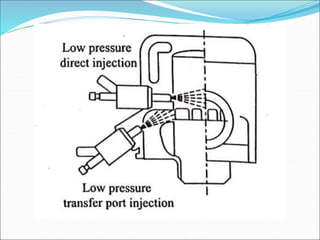

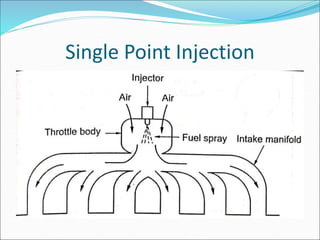

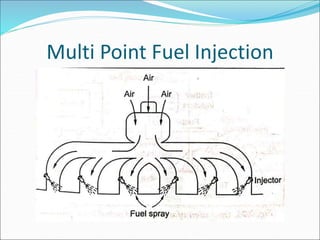

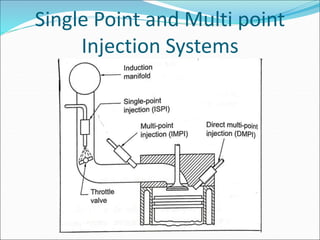

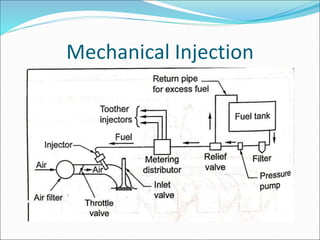

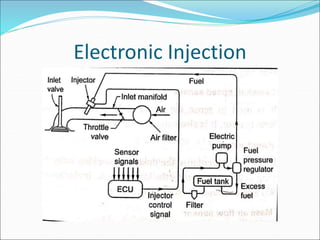

This document discusses spark ignition engines and various aspects of their combustion process. It covers topics like air-fuel ratio requirements, the stages of combustion including normal and abnormal combustion. It describes factors that affect knocking, different fuel injection systems, and combustion chamber designs. It also discusses variables that influence knocking in spark ignition engines.