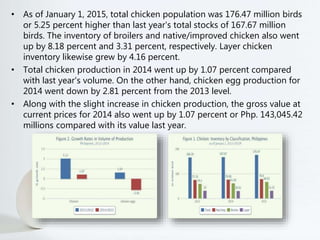

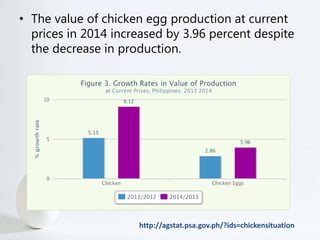

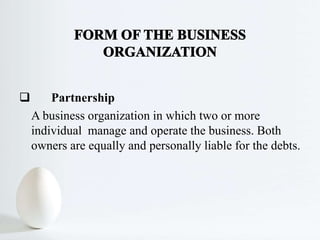

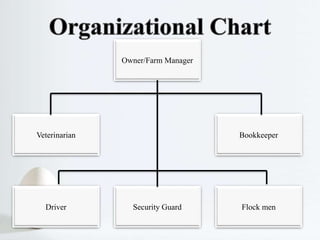

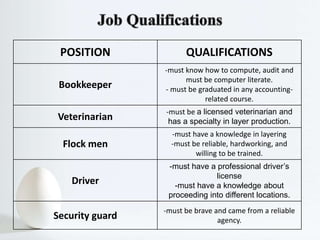

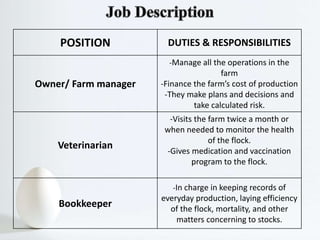

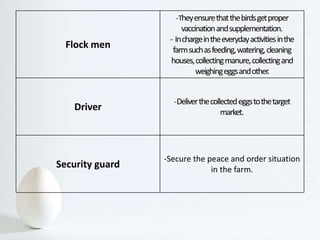

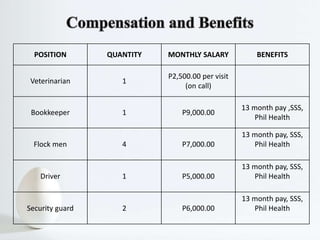

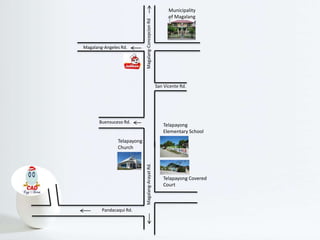

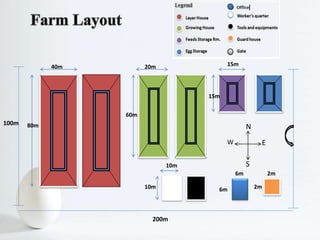

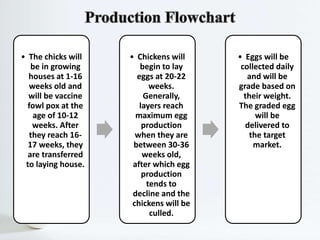

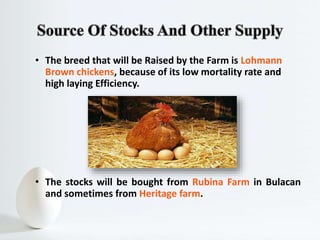

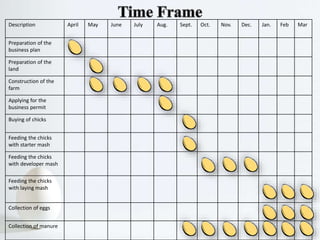

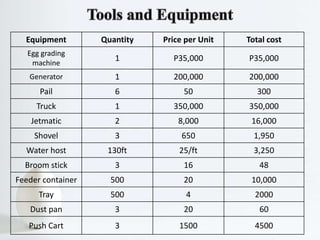

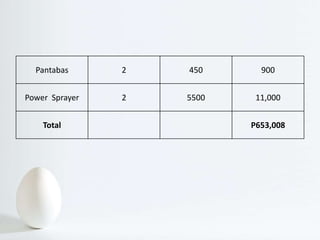

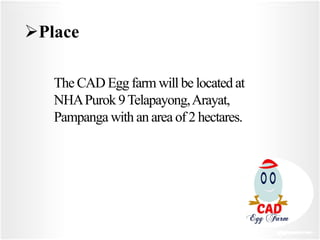

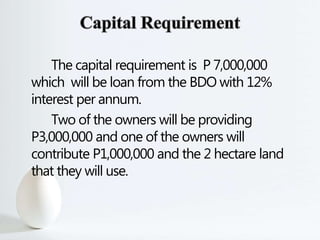

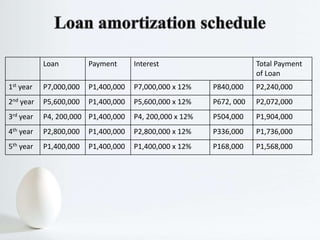

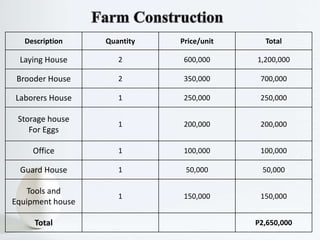

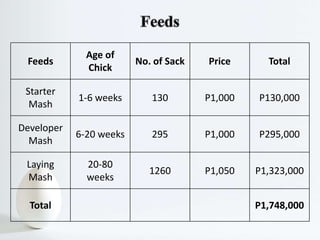

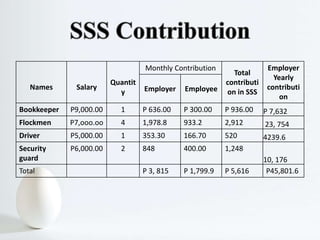

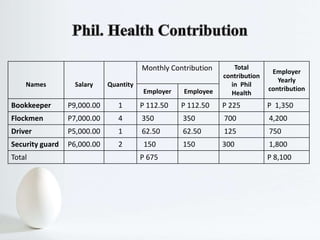

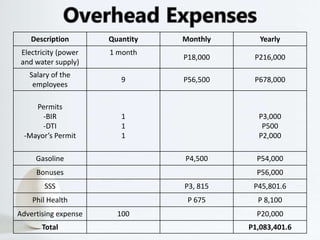

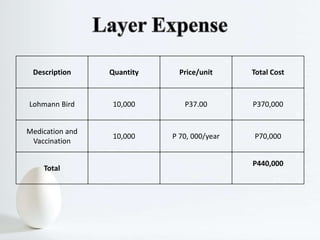

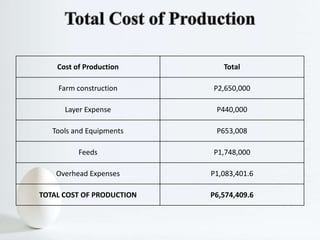

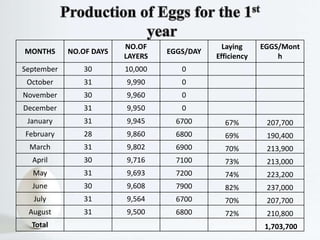

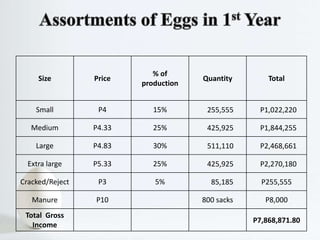

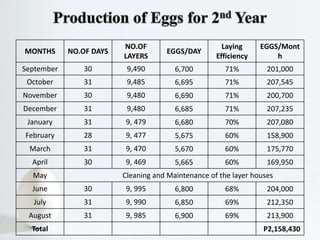

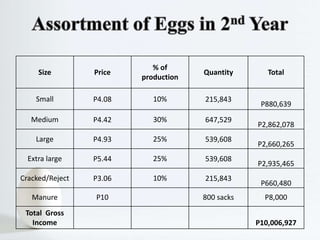

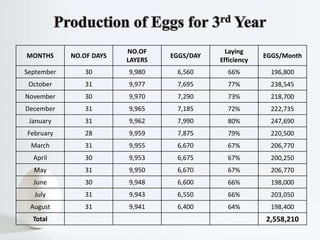

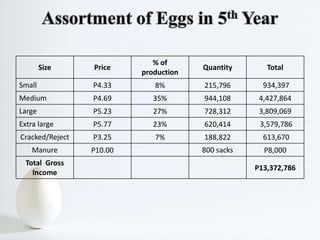

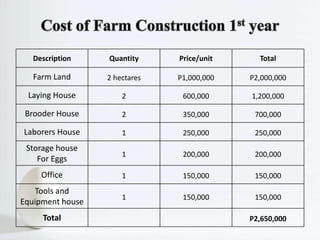

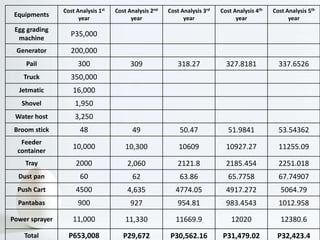

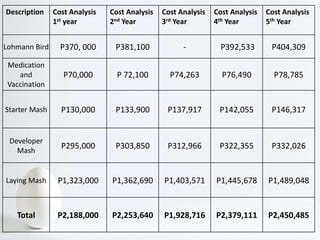

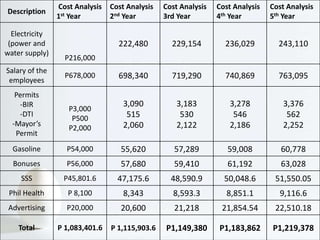

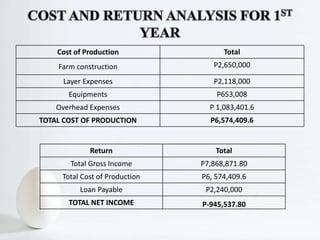

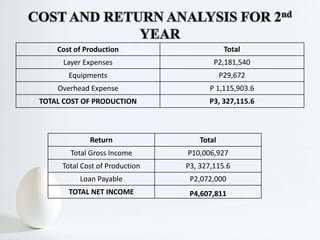

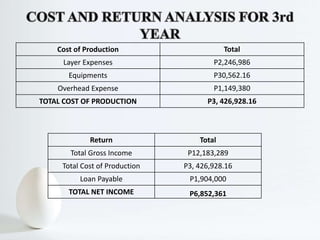

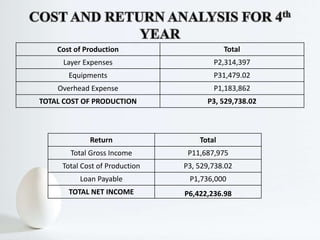

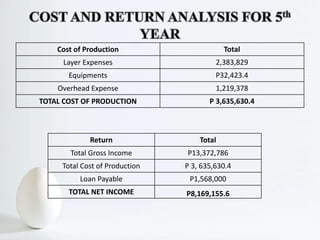

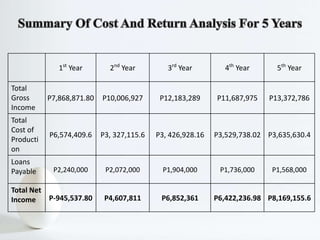

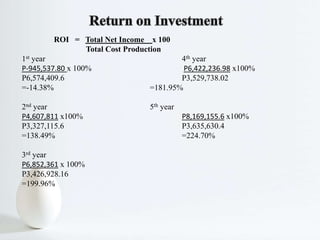

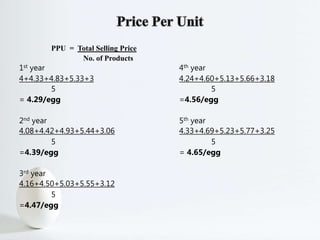

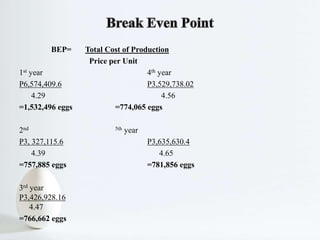

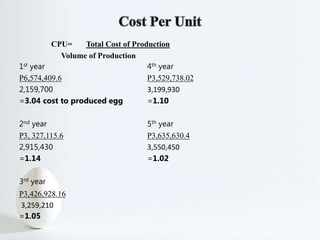

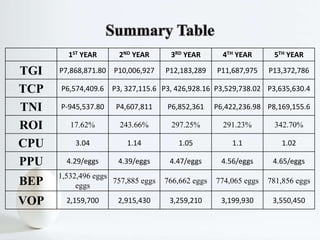

The document is a business proposal for a poultry farm focusing on chicken broiler and egg production in the Philippines, outlining an organization and management plan, production strategies, and financial projections. It highlights the growth of the poultry industry, the operational roles of employees, and a detailed budget for startup costs and salary. The proposal also includes market analysis, production goals, and an assessment of the poultry breeds to be utilized.