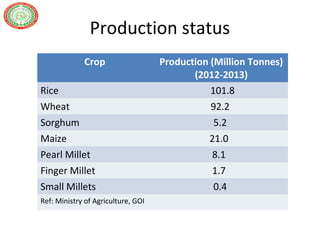

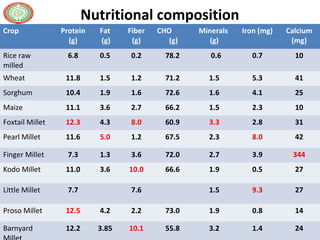

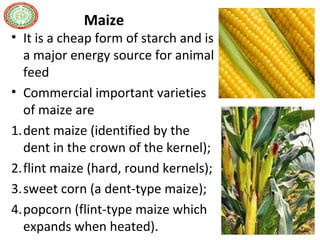

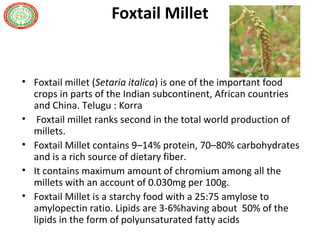

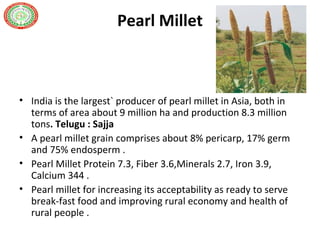

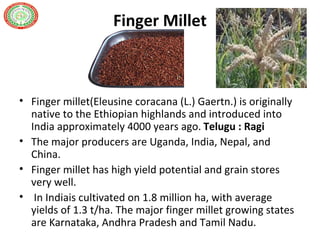

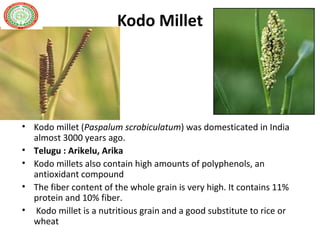

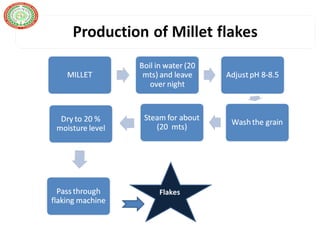

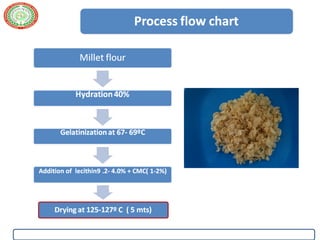

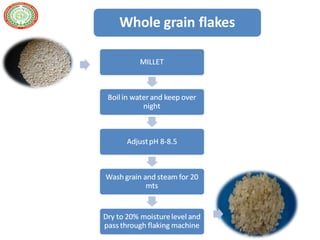

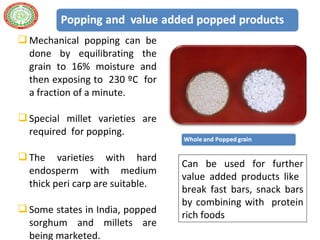

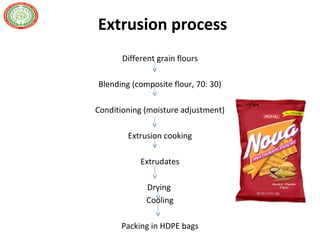

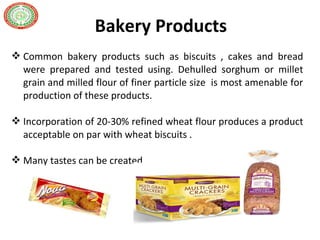

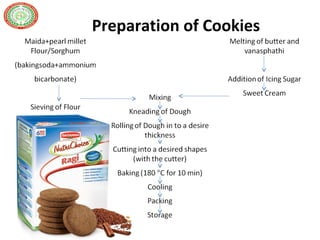

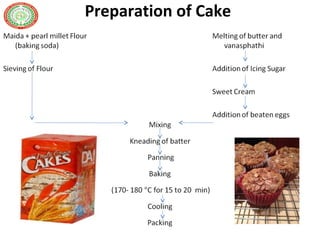

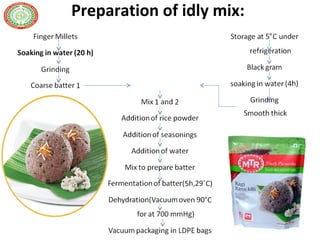

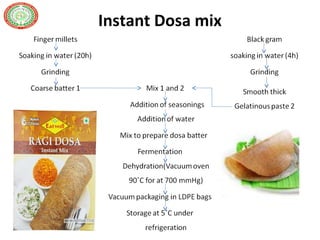

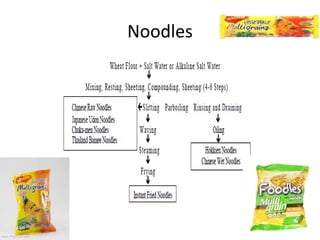

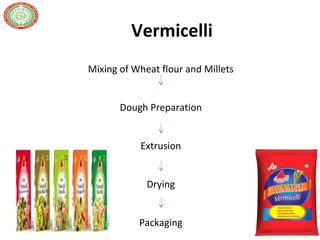

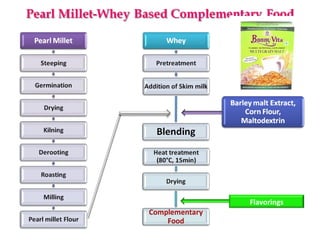

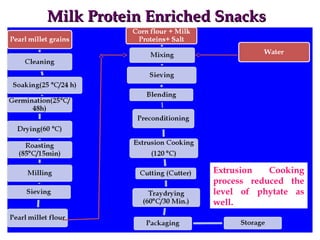

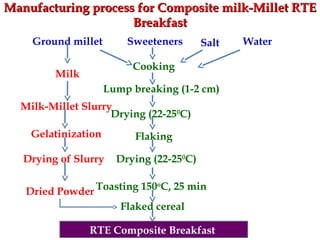

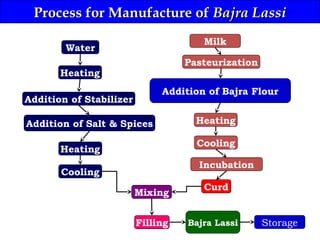

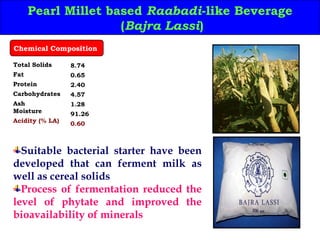

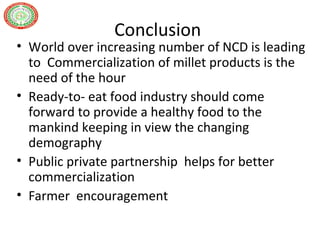

This document provides information on processing of cereals and millets. It discusses various cereals and millets commonly consumed in India including their nutritional composition. It then describes various processing techniques for cereals like milling, flaking and extrusion. Specific processing methods for crops like maize, sorghum, foxtail millet, pearl millet and finger millet are outlined. The document also discusses potential value-added products that can be developed from millets including snacks, baked goods, pastas and beverages. Manufacturing processes for selected millet-based products are described.