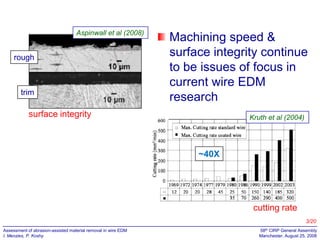

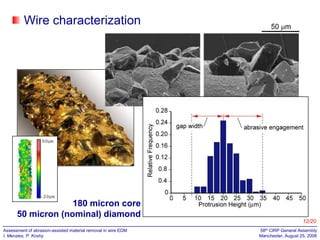

The document summarizes research into a hybrid wire electrical discharge machining (EDM) and grinding process called abrasion-assisted wire EDM. It presents experimental results showing that using a wire with embedded diamond abrasives can increase material removal rates by an order of magnitude compared to conventional wire EDM alone. The hybrid process also produces a machined surface with less recast layer damage. However, the abrasive wire degrades quickly. Further research is needed to develop more durable abrasive wires and implement the process on twin-wire EDM machines to improve machining of difficult materials like metal matrix composites.