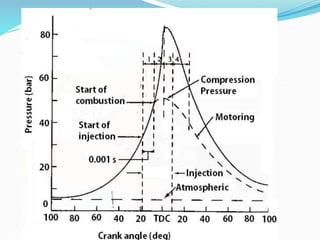

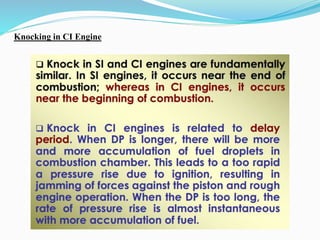

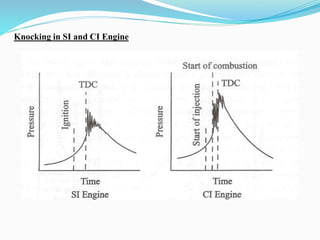

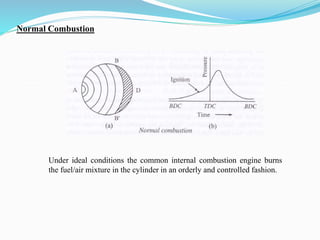

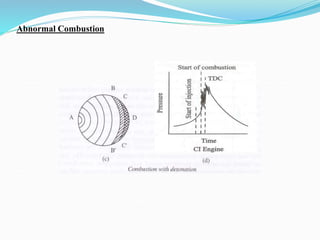

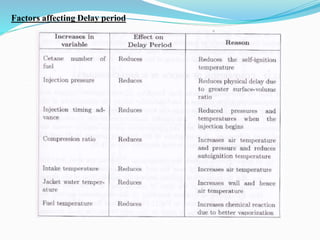

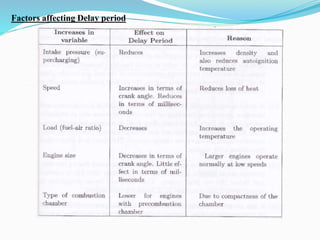

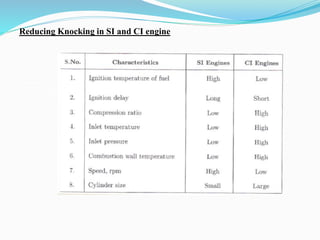

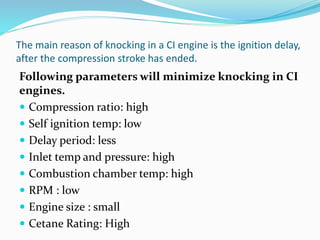

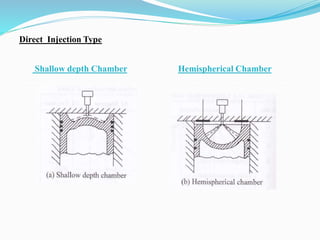

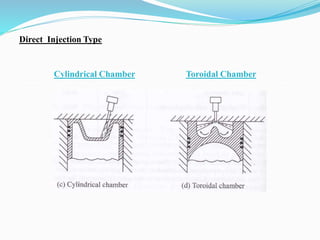

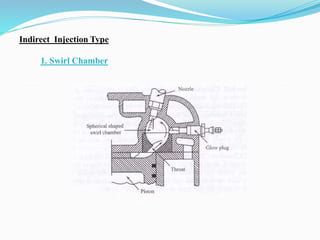

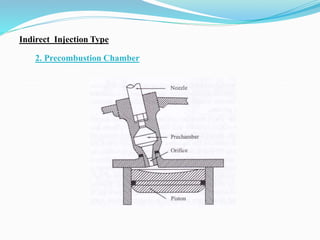

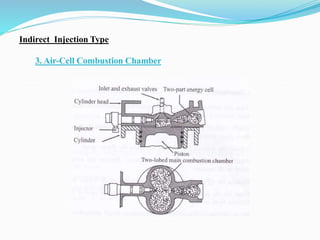

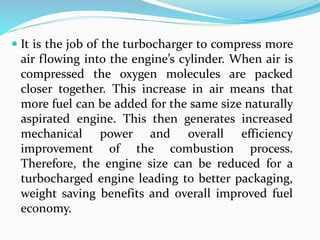

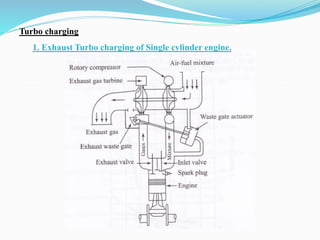

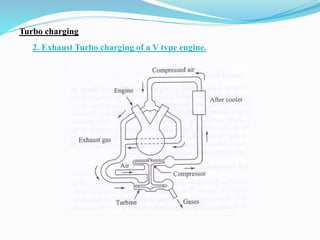

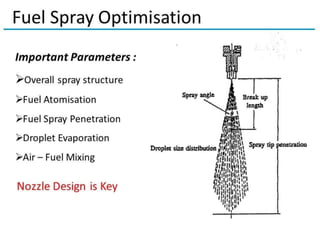

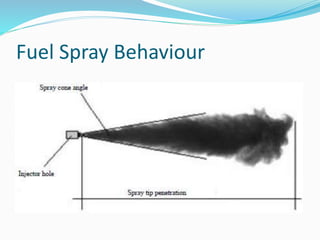

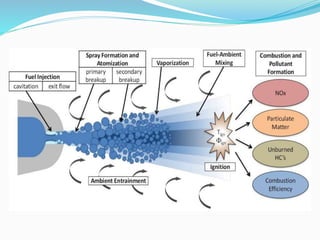

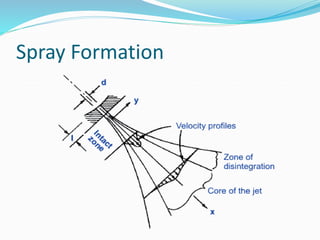

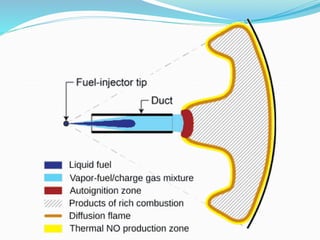

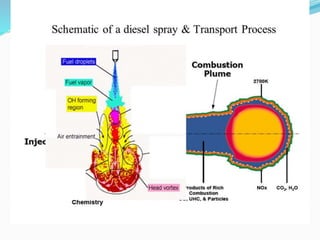

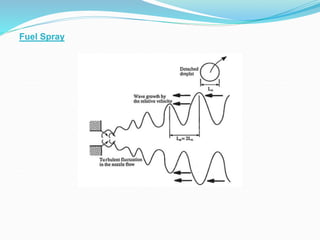

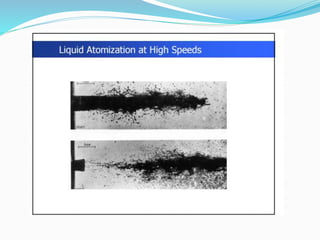

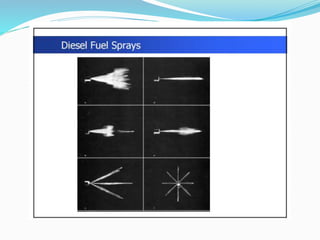

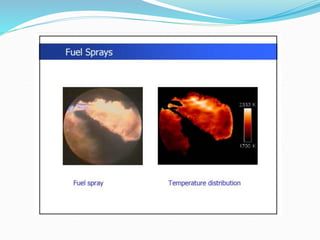

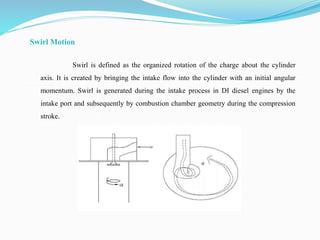

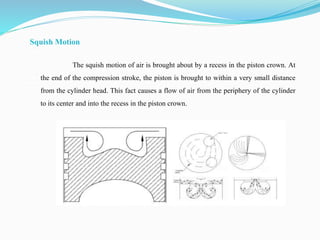

The document discusses diesel fuel injection systems and combustion in compression ignition engines. It covers the stages of combustion (ignition lag, rapid combustion, controlled combustion, after burning), factors that affect ignition delay and knocking, different combustion chamber designs (direct injection, indirect injection), fuel spray behavior, and the role of air motion within the cylinder. Turbocharging is introduced as a way to compress more air into the cylinder before fuel injection, enabling increased power output and efficiency.