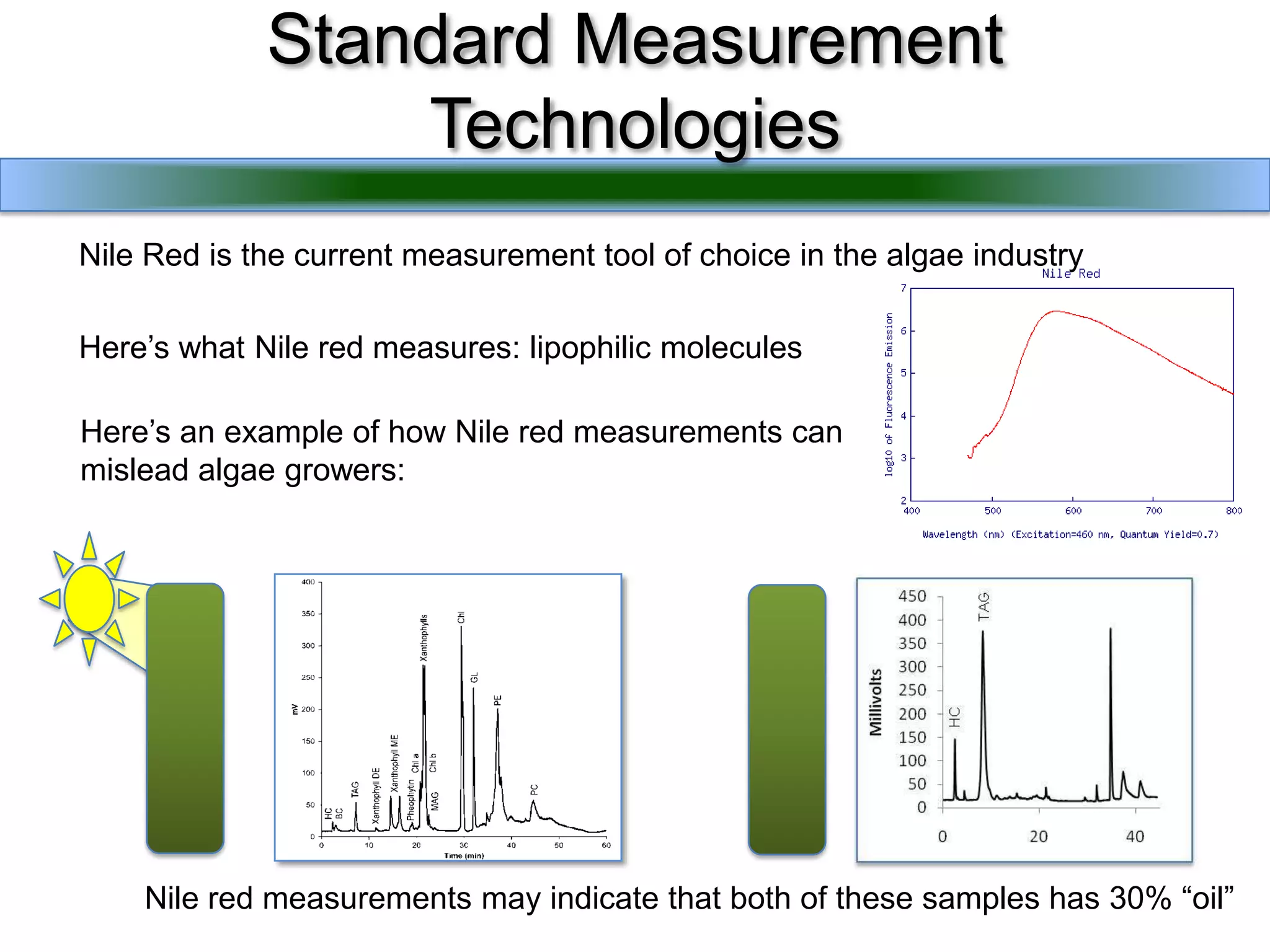

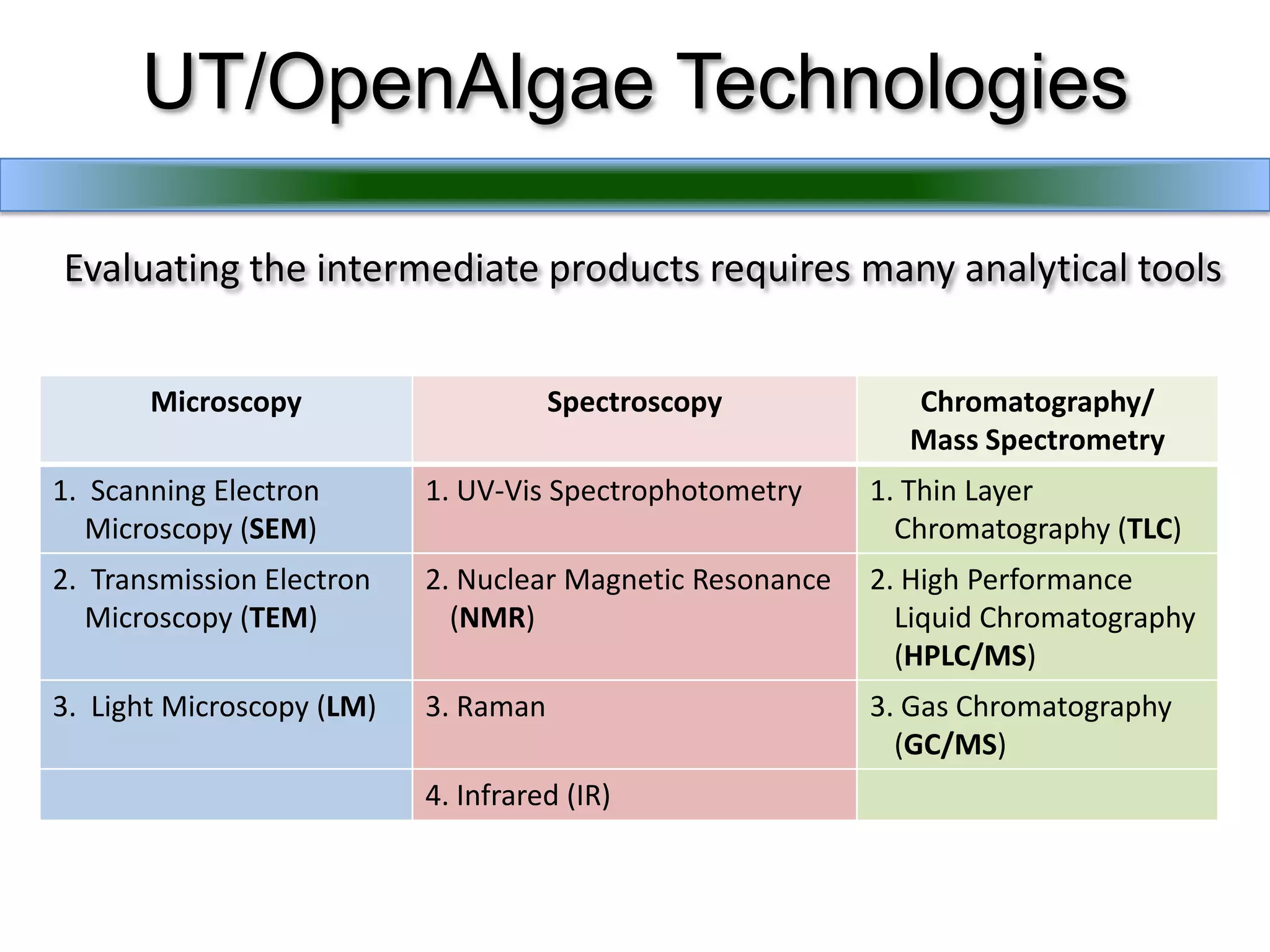

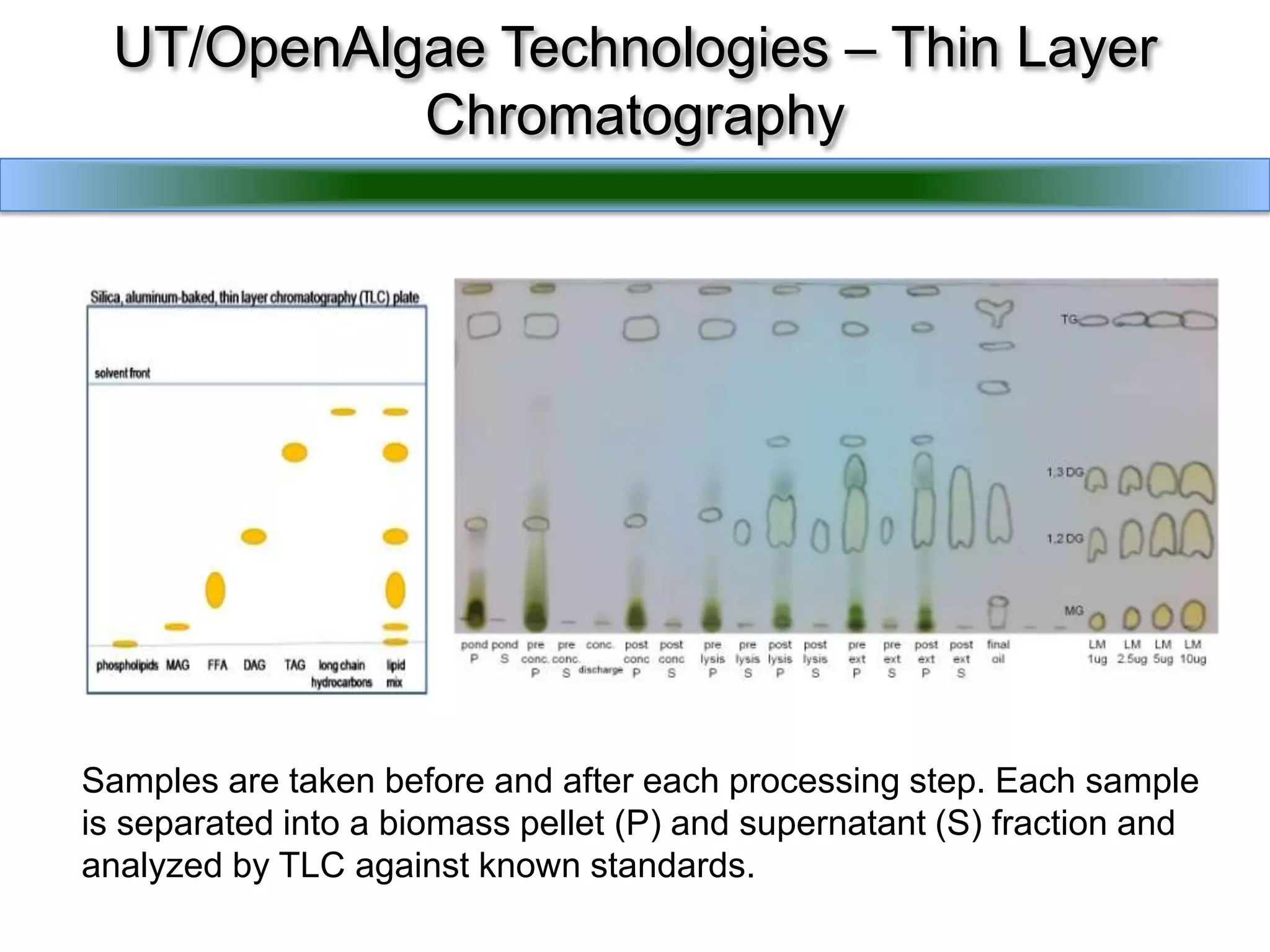

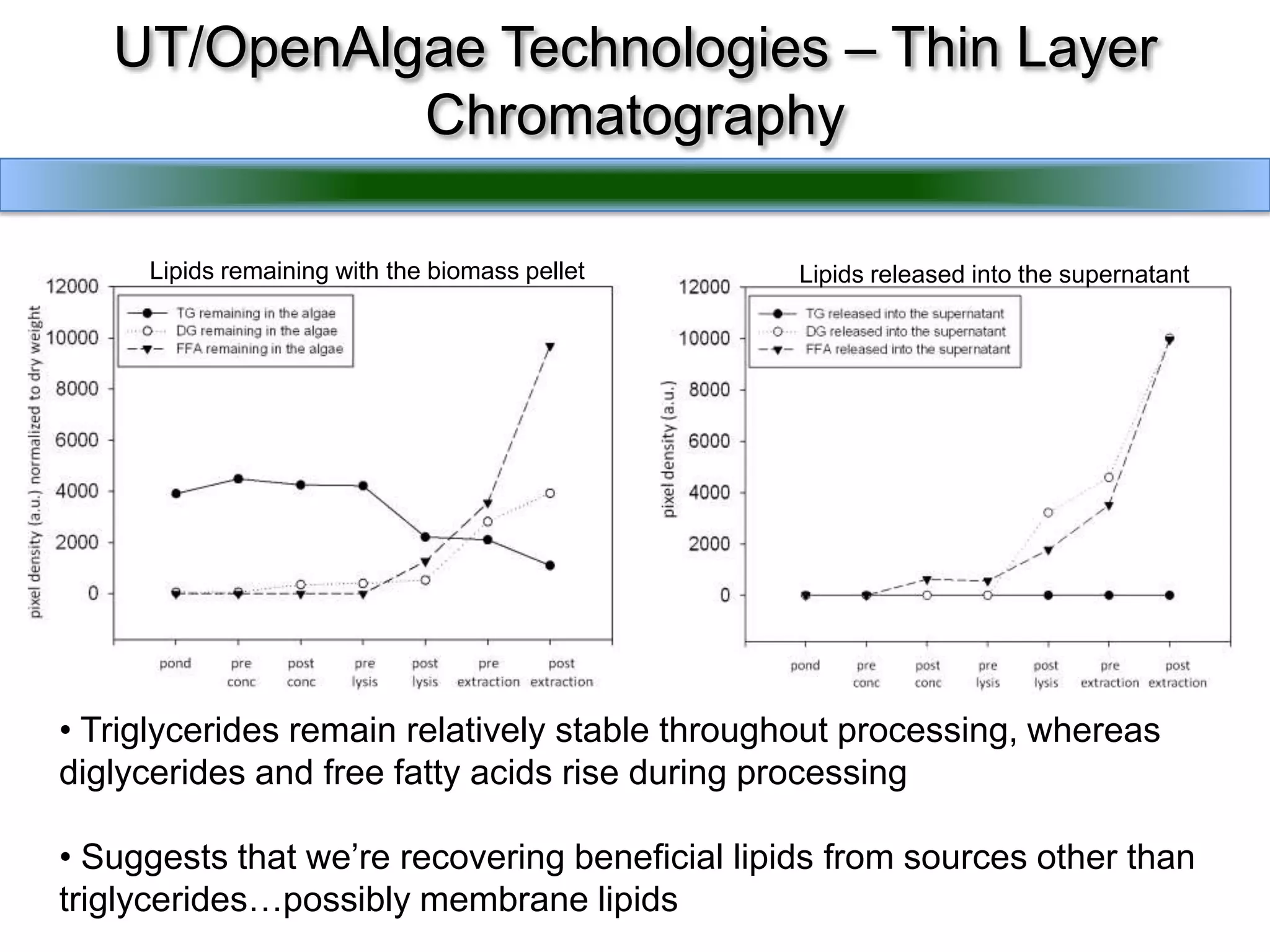

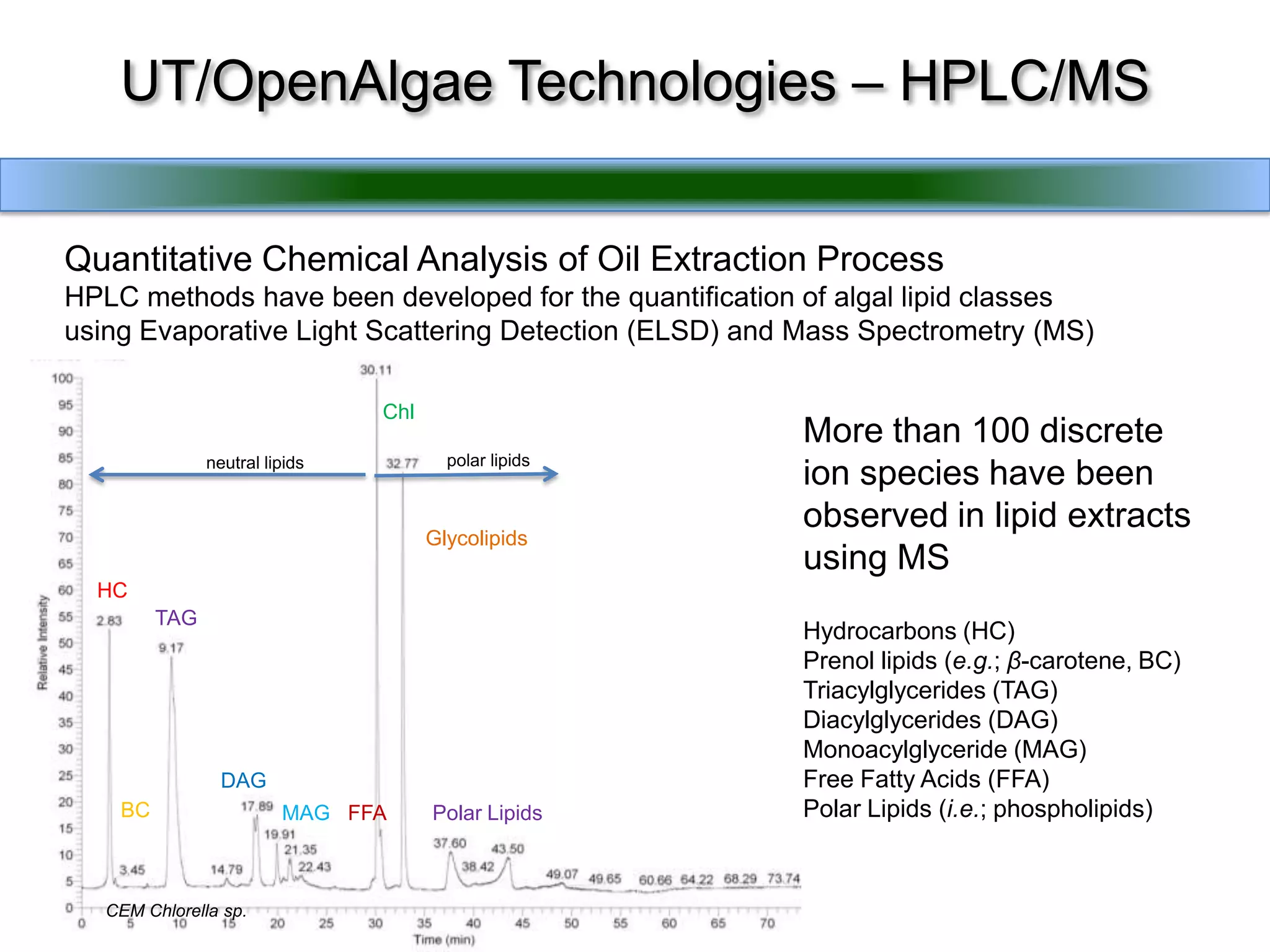

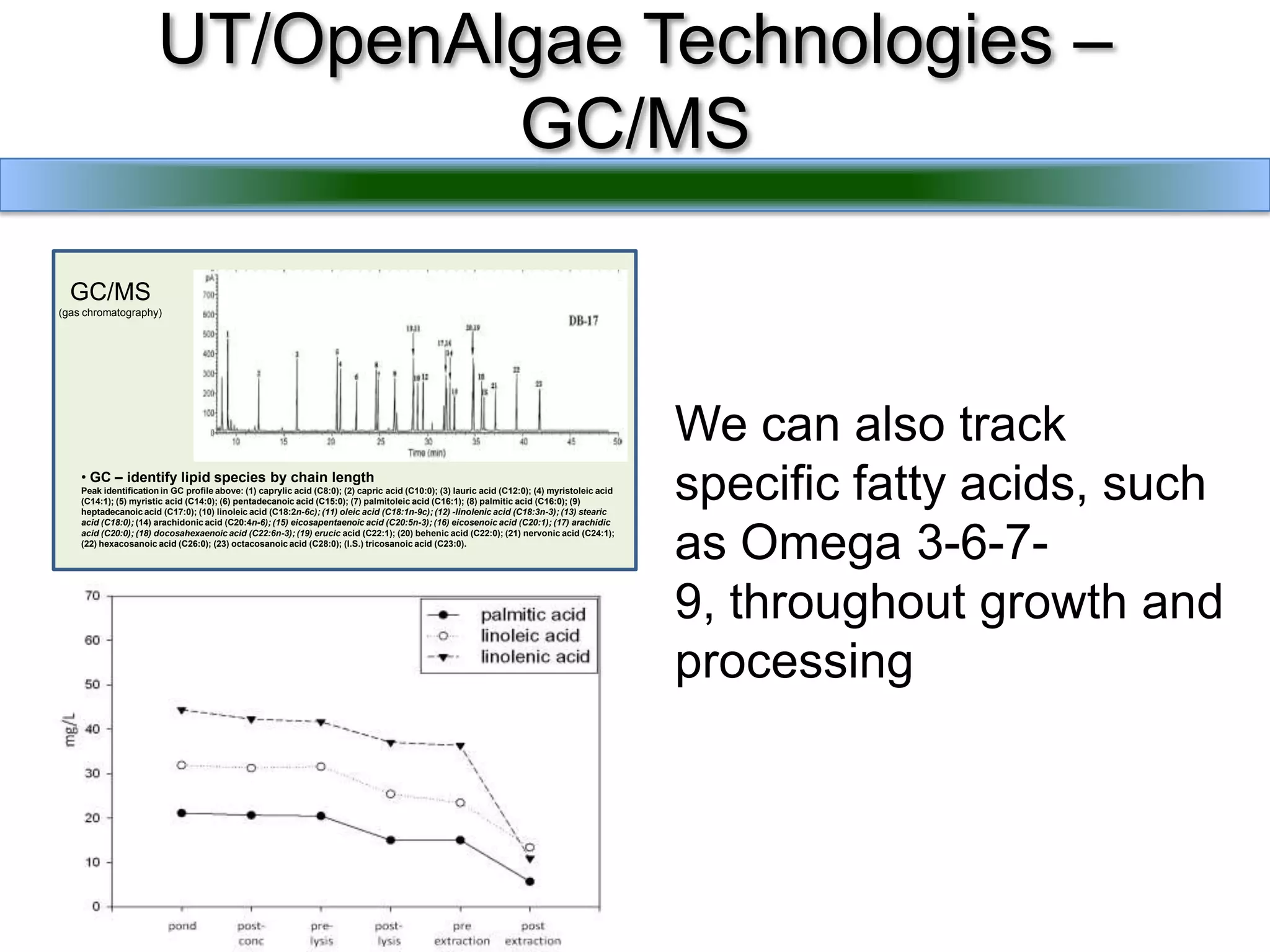

1) The document discusses analytical tools used to evaluate algae, including Nile red staining, thin layer chromatography, HPLC/MS, and GC/MS. These tools can provide more accurate measurements of lipids than traditional methods.

2) Technologies developed at UT/OpenAlgae allow individual measurement of lipids and tracking of fatty acids like omega-3 throughout growth and processing. This helps increase understanding of algal lipid dynamics.

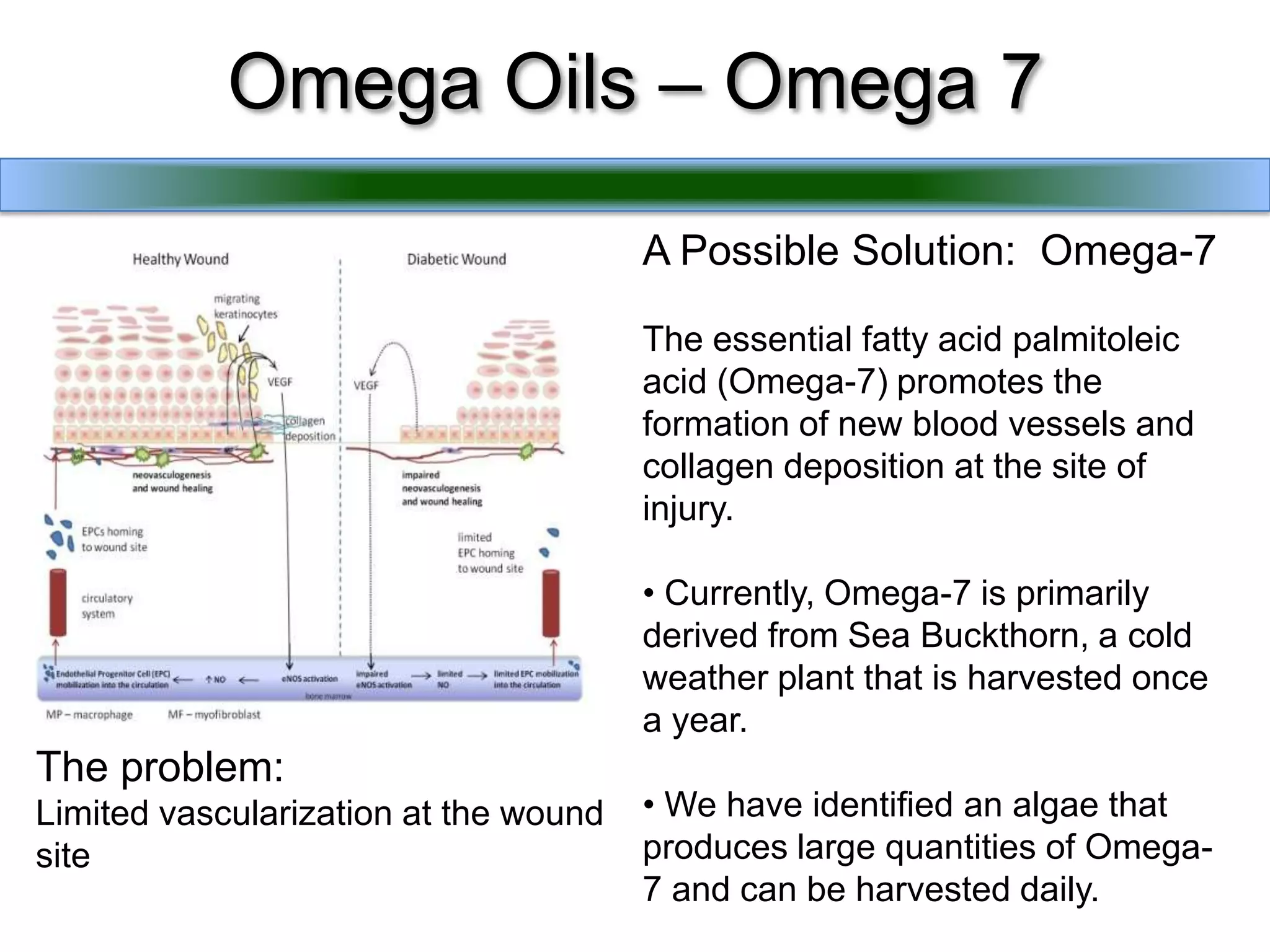

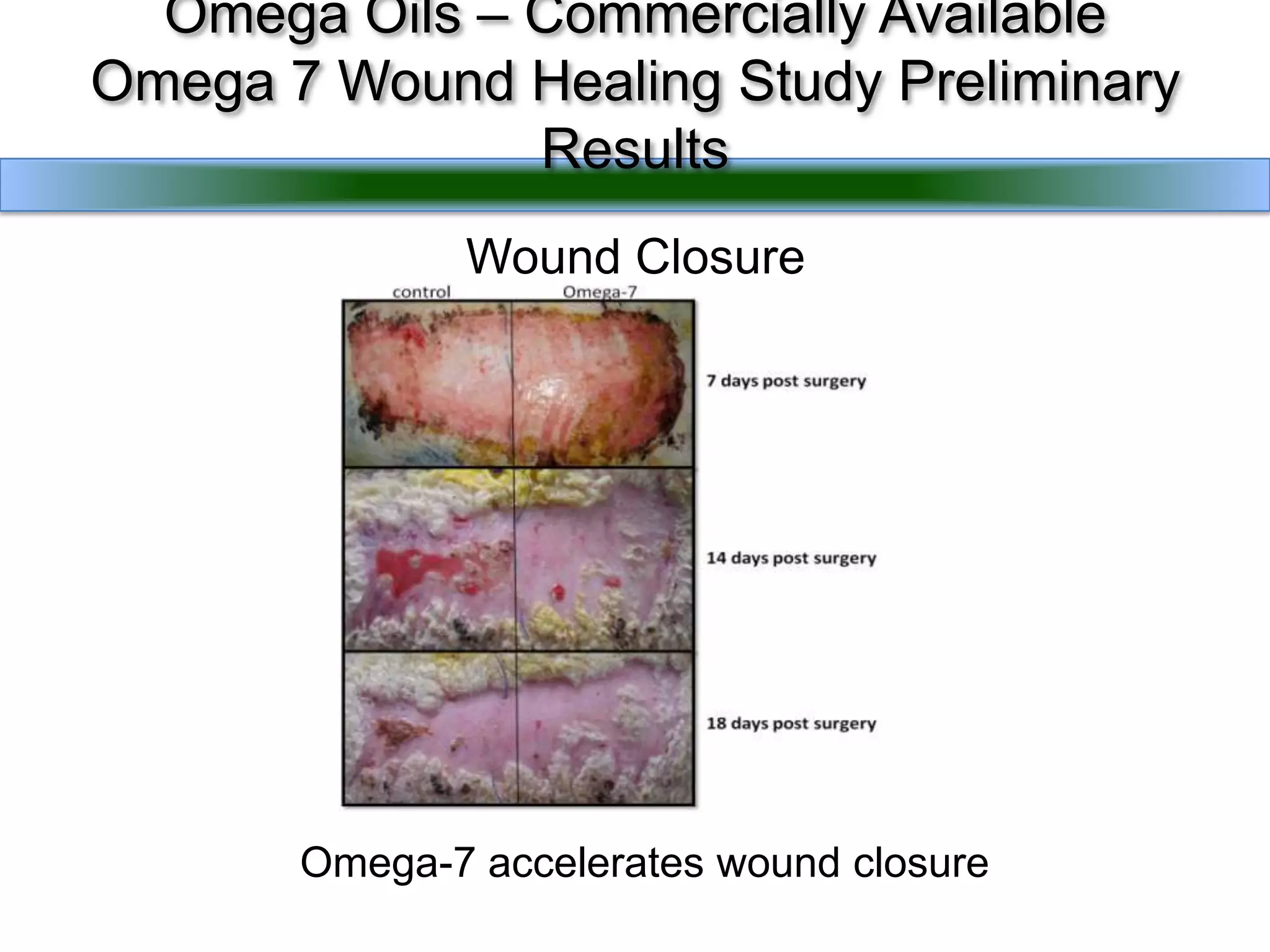

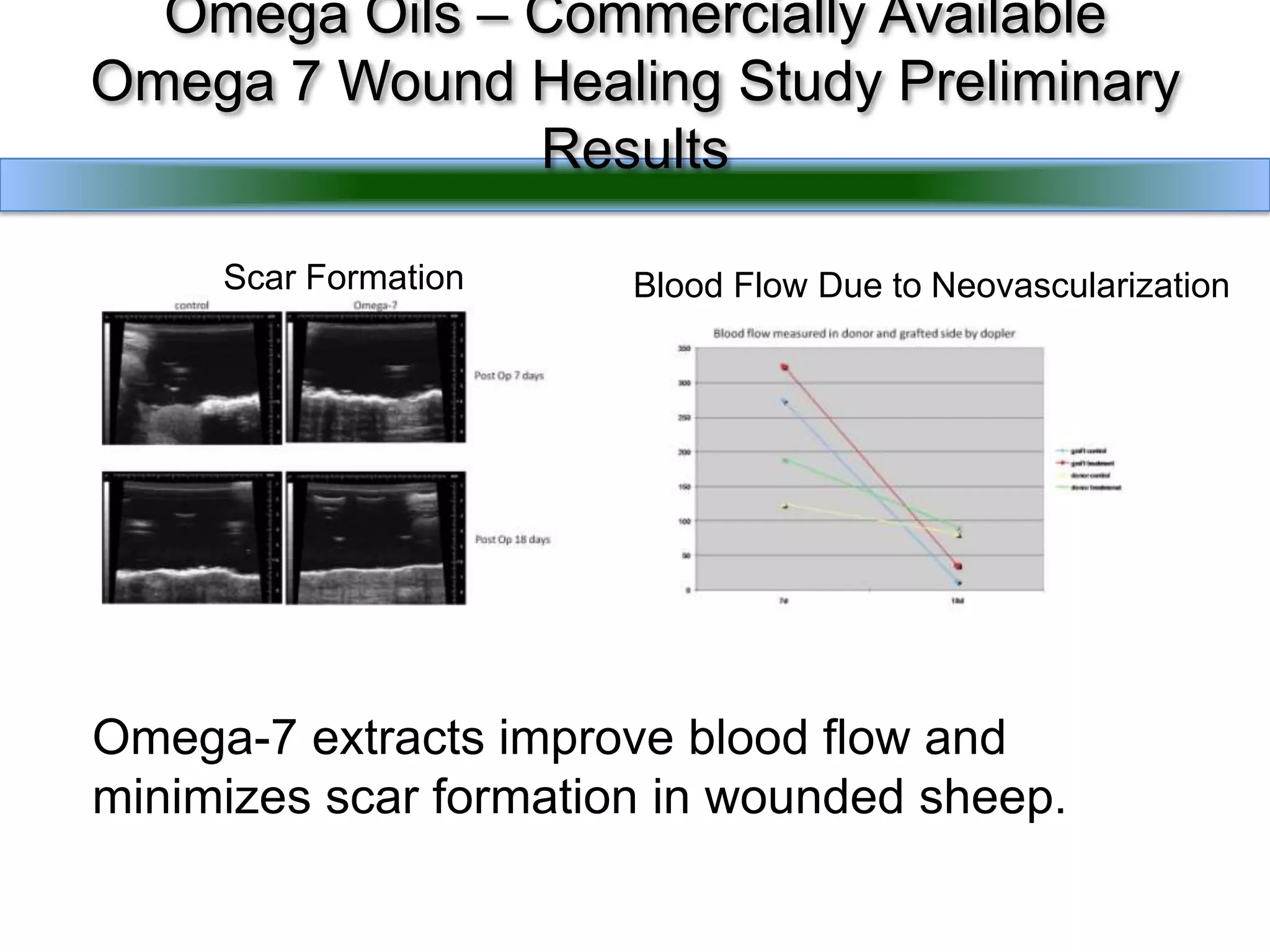

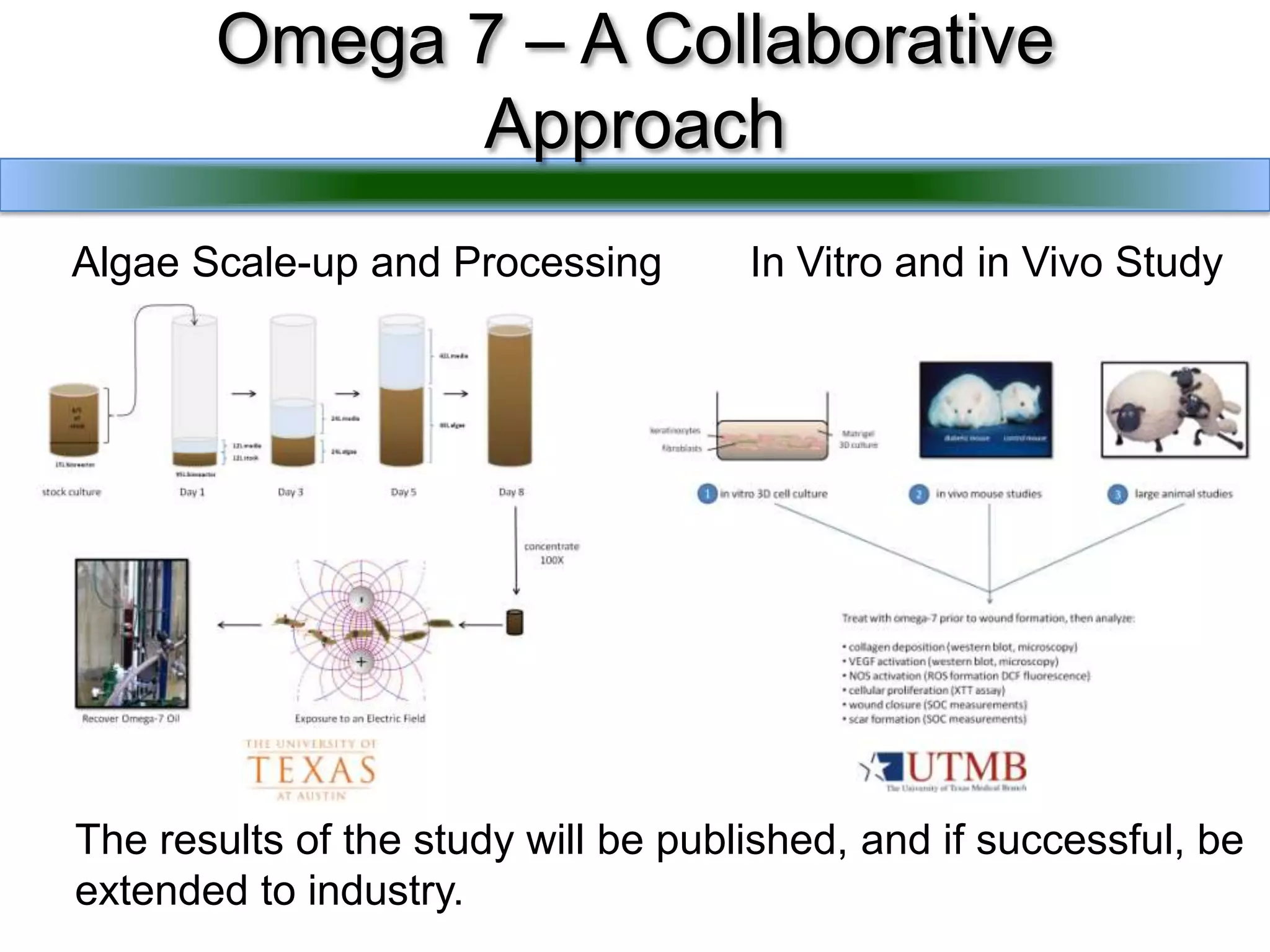

3) Preliminary results suggest algae extracts with omega-7 can accelerate wound closure, improve blood flow, and minimize scarring in wounded sheep. Further studies and industry collaboration may develop health applications.