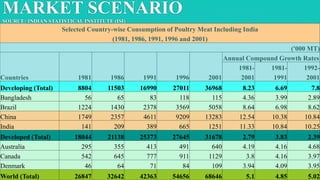

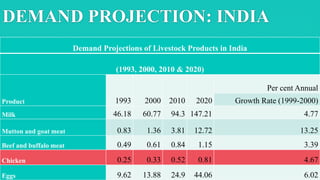

- Worldwide consumption of poultry is increasing, with India emerging as the 2nd largest market growing at over 14% annually. However, per capita consumption in India remains well below recommended levels.

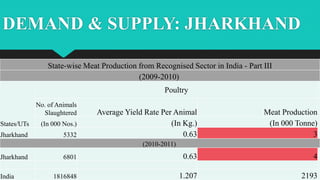

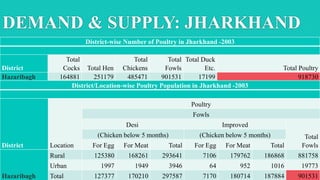

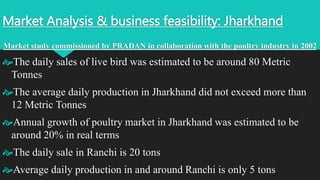

- The poultry industry in Jharkhand is growing at 20% annually but local production meets only a fraction of daily demand. A market study identified potential for expansion.

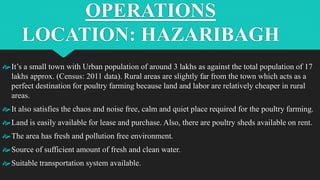

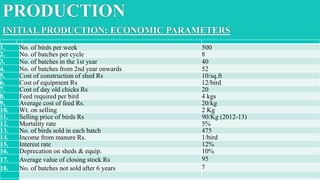

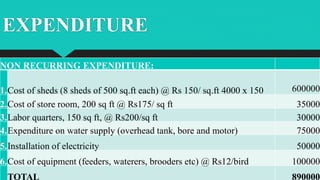

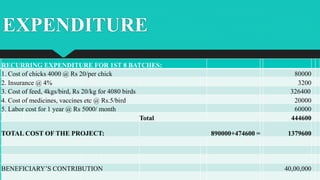

- A proposed commercial poultry farm in Hazaribagh, Jharkhand was estimated to generate a net profit within 6 years, through rearing broiler chickens in batches of 500 birds each week for meat production. Infrastructure, equipment, feed and operating costs were calculated.

- While demand exceeds supply locally, opportunities exist