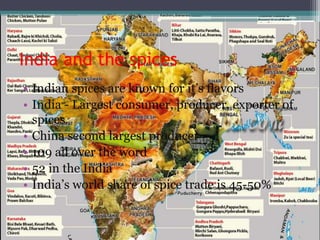

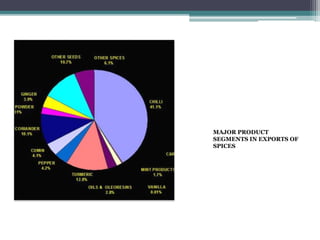

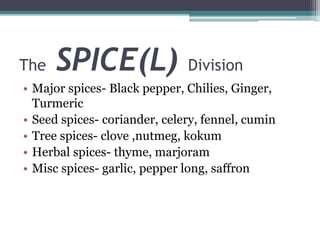

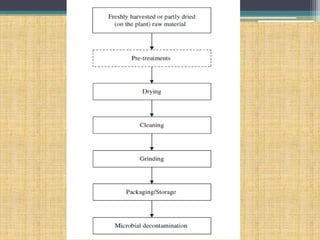

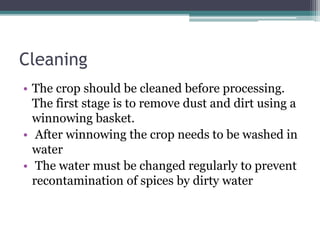

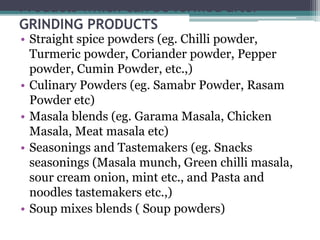

This document discusses spice production and processing. It begins with an introduction to spices, their history of use, and major producing regions. It then describes the major divisions of spices and pre-processing steps like cleaning, drying, and grading. Technological aspects of grinding and sterilization methods like ethylene oxide fumigation, irradiation, steam treatment and high pressure processing are explained. Spice oleoresins and conclusions on ensuring food safety through innovative processing are also covered. The document provides an overview of spice cultivation, production processes and technologies used to add value and ensure safety of spices.