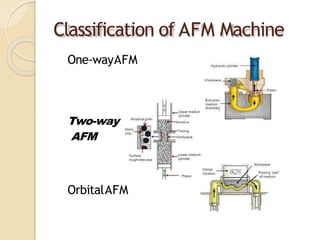

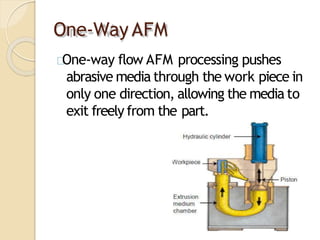

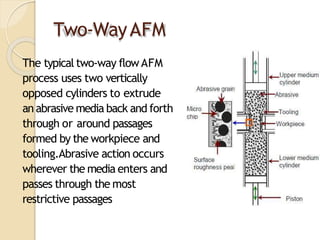

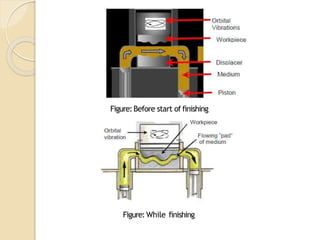

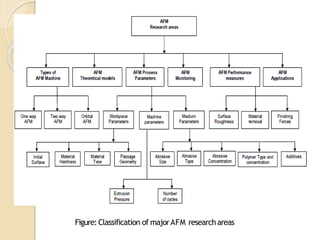

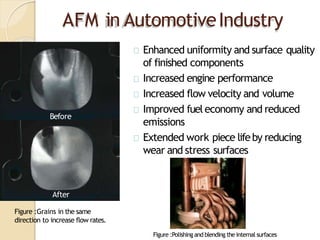

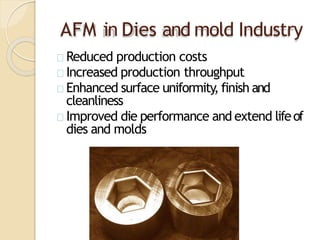

Abrasive flow machining (AFM) is a method developed in the 1960s to polish, deburr, and finish intricate internal surfaces and passages. There are three main types of AFM: one-way, two-way, and orbital. AFM uses an abrasive media that is extruded through the workpiece to remove material and produce a very smooth surface down to Ra of 50nm. Key advantages include simultaneously deburring, radiusing, and polishing, and producing uniform results. AFM is widely used in aerospace, automotive, medical, and mold industries to improve surfaces, reduce friction, eliminate imperfections, and extend component life. Research aims to further improve monitoring and control of