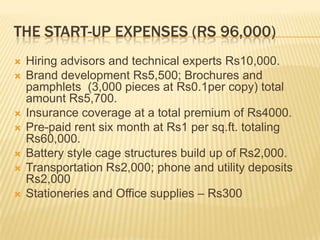

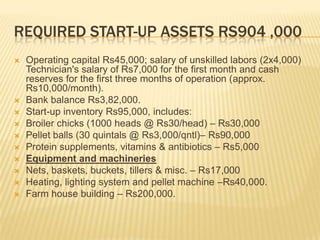

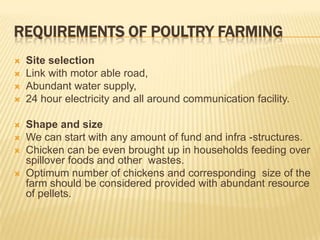

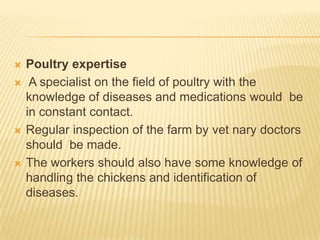

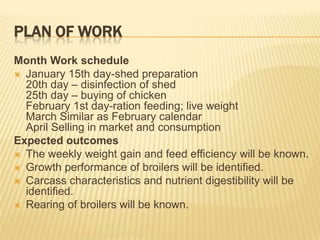

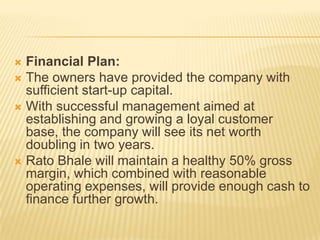

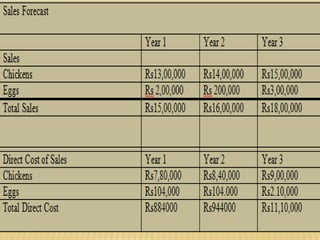

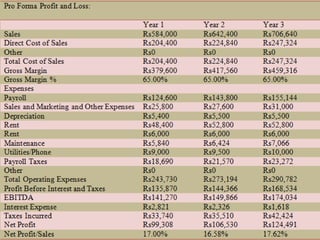

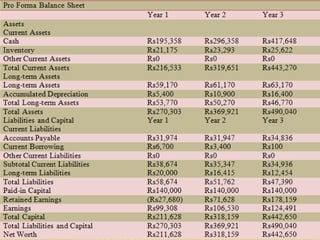

The document outlines plans to start a poultry farm business called Rato Bhale Poultry Producer in Nepal. The owners have conducted research showing potential for growth in Nepal's poultry market. They plan to establish a farm with 1000 chickens and sell meat to reduce the country's reliance on imports. The summary provides details on the farm location, investments, operations, expected profits, and goals to become a leading local producer.