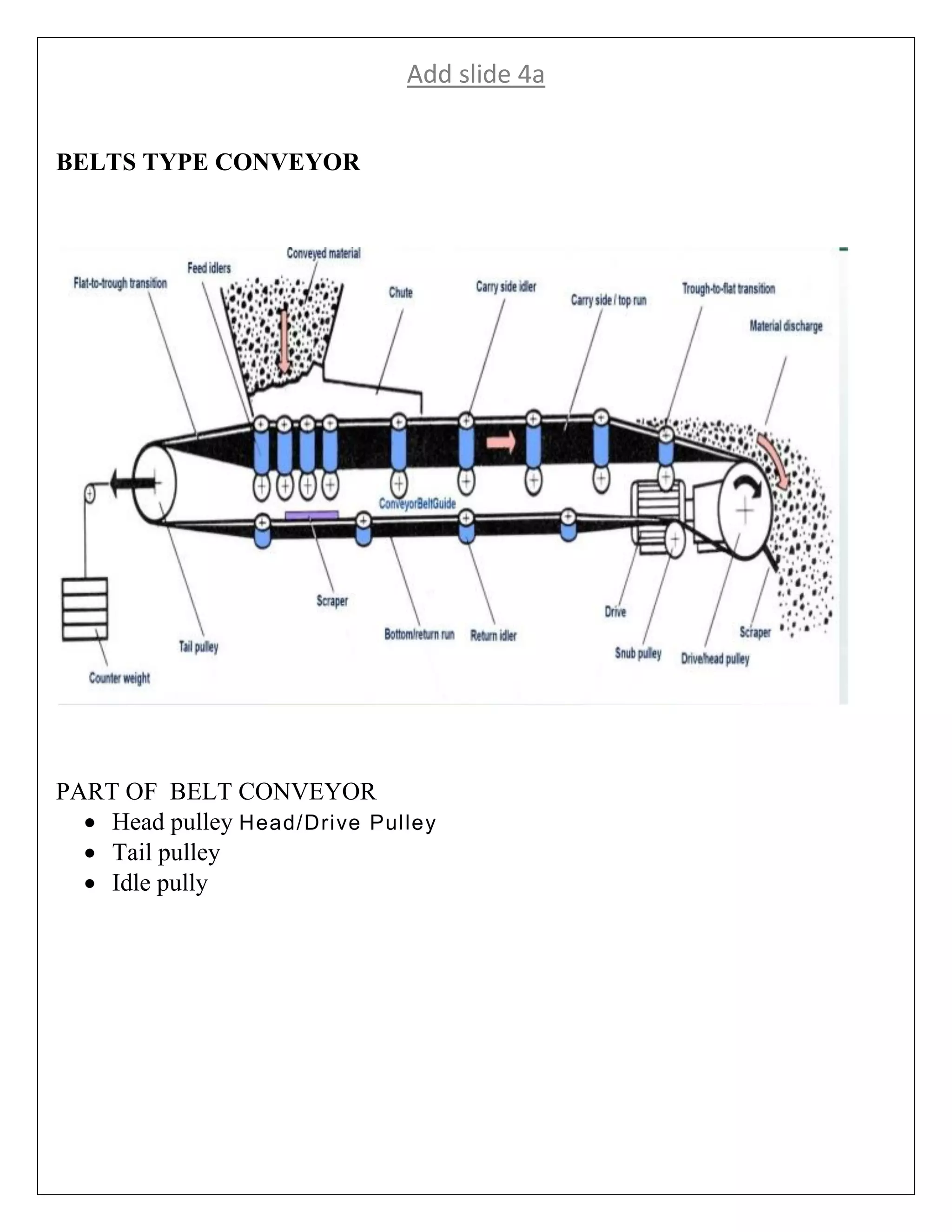

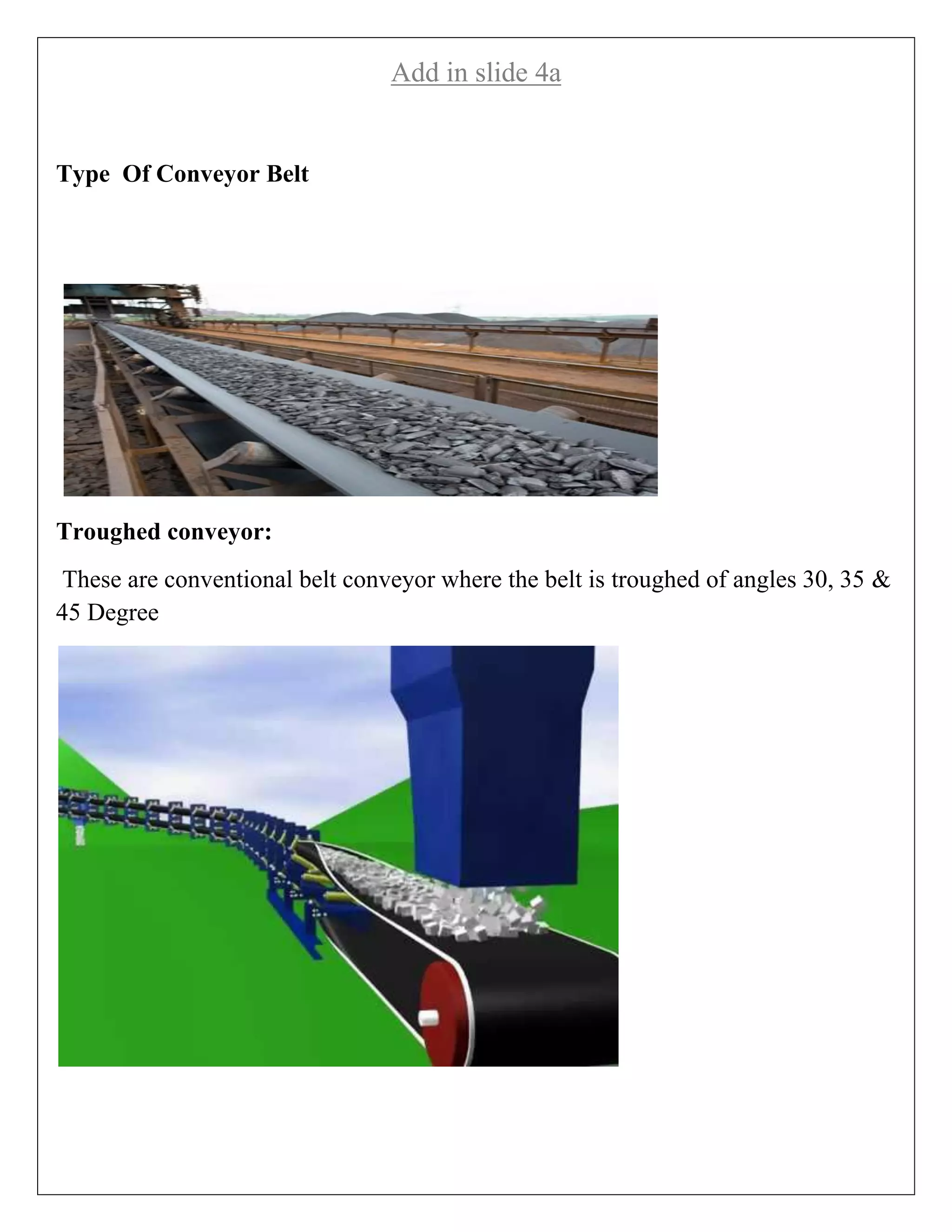

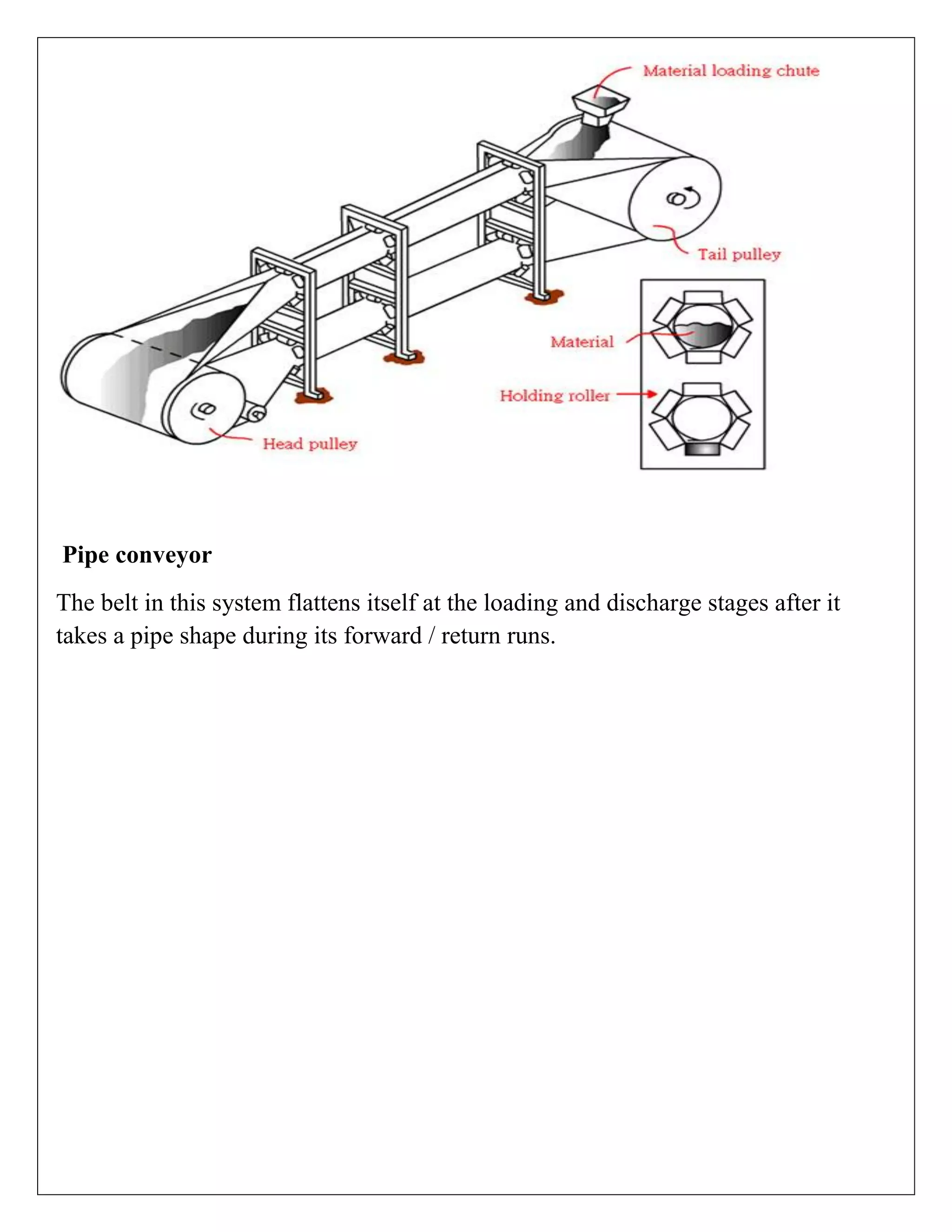

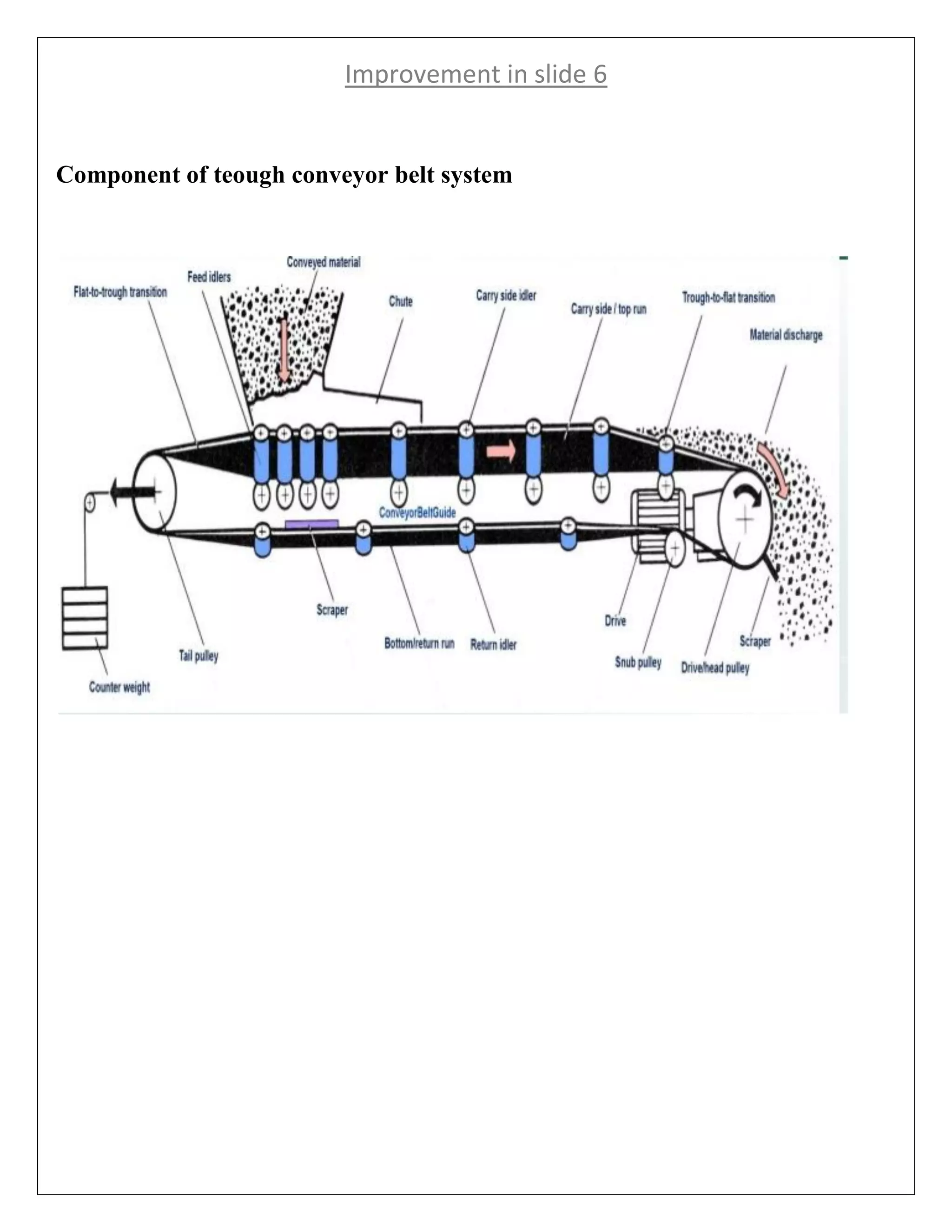

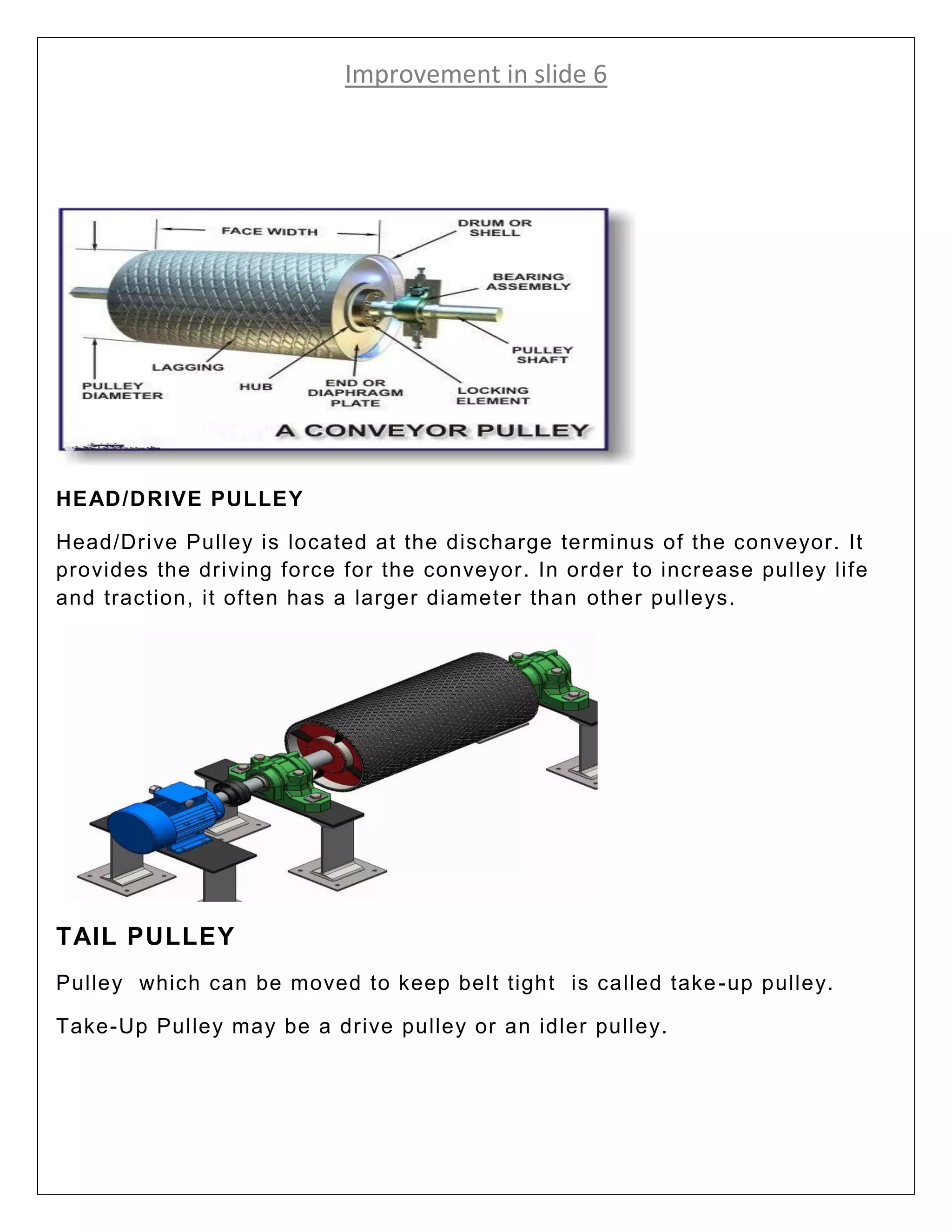

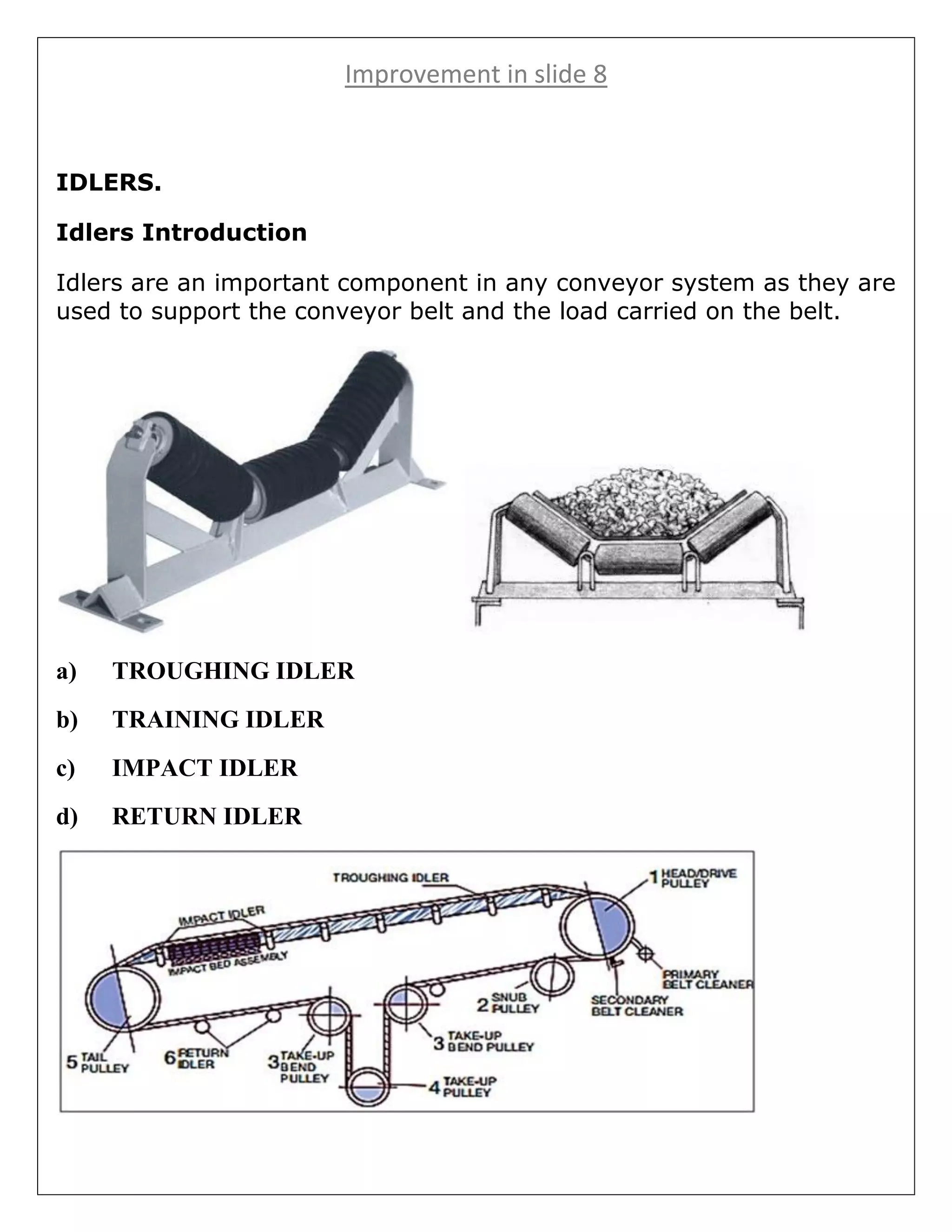

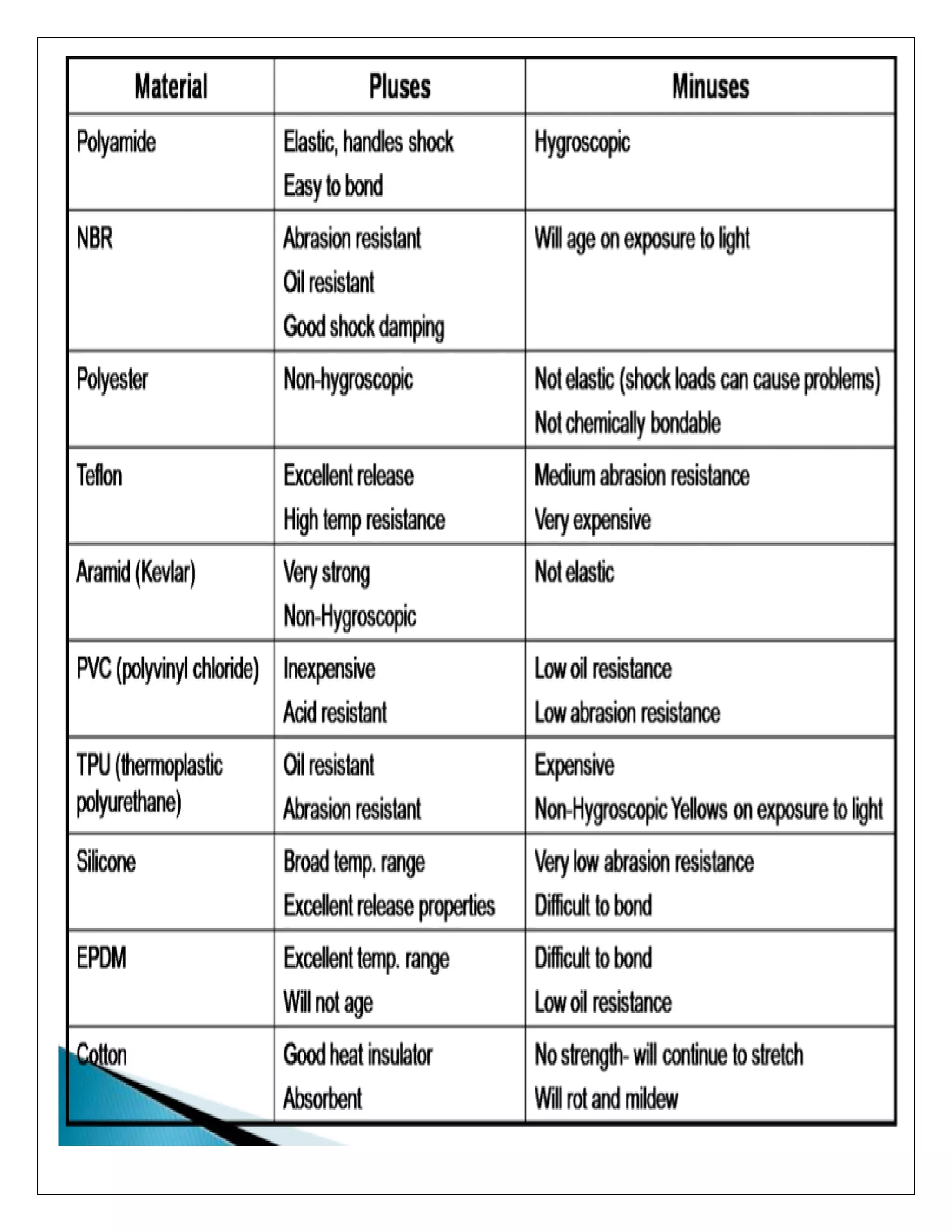

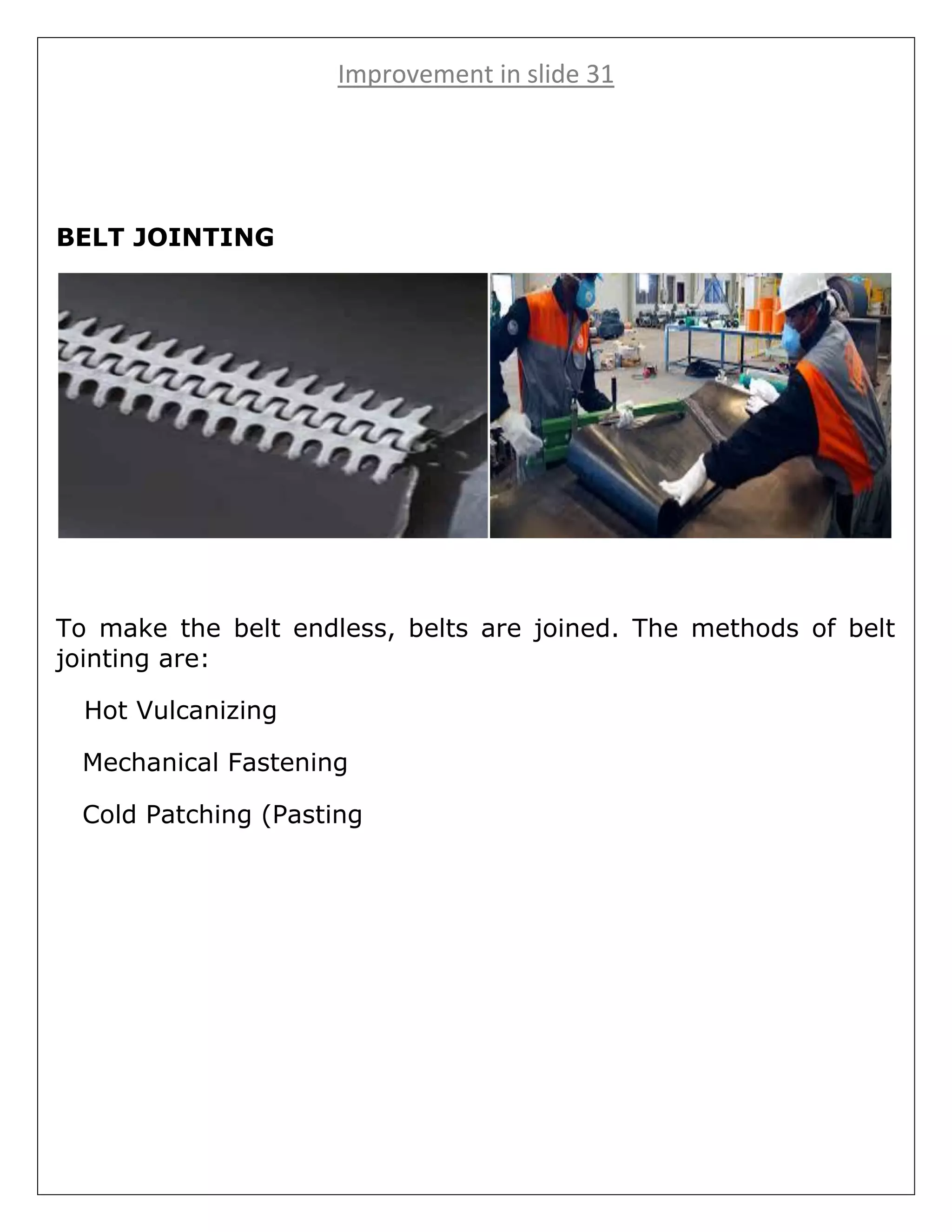

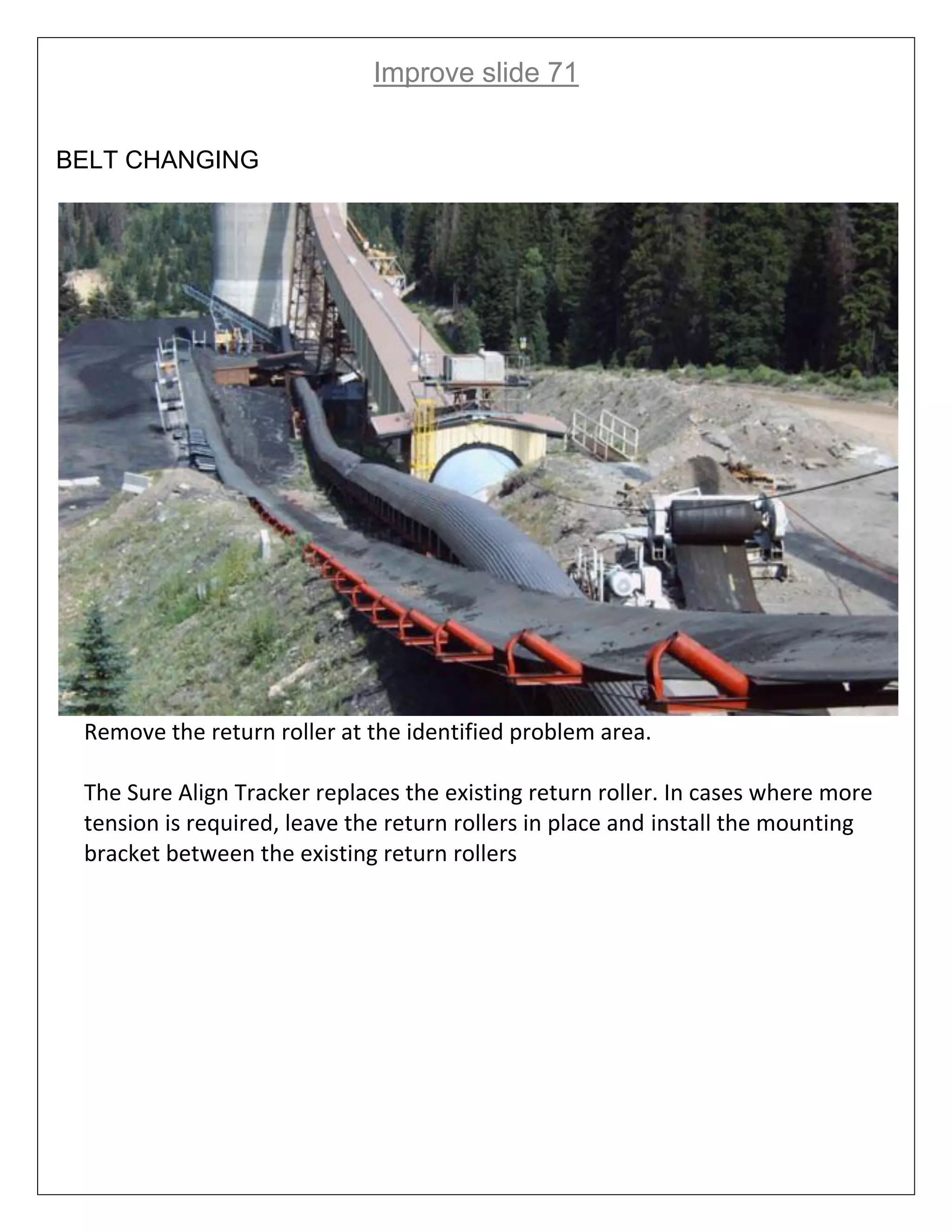

The document is an e-learning presentation on conveyor belt systems, detailing the types, components, and working principles of conveyors used for bulk material handling. It explains various conveyor types, essential parts like pulleys and idlers, and methods for maintaining and splicing conveyor belts. Additionally, the presentation covers safety devices and maintenance practices to ensure optimal performance and longevity of the conveyor systems.