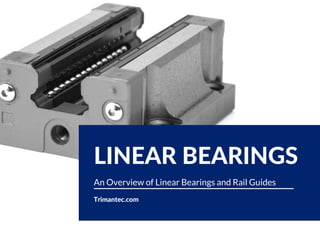

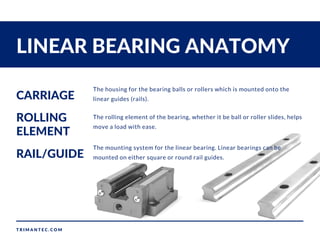

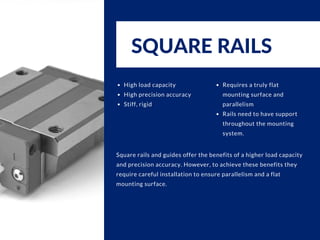

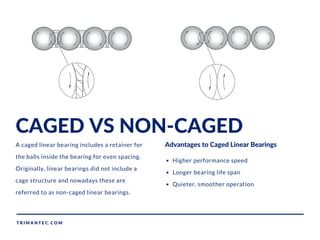

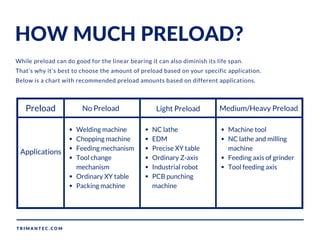

The document provides an overview of linear bearings and rail guides, detailing their historical context, anatomy, and options for mounting on square or round rails. It highlights the differences in load capacity, precision, and installation requirements of square versus round rails, and discusses caged versus non-caged linear bearings, including their performance benefits. Additionally, it explains the importance of preload for optimal bearing function and offers guidance on selecting preload amounts based on specific applications.