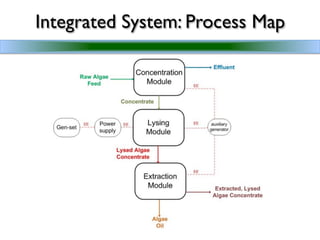

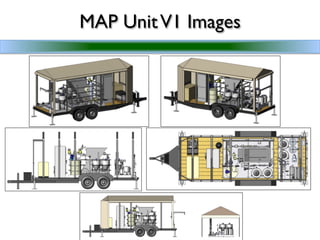

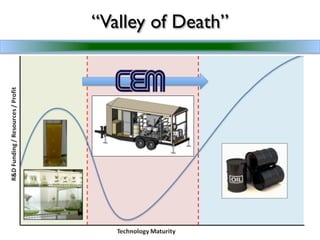

This document discusses the development of a mobile algae processing system. It notes that the algae biofuels industry currently lacks integrated processing technologies. The Center for Electromechanics has experience with process integration and bridging research to commercialization. They have previously scaled algae growth and tested concentration, lysis, separation and extraction technologies. The next step is to integrate these technologies into a demonstration-scale mobile unit capable of end-to-end algae processing up to several acres per day. This integrated system will demonstrate scalability and economics to help advance the algae biofuels industry.