This document presents a systematic approach for designing an electrohydraulic drive tailored for aerodynamic testing in wind tunnels, focusing on reliability and controlled motion. It discusses the selection, testing, and qualification of various components, such as motors, bearings, and servo valves, essential for effective system performance. The paper concludes with a mathematical model in Simulink and emphasizes the relevance of choosing appropriate components for successful electrohydraulic systems.

![IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

_______________________________________________________________________________________

Volume: 04 Issue: 06 | June-2015, Available @ http://www.ijret.org 242

DESIGN PROCEDURE OF AN ELECTROHYDRAULIC DRIVE

Srishti Sharma1

, Ramesh R. Lekurwale2

, Amith Masade3

1

Department of Mechanical Engineering, K. J Somaiya College of Engineering, Mumbai, Maharashtra, India

2

Department of Mechanical Engineering, K. J Somaiya College of Engineering, Mumbai, Maharashtra, India

3

Manager, Product & Technology Development Centre, Heavy Engineering, Larsen & Toubro Ltd, Mumbai,

Maharashtra, India

Abstract

Aerodynamicists use wind tunnel to test models as well as for proposed aircraft components and engines. In order to keep these

models fixed in place for testing, ground based equipment is essential. Electrohydraulic drives form the back bone of such type of

mechanism which requires continuous motion for life time operations with controlled motion for start stop and bi-directional

motion mechanisms. Focus of this paper is on systematic approach for optimal designing of a typical electrohydraulic drive that

will provide roll motion to the testing model with emphasis on reliability of the system. This paper further highlights the design,

selection, testing and qualification procedures of different elements of the drive and the electrohydraulic drive assembly as a

whole.

Keywords - Design, Develop, Electrohydraulic roll drive, Spindle.

--------------------------------------------------------------------***------------------------------------------------------------------

1. INTRODUCTION

The modern technology and ever demanding need for the

design of newer means to test models in wind tunnel has led

to significant developments in the area. With the increase in

demand of large appendage deployment and several tracking

mechanisms; the application of electrohydraulic drives has

increased exponentially. Hydraulic servo systems can

generate high forces also exhibit rapid responses, and have a

high power-to-weight ratio compared to other technologies.

On the other hand, they have a significant nonlinear

behavior due to the nonlinear flow/pressure characteristics,

oil compressibility, time varying behavior, nonlinear

transmission effects, flow forces acting on spool and

friction, which is not only largely uncertain but is greatly

influenced by external load disturbances. Hydraulic systems

are mechanically “stiffer”, resulting in higher machine

frame resonant frequencies for a given power, high loop

gain and improved dynamic performance. They also have

the benefit of being self-cooled since the driving fluid

effectively acts as a cooling medium carrying heat away

from the actuator and flow control components [1]. Quality

and reliability aspects are of prime importance at each stage

[2]. Every component whether designed or selected is

checked for various aspects related to the requirement and

chosen such that the complete design is compact and

accurate. The roll drive is very important from aerodynamic

testing point of view as well as to hold the model in correct

and steady position for testing at various roll ranges.

2. PROBLEM DEFINITION

The paper discusses design of a roll drive that would roll at

a specific rate and for a specific roll range by overcoming

the aerodynamic forces and moments acting on the roll

drive. In order to design a roll drive the various mechanical

and electrical devices conceptualized are the sting, pod,

motor/actuators, bearings, feedback devices, hydraulic

cylinders, servo valves, seals, retainers, bolts, etc. Motors,

Bearings, feedback devices, valves, cylinders, seals and

bolts are the standard parts and were studied in depth with

the various classifications and types to choose the best as

per our requirement. There is a five axis manipulator with

Horizontal, Vertical, Yaw, Pitch & Roll motions. The

aerodynamic loads and moments act on the face of the roll

drive and can be seen as below:

Table 1: Aerodynamic Forces and Moments acting on the

Roll drive.

Forces/Moments Symbol Unit

Normal Force Fn N

Axial Force Fa N

Side Force Fs N

Pitching Moment Mp Nm

Yawing Moment My Nm

Rolling Moment Mr Nm

Accuracy of the roll required is ±0.05 degrees or better. The

roll range is of -90⁰ to +90⁰, whereas the roll rate is 0-25

rad/sec at variable rate.

3. DESIGN & DEVELOPMENT

3.1 Motors/Actuators

The very first system required to conceptualize the roll drive

is a motor/actuator. There were three concepts that were

realized to achieve this type of motion namely (a) Direct](https://image.slidesharecdn.com/designprocedureofanelectrohydraulicdrive-160906090846/75/Design-procedure-of-an-electrohydraulic-drive-1-2048.jpg)

![IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

_______________________________________________________________________________________

Volume: 04 Issue: 06 | June-2015, Available @ http://www.ijret.org 243

Electric drive (b) Gearbox with Electric Drive (c) Gearbox

with Hydraulic Drive.

(a) Direct Electric Drive: There exist various electric

drives but there are specifically three drives that are

used for aerospace related applications [2] and can be

listed as :

Brush DC motors

Brushless DC motors

Stepper or Servo motors

Based on the comparison between the drives and

advantages of the servo motor for the need of the

application we choose the Servo Motor from make

such as Moog or Rexroth to fulfill the space

requirements, torque and size parameters.

(b) Gearbox with Electric Drive: The limitation with the

direct drive is the bulkiness of the servo motor due to

which a gearbox was conceptualized with a motor of

lesser torque value such as Parker gearbox & motor kit,

or any other to reduce the size of the motor and fulfill

the torque characteristics.

(c) Gearbox with Hydraulic Drive: an alternative for an

electric drive is a hydraulic drive option which is

explored with a planetary helical gearbox. One may

choose Dan Foss hydraulic motor with a Parker

Gearbox to fulfill the functional requirements.

To choose the best available option for the drive a decision

matrix was made on the basis of few engineering parameters

[3] and can be seen as in the table below:

Table 2: Decision Matrix

PARAMETERS

DIRECT

ELECTRI

C DRIVE

ELECTRI

C DRIVE

WITH

GEARBO

X

HYDRAULI

C DRIVE

WITH

GEARBOX

FUNCTIONAL

REQUIREMEN

T

2 2 2

OPERATIONA

L SAFETY

2 2 2

EASE OF

ASSEMBLY/

DISASSEMBL

Y

2 1 0

RELIABLITY 2 2 2

FEASIBLITY 2 2 2

ACCURACY 2 1 1

PROCUREMEN

T

0 1 2

COST 0 1 1

AESTHETICS 2 1 0

WEIGHT 0 1 1

SPACE

REQUIRED

0 1 2

OIL LEAK IN

VACUUM

2 2 0

EMI/EMC 0 0 2

TOTAL 16 17 17

Weightage: 0-Undesirable, 1-Desirable, 2-Most Desirable

Although there is an equal score of option (b) & (c) we

choose the option (c) due to EMI/EMC issues [4] with the

electric motor and the sensors and force balances that will

be attached on the prototype for testing. A Rotary Hydraulic

Actuator which incorporates many quality features including

precision ball bearings to provide shaft support, externally

removable gland for ease of seal replacement and cylinders

honed to a 10 micro inch finish to ensure long seal life

giving the required torque specifications at feasible pressure

values is selected.

3.2 Bearings

The selection of bearings and sizing the model according to

the specifications is of importance in order to balance the

forces and the moments. The classification of bearings can

be seen as below [5]:

Table 3: Characteristics table for choosing Bearings

Bearing

Type

Radia

l Load

Axial

Load

Accuracy

Low

Noise

Low

Frictio

n

Deep

Groove

Ball

Bearing

s

Good

Nor

mal

Normal

Very

Good

Very

Good

Crosse

d Roller

Bearing

s

Very

Good

Very

Good

Good Good

Very

Good

Cylindr

ical

roller

bearing

s

Very

Good

Good Good

Suffi

cient

Good

Taper

Roller

Bearing

s

Very

Good

Very

Good

Sufficien

t

Good Good

Spheric

al

Roller

Bearing

s

Very

Good

Good

Unsuitabl

e

Suffi

cient

Good

From the above table, choosing crossed roller bearings since

it is good with respect to all the parameters and is suitable

for our application. These bearings will be extremely critical

in the application to take the entire thrust load. In the Cross-

Roller Ring, cylindrical rollers are arranged crosswise, with

each roller perpendicular to the adjacent roller, in a 90⁰ V

groove, separated from each other by a spacer retainer. This

design allows just one bearing to receive loads in all](https://image.slidesharecdn.com/designprocedureofanelectrohydraulicdrive-160906090846/75/Design-procedure-of-an-electrohydraulic-drive-2-2048.jpg)

![IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

_______________________________________________________________________________________

Volume: 04 Issue: 06 | June-2015, Available @ http://www.ijret.org 244

directions including, radial, axial and moment loads. Since

the Cross-Roller Ring achieves high rigidity despite the

minimum possible dimensions of the inner and outer rings,

it is optimal for applications such as joints and swivelling

units of industrial robots, swivelling tables of machining

centres etc. [6]. Crossed roller bearing was chosen for the

assembly in order to fix one end of the assembly (transfers

the thrust forces to the bottom or to the whole assembly) and

the other end fixed to the spindle such that it is free to rotate

and provide the desired angular motion. To support these

bearings we use radial ball bearings on the other end.

Crossed Roller bearings and radial ball bearings are

preloaded during manufacturing itself, pre-load values for

various rigidity levels are available in catalogue, and no

adjustment is possible during assembly unlike angular

contact bearings.

3.3 Load Calculations & Model Generation

One important standard part extremely critical in the

application because of the high speed, high temperature flow

region is a seal ( to avoid fluid leakage in environment and

from drying the bearings out of lubrication), U-Cup type of

seal has a maximum pressure range up to 40 MPa and would

be suitable for the design. Other non-standard part used is

the flange placed so that all the cables from prototype

sensors and force balances can be taken out from this flange

out to the main console for result evaluation. Standard bolts

selected according to the stress analysis on the assembly.

The assembly was then analyzed for loads & moments

acting on center of axis of the roll drive. Since the forces are

non-coplanar, vector mechanics is used to solve the forces

and moments in the three planes and a resultant used to

calculate the maximum value on the sting. The sting is taken

into consideration and loads and moments applied since it is

the rotating critical member of the assembly. Reactions on

the points where the bearings are placed are calculated using

simple engineering mechanics. Of the three planes yaw &

pitch planes are considered for force calculations, and

making shear force & bending moment diagrams for each

plane [7]. Now the forces and moments on each point on the

two planes are summed up using vector mechanics. With the

shear forces and bending moments now combined at each

point on the spindle, weakest section of the member is taken

and designed for failure.

With the load ratings of the bearings from respective bearing

catalogs, Basic life and Safety factor of the bearings is

calculated for optimum performance of the bearings without

failure during operation. The CAD model was designed

using SEIMENS PLM software NX 7.5. The cross section

of the complete assembly can be seen as below with the

details of the various parts.

Fig 1: Cut sectional view of the Assembly

3.4 Feedback Devices

In order to determine the true position of the output shaft of

the electrohydraulic drive, a position sensor is required.

There are several types of position sensors available and

each has its own merit and demerits [2]. They can be listed

as below:

Table 4: Characteristics table for choosing Position Sensor

Description Resolver Optical

Encoder

Rotary

Potentiomet

er

Accuracy High High Moderate

Reliability Very High High Moderate

Availability All Sizes All Sizes All Sizes

Cost High Moderate low](https://image.slidesharecdn.com/designprocedureofanelectrohydraulicdrive-160906090846/75/Design-procedure-of-an-electrohydraulic-drive-3-2048.jpg)

![IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

_______________________________________________________________________________________

Volume: 04 Issue: 06 | June-2015, Available @ http://www.ijret.org 245

Principal selection criteria for selection of Position sensors

are the accuracy requirements. Once the accuracy

requirements are established the type of position sensor is

selected based on ease of operation and cost. Thus, choosing

Absolute encoders with hollow shaft mounting having

number of turns of 24 bits having an SSI interface.

4. HYDRAULIC SERVO SYSTEM

A typical hydraulic servo system will have the following sub

systems and can be named as below:

1) Hydraulic Power Supply

2) Servo Valve

3) Hydraulic Actuator

4) Encoder

5) Servo Controller

From the above mentioned sub systems, hydraulic actuator

and encoder has already been discussed. The block diagram

to explain the system can be seen below:

Fig 2: Block diagram of a position controlled Hydraulic

Servo system

4.1 Servo Valve

There are two most important parameters on which the

selection & sizing of a servo valves [8] depends:

(a) Flow Requirement

Specified or Desired Actuator Speed

Limits by Pump flow

(b) Dynamic performance

Acceleration

Cycle time

Accuracy

The electro-hydraulic flow control valve acts as a high gain

electrical to hydraulic transducer, the input to which is an

electrical voltage or current, and the output a variable flow

of oil. The vast majority of flow control servo valves in

existence employ a double flapper nozzle pilot stage and a

single spool boost stage. A stiff feedback spring is generally

used to provide feedback from the boost stage to the pilot.

These types of servo valves tend to be difficult to

manufacture and expensive. A less conventional, less costly

type of flow control servo valve utilizes a two-spool boost

stage and a flapper nozzle pressure control pilot. Because a

feedback wire between the nozzle flapper pilot and the boost

stage is not needed, assembly is simplified [1]. In order to

size a servo valve its flow capacity should be calculated

with the actuator specifications so that it is not oversized or

undersized thereby reducing the system accuracy. An excel

sheet is made on these lines to size the servo valve whose

rated flow is estimated.

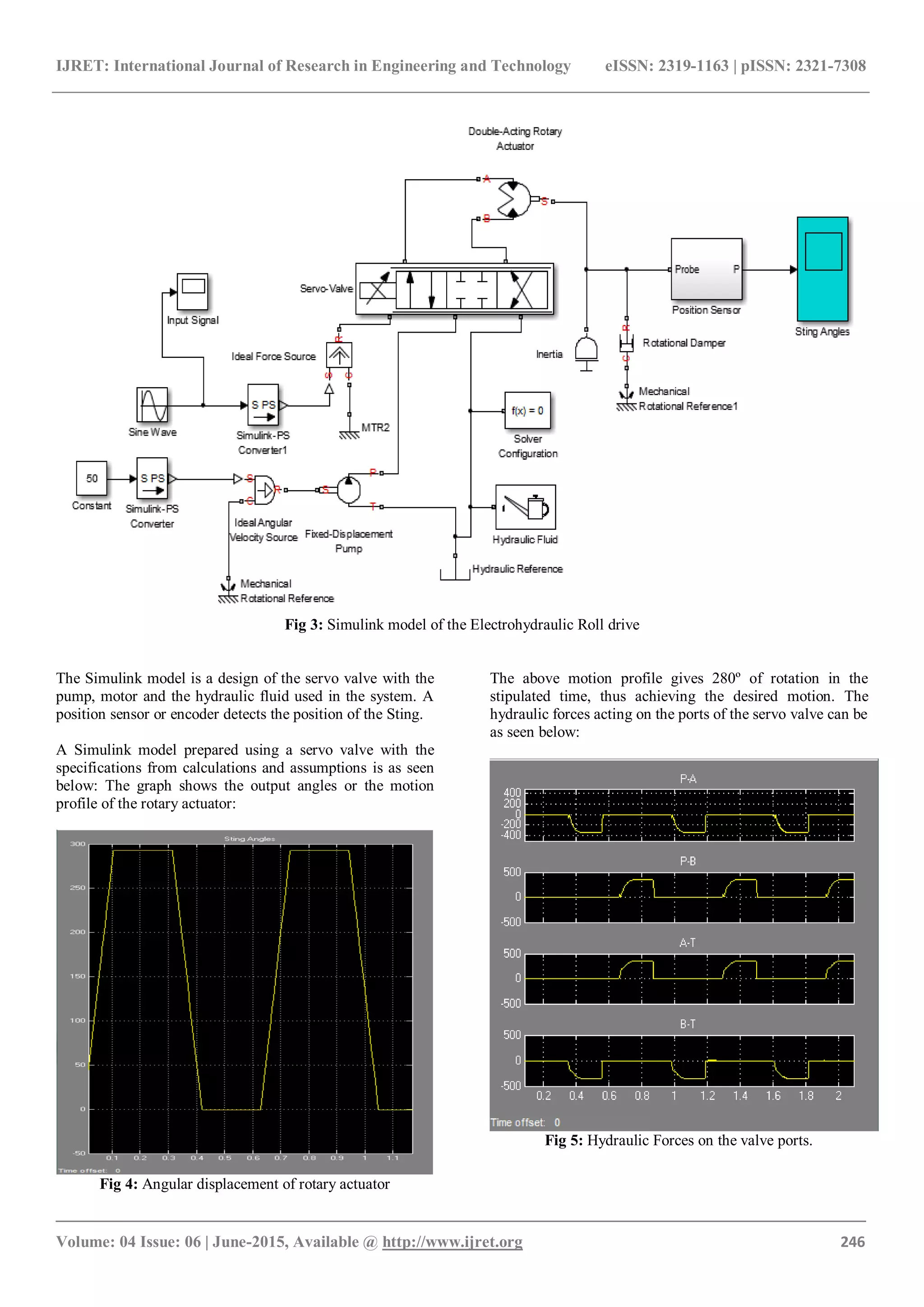

The servo valve with the complete system to produce a roll

motion can be seen as in the Simulink model:](https://image.slidesharecdn.com/designprocedureofanelectrohydraulicdrive-160906090846/75/Design-procedure-of-an-electrohydraulic-drive-4-2048.jpg)

![IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

_______________________________________________________________________________________

Volume: 04 Issue: 06 | June-2015, Available @ http://www.ijret.org 247

Thus the system operates typically with the desired angular

motion and the forces under permissible value. Therefore

the designed system follows a procedure that can be used to

design various such sub systems in robotic analysis and

research in order to achieve the desired motion.

5. CONCLUSION

1) This paper provides details of the criteria to be studied

during the selection of various standard components to

design an electro hydraulic system with the load

conditions and accuracy requirements.

2) The parameters to be considered for choosing an

electric or hydraulic drive are also summarised and the

block diagram for the complete position control of the

system is listed.

3) The paper includes the mathematical model of the

system in SIMULINK using MATLAB with a servo

valve for the controlled roll motion as well as the

output graphs of the desired angular position.

ACKNOWLEDGEMENTS

We are highly grateful to Prof. Sangeeta Bansode, K.J.

Somaiya College of Engineering and Mr. Arun

Ramchandani & Mr. Mahesh Verma, of HEIC, Larsen &

Toubro Ltd, Powai for giving the opportunity to carry out

our project and we acknowledge their help in reviewing the

Paper. We would like to express our gratitude to other

faculty members of Mechanical Engineering Department of

KJSCE, family and friends for providing academic inputs,

guidance and encouragement throughout this period.

REFERENCES

[1]. Vijaya Sagar Tenali, Simulation of Electro-hydraulic

Servo Actuator, masters diss., National Institute of

Technology, Rourkela, India, 2007.

[2]. Abhishek Kumar, Anoop Kumar Srivastava, K

Prakasha, and N Viswanatha, Design and Development of

an Electromechanical Drive for Spacecraft Mechanisms- A

Systematic Approach, 9th National Symposium and

Exhibition on Aerospace and Related Mechanisms (ARMS

2015), 2015.

[3]. Jose L. Salmerona and Florentin Smarandache,

Redesigning Decision Matrix Method with an

indeterminacy-based inference process, Pablo de Olavide

University at Seville (Spain), 2007.

[4]. B. Archambeault, O.M. Ramahi, C. Brench, EMI/EMC

Computational Modeling Handbook, Second Edition,

Kluwer Academic, 2001

[5]. Xiaofan Xie, Comparison of Bearings --- For the

Bearing Choosing of High-speed Spindle Design, 2003.

[6]. Naoki Yamaguchi, Motion System Design, NB Corp. of

America Hanover Park, III. 2010.

[7]. S. Ramamrutham & R Narayanan, Strength of materials,

Dhanpat Rai, 2008, 160-282.

[8]. Neal Hanson, “Selecting Proportional Valves And High

Response Valves”, Rexroth Bosch Group, 2006.](https://image.slidesharecdn.com/designprocedureofanelectrohydraulicdrive-160906090846/75/Design-procedure-of-an-electrohydraulic-drive-6-2048.jpg)