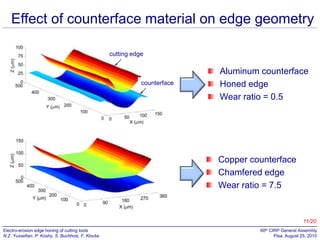

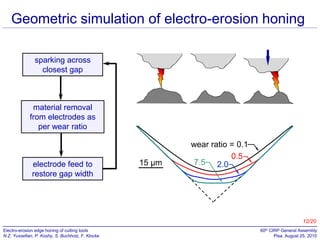

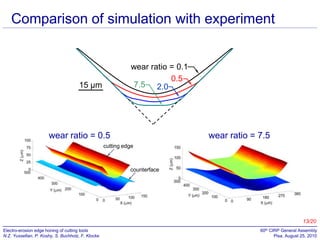

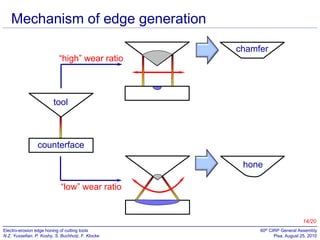

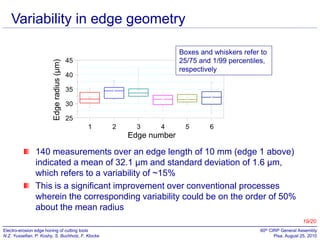

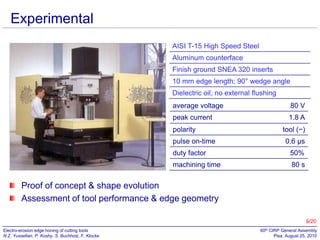

The document discusses electro-erosion edge honing as a method for preparing cutting tool edges. It finds that the counterface material used in electro-erosion honing critically influences the resulting edge geometry, with softer materials producing honed edges and harder materials producing chamfered edges. Experimental results show that electro-erosion honed cutting tool edges last significantly longer than conventionally ground edges when dry cutting steel. The process also achieves more consistent edge geometry between tools compared to conventional honing methods.

![Measurement of edge radius

NURBS model

point cloud data

circular regression

on profile data

150

Knot Points

Edge Cross Section

Fitted Circle

Y [m]

100

50

confocal microscope

0

10/20

Electro-erosion edge honing of cutting tools

N.Z. Yussefian, P. Koshy, S. Buchholz, F. Klocke

-50

100

150

200

250

60th CIRP General Assembly

300Pisa, August 25, 2010

350

400](https://image.slidesharecdn.com/cirp2010pisa-140302080404-phpapp02/85/Electro-Erosion-Edge-Honing-10-320.jpg)