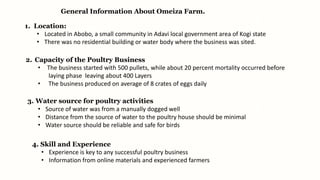

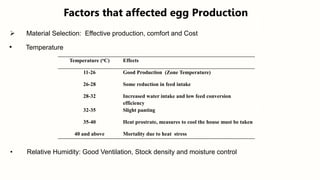

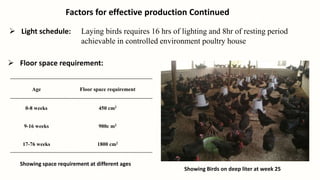

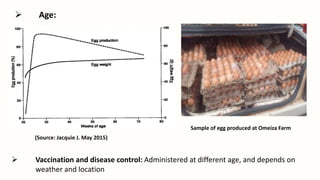

This document summarizes a case study of Omeiza Farm, a small-scale poultry egg production business in Nigeria. The farm started with 500 pullets and specialized in egg production using a deep litter system. Key aspects summarized include the rationale for starting the business, general farm information including location and capacity, housing requirements, factors that affected egg production such as temperature and lighting, challenges encountered, and recommendations to improve small-scale poultry production.