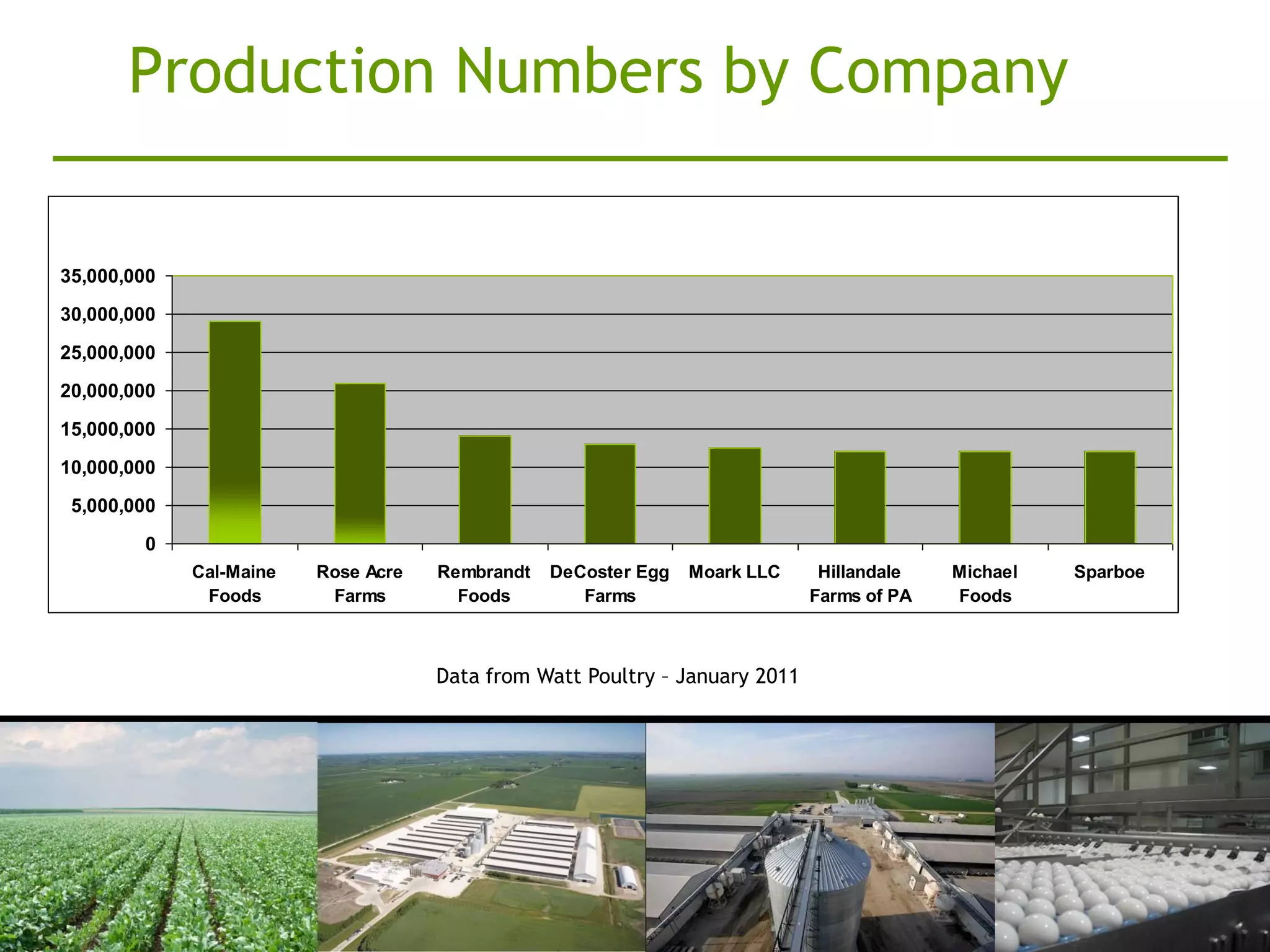

Rembrandt Foods has grown to become one of the largest egg producers and processors in the world through strategic vertical integration and acquisitions since 2000. It owns 14 million egg-laying hens and focuses exclusively on egg products rather than shell eggs. The company aims to be the lowest cost and most sustainable producer through efficient operations, waste reduction initiatives, and by producing more food using fewer resources. Rembrandt offers a wide range of egg products for foodservice and manufacturing customers across liquid, frozen, dried, and pre-cooked categories to meet various needs.