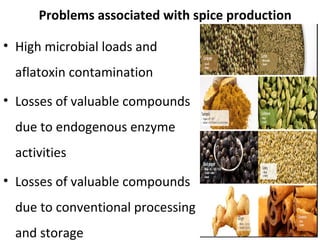

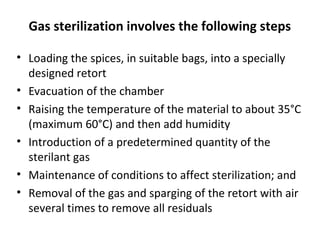

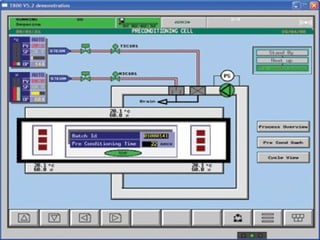

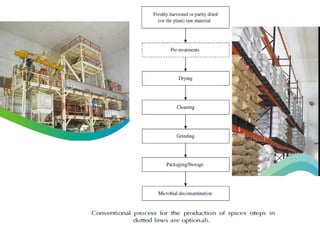

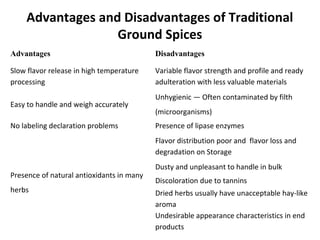

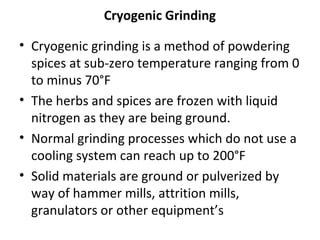

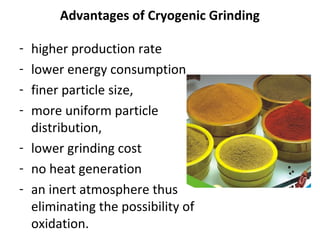

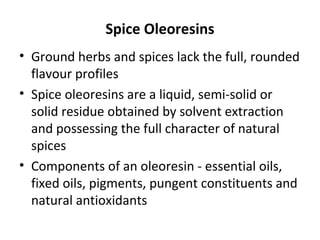

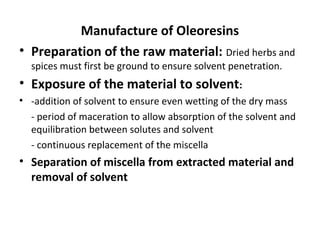

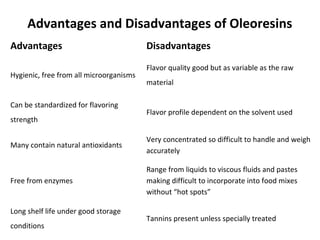

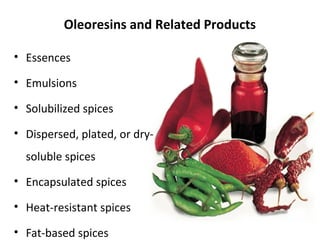

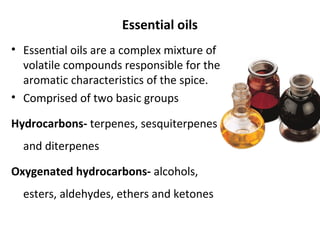

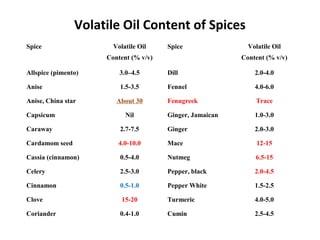

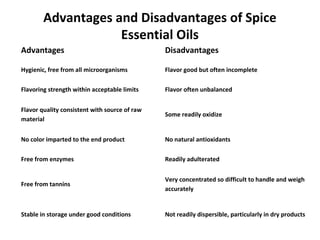

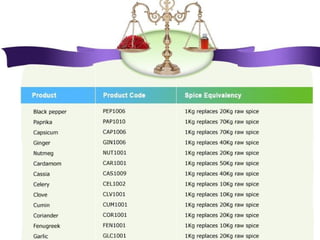

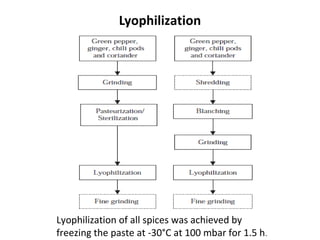

This document discusses advances in spice processing technologies in India. It provides an overview of India's dominance in spice production and trade globally. It then discusses various processing techniques for spices including sterilization methods like fumigation with ethylene oxide, irradiation, steam treatments and high hydrostatic pressure to reduce microbial loads. It also discusses grinding and milling of spices, production of spice oleoresins and essential oils, and applications of processed spices in culinary products and seasonings. Both advantages and disadvantages of different processing methods are highlighted.