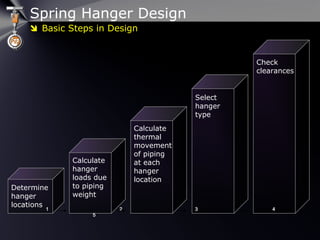

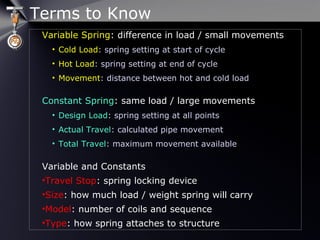

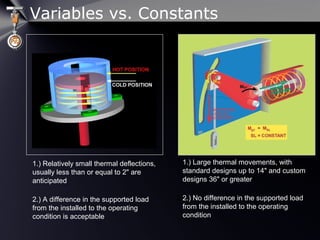

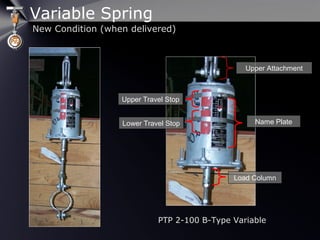

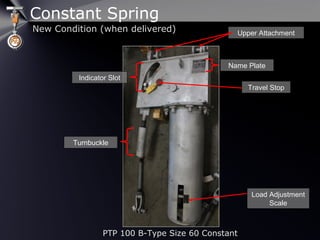

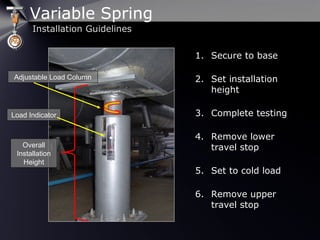

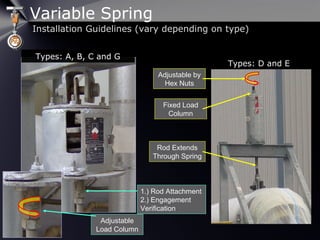

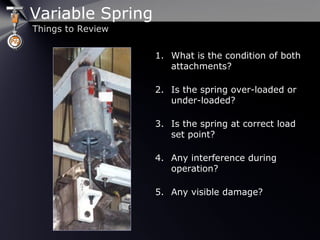

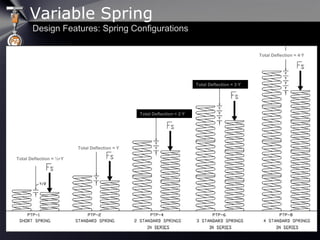

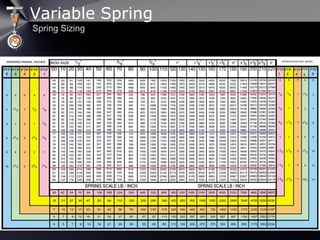

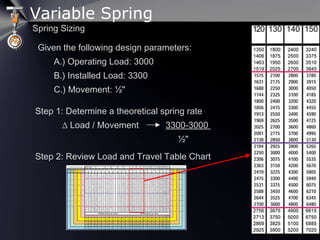

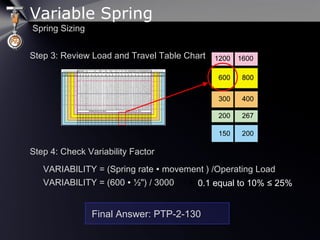

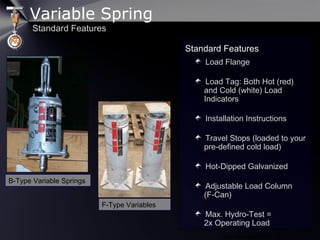

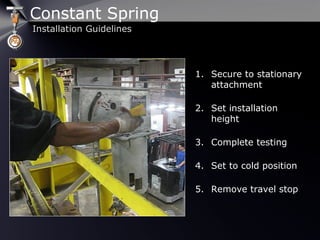

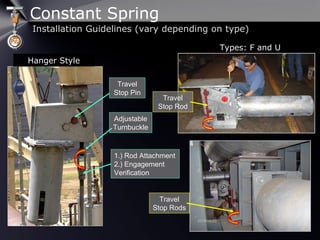

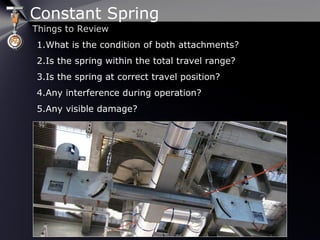

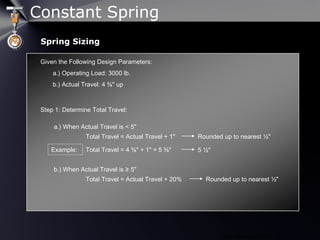

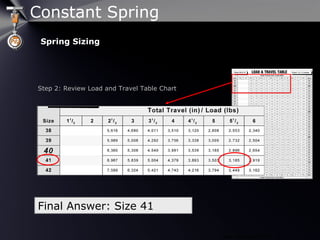

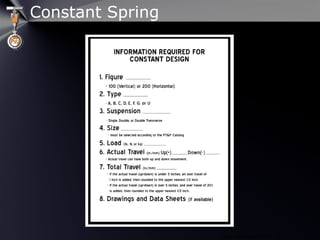

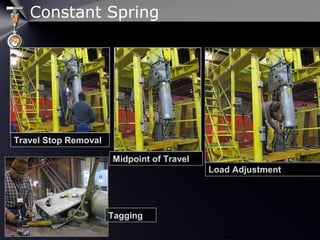

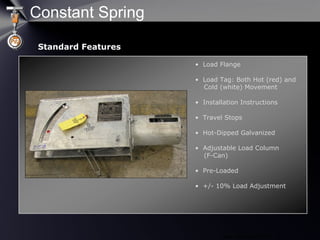

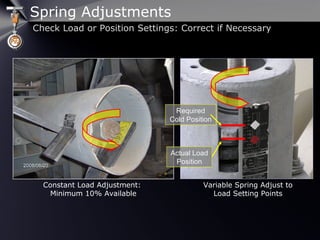

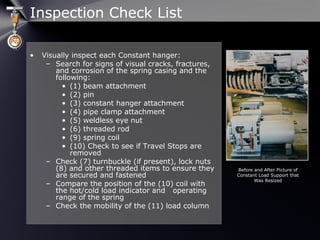

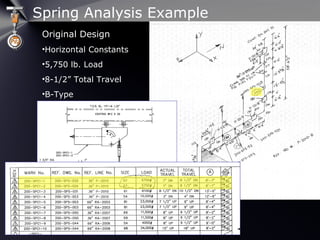

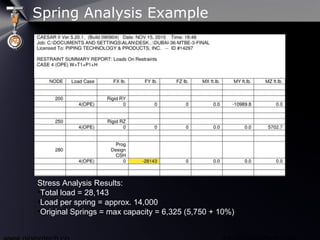

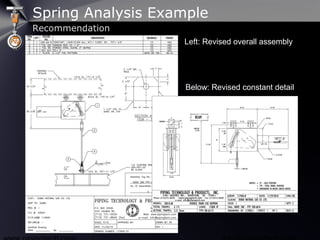

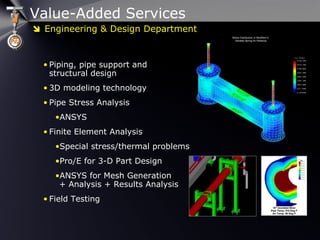

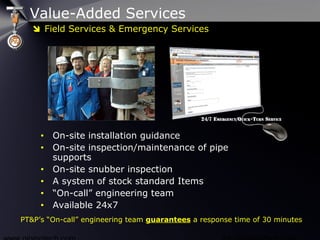

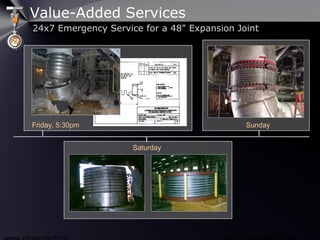

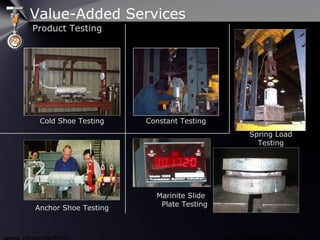

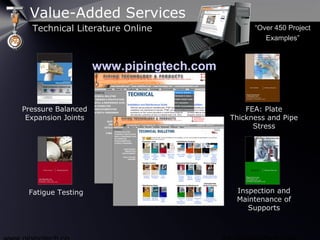

The document discusses engineered spring supports and their applications in piping systems, emphasizing their design, installation, and maintenance. It outlines types of springs, installation guidelines, and key considerations for ensuring operational efficiency and safety. Additionally, it highlights value-added services such as on-site inspections, emergency services, and product testing offered by Piping Technology & Products, Inc.