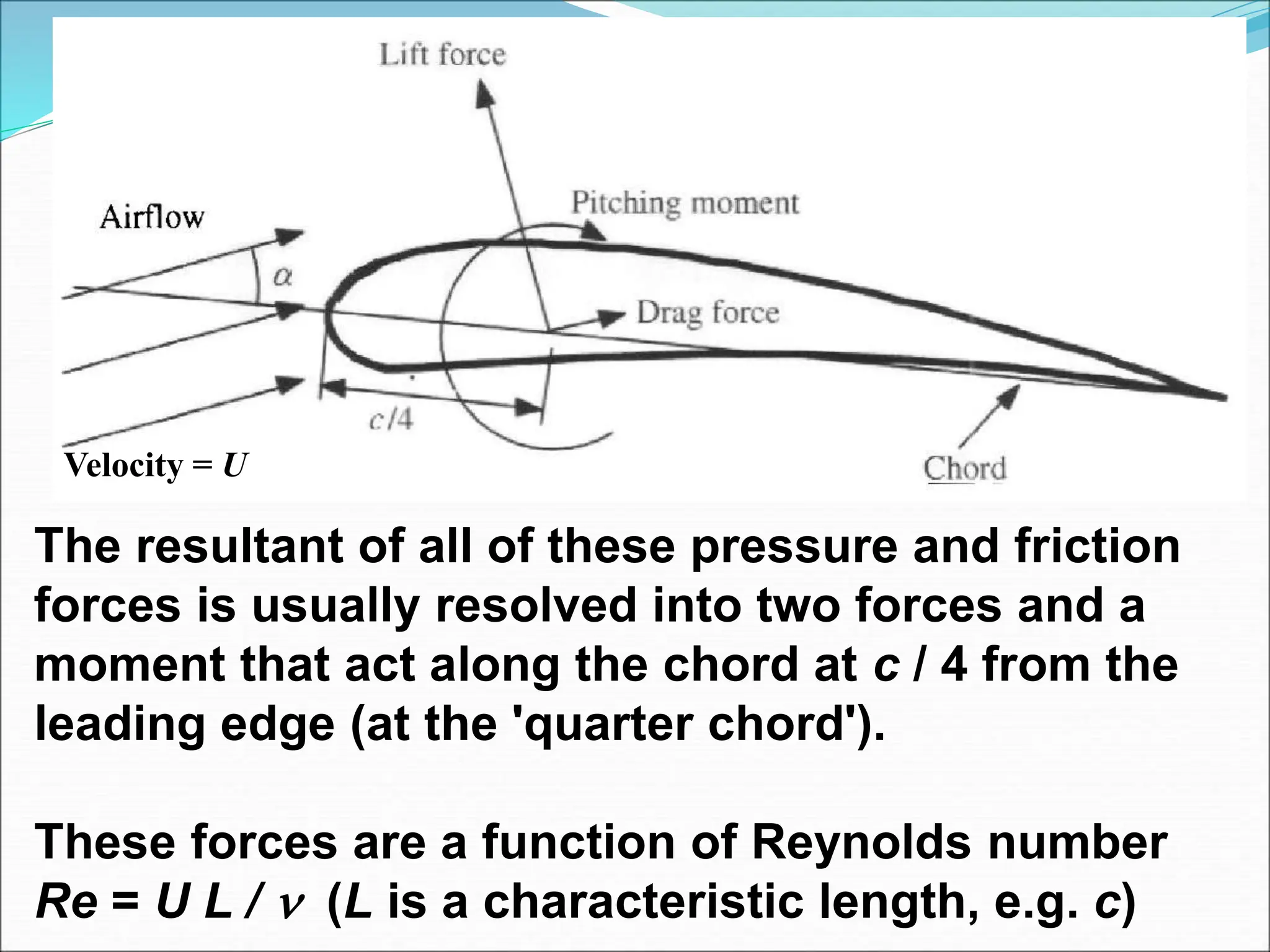

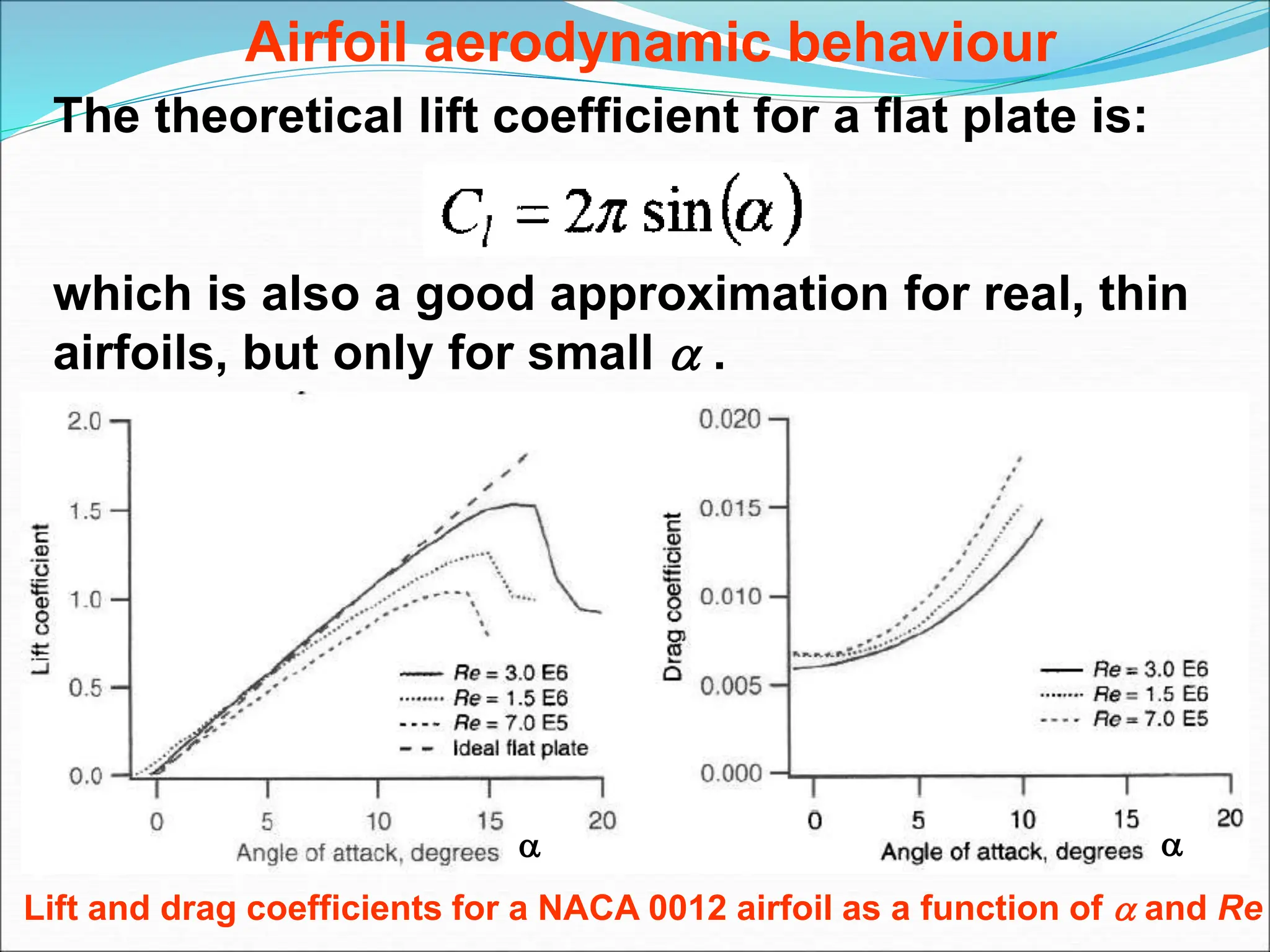

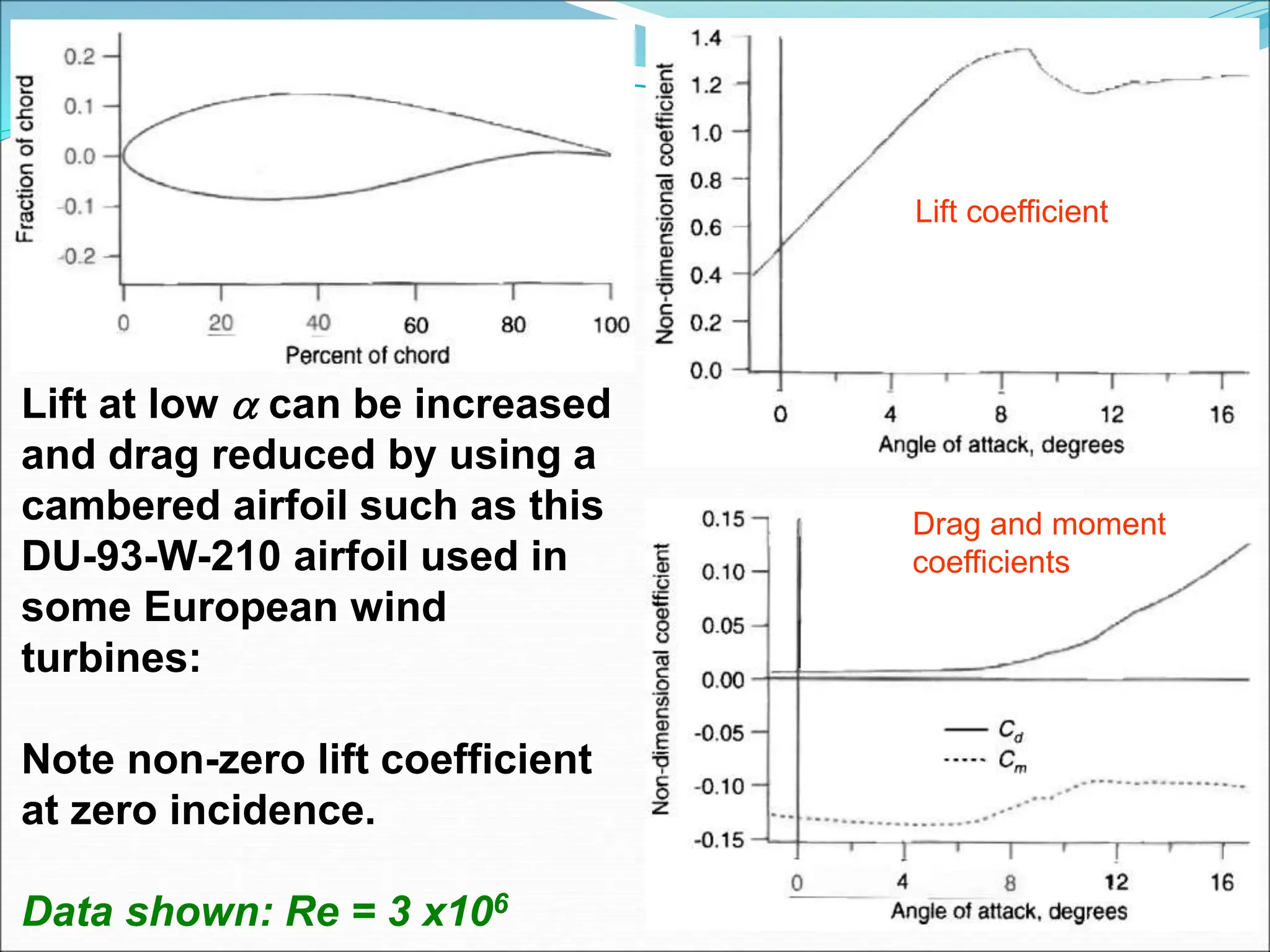

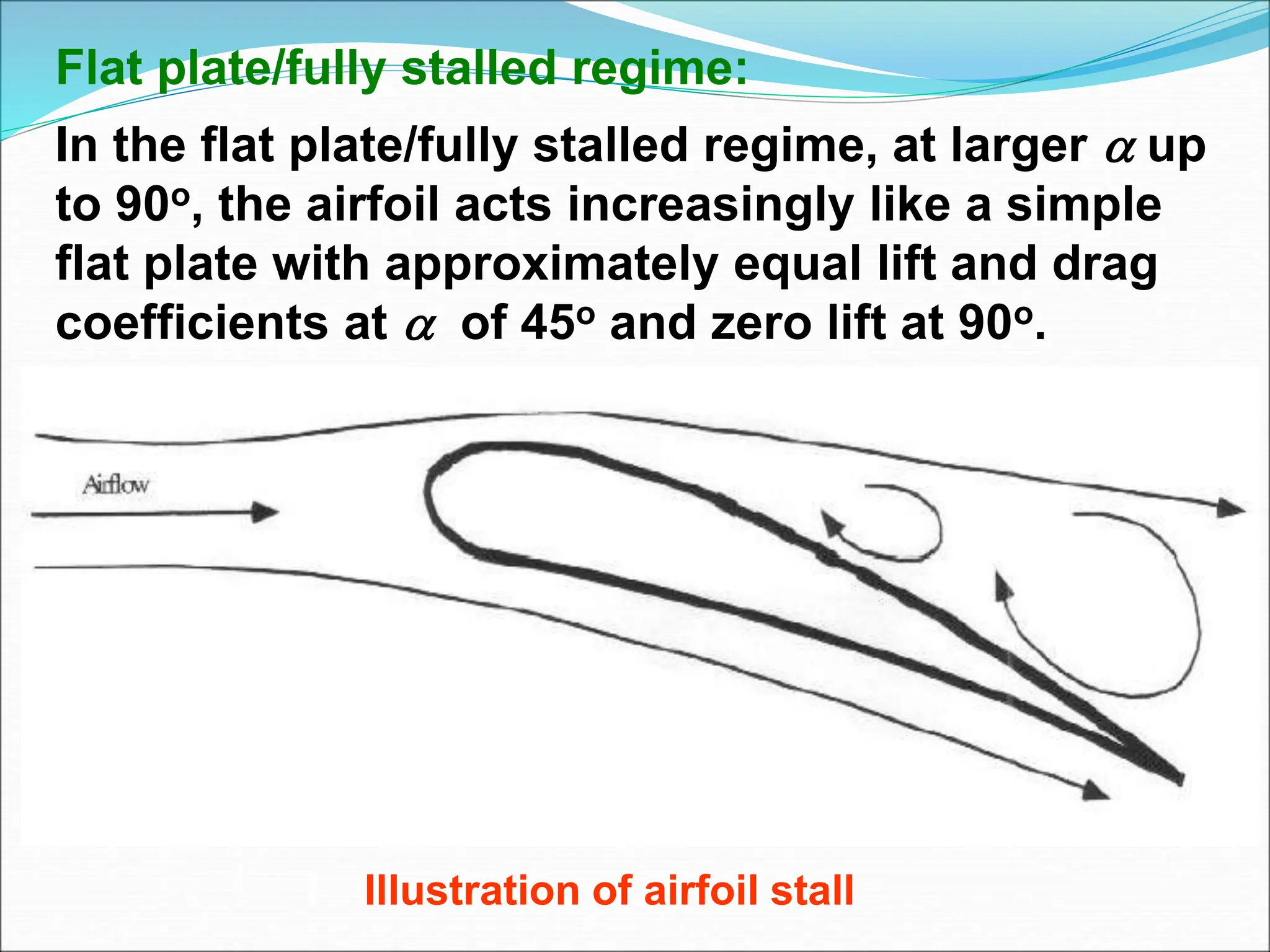

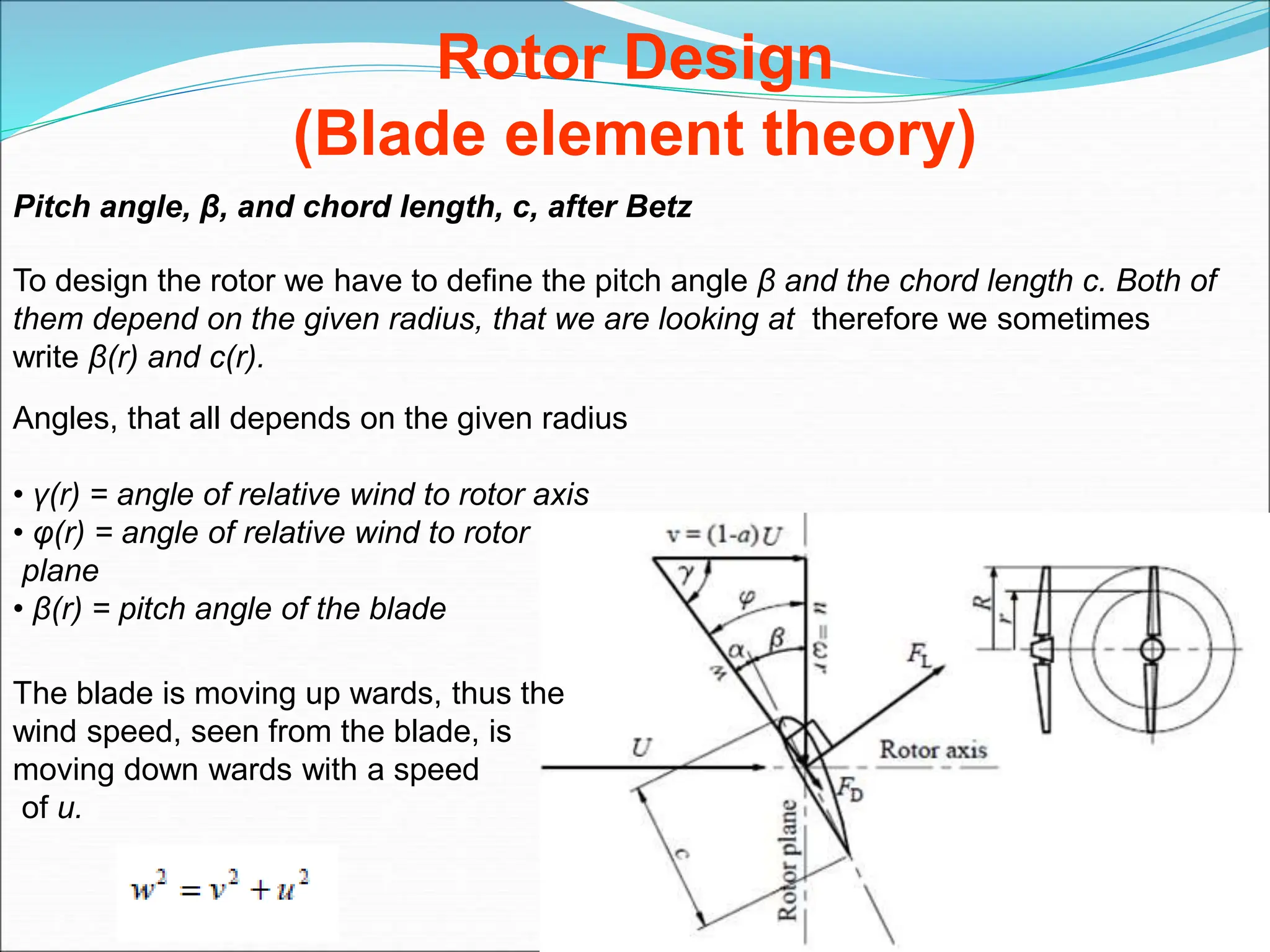

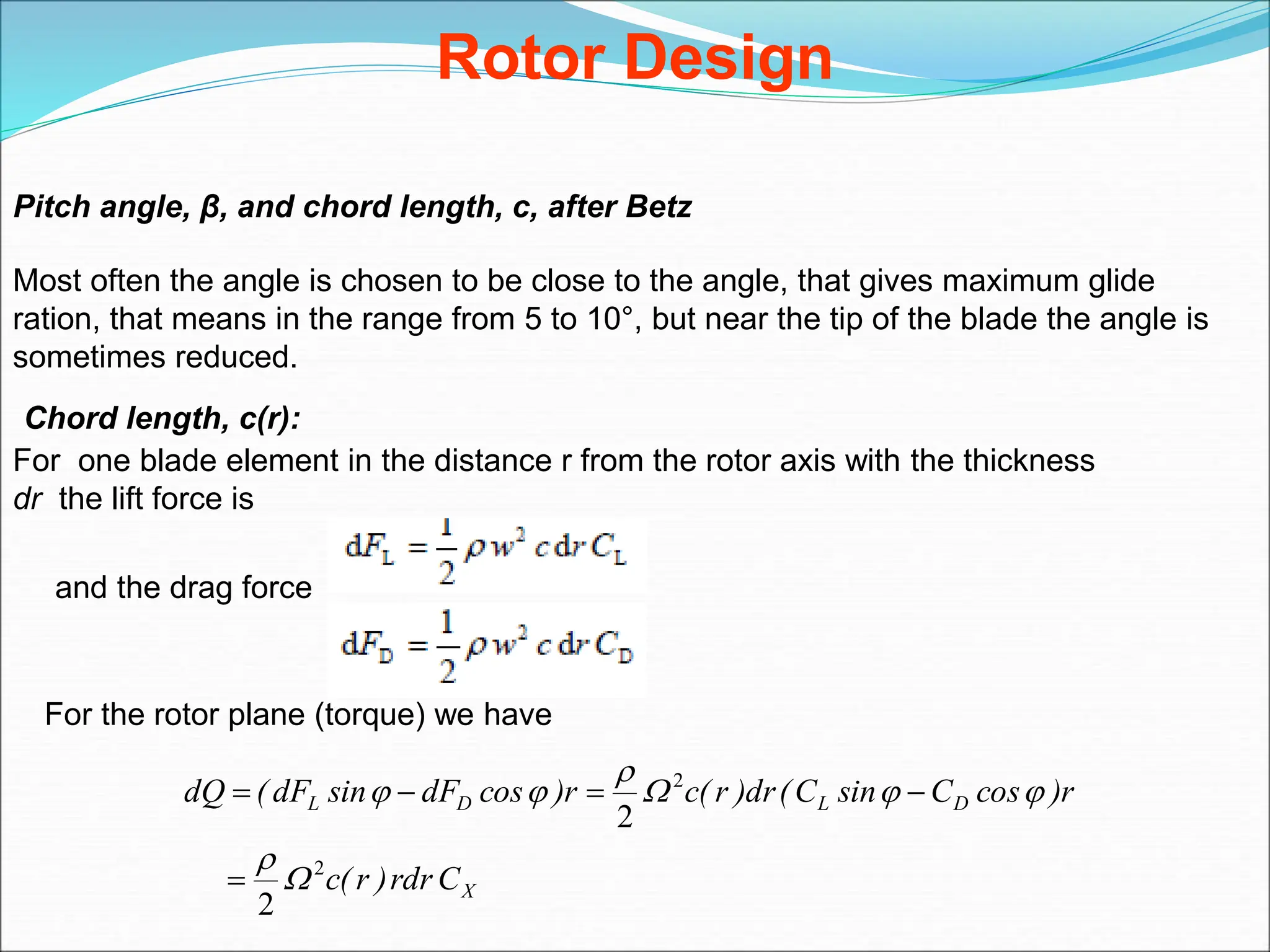

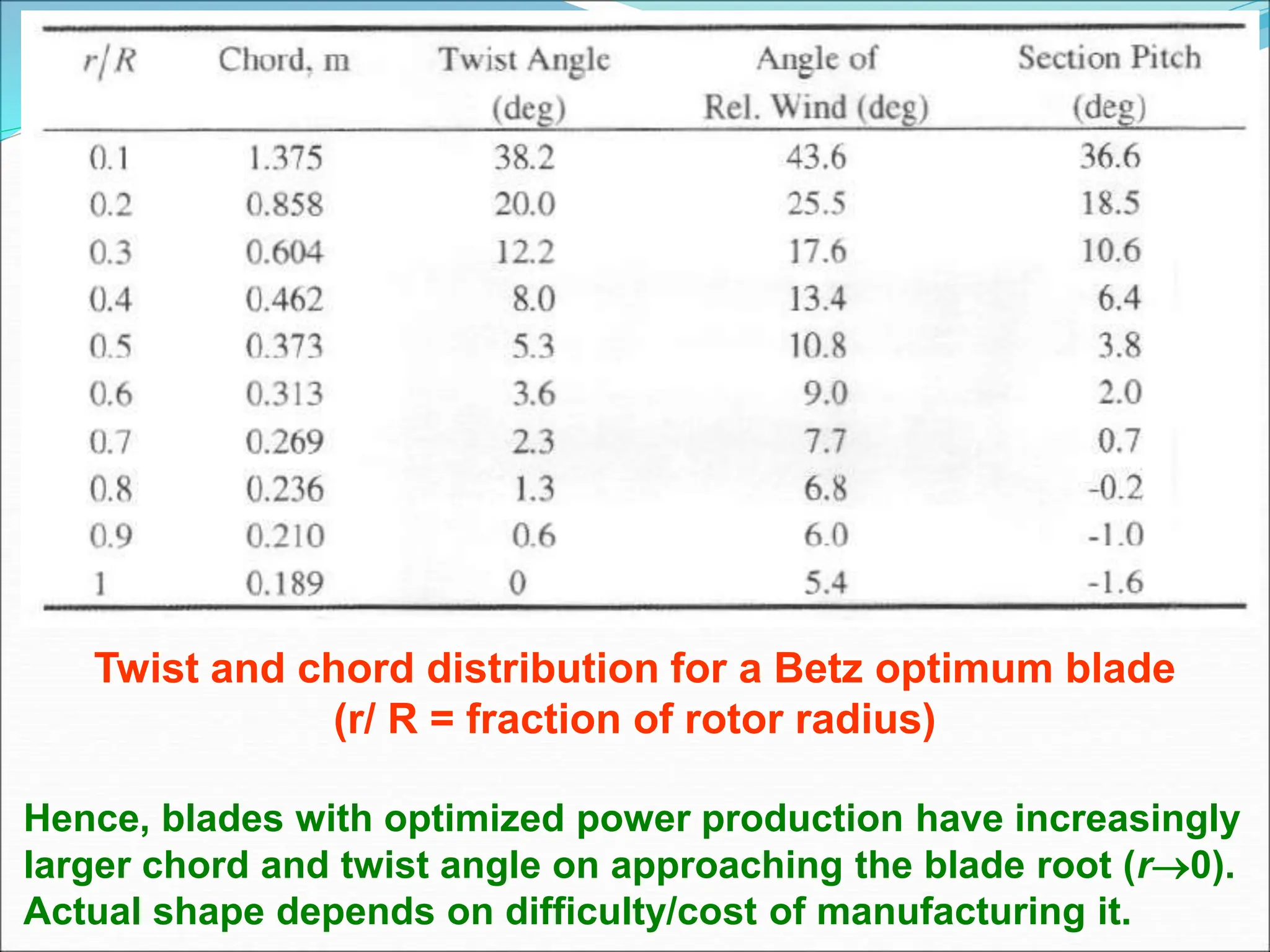

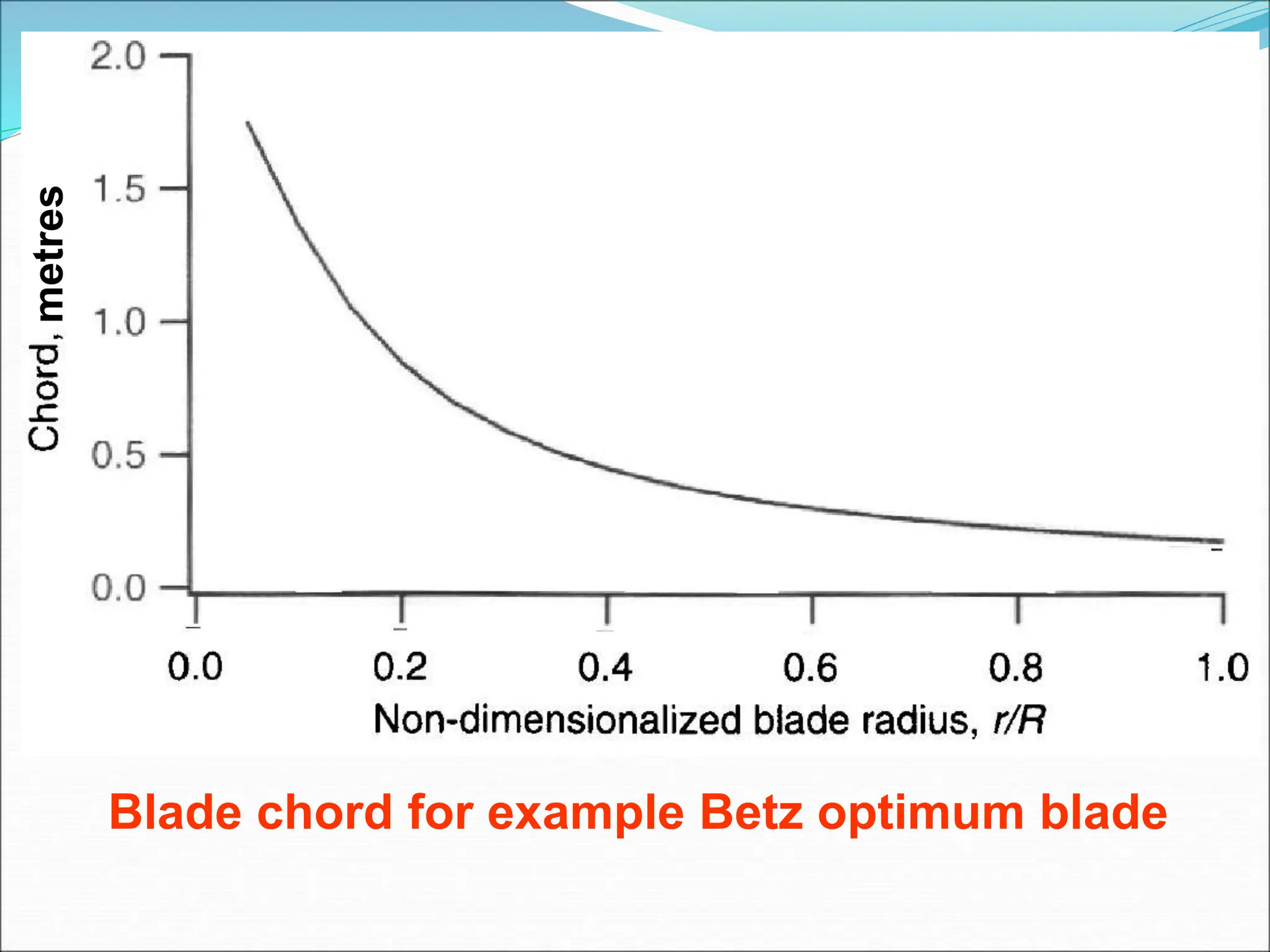

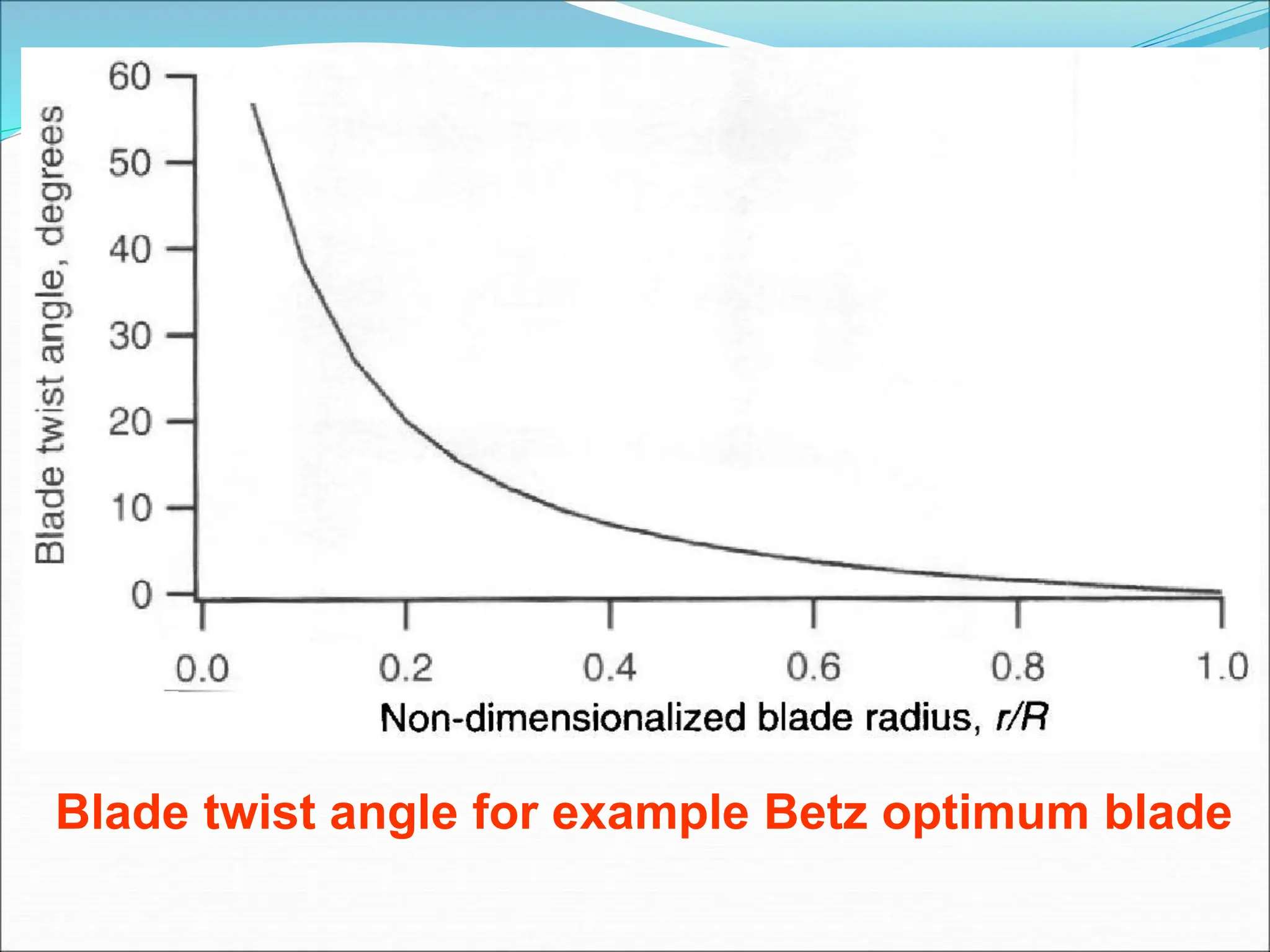

This document discusses the aerodynamics and design considerations of wind turbine airfoils, highlighting the importance of airfoil shape in optimizing mechanical power production. Key concepts such as lift, drag, and the effects of various aerodynamic parameters on turbine performance are explained, alongside historical design trends and their shortcomings. It emphasizes the role of blade element theory and momentum theory in analyzing and designing effective wind turbine blades.