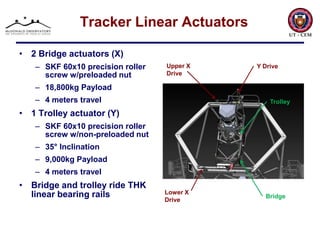

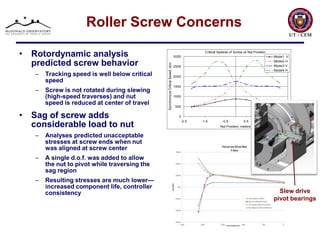

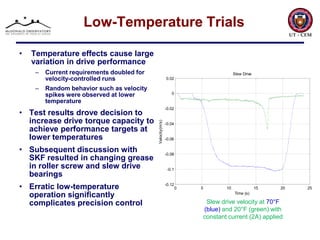

The document describes the linear drive design for the HETDEX project. It includes two bridge actuators and one trolley actuator using SKF 60x10 precision roller screws. Unique design considerations include slow precise positioning for tracking and high-speed coarse positioning for slewing. Components like long roller screws are prone to issues like sagging. Analysis was done to address concerns like rotordynamic instability and stresses. Low temperature testing showed performance degradation which informed design changes like increased drive capacity. Technical collaboration involved various engineers and manufacturers to meet requirements.