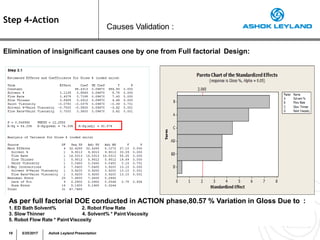

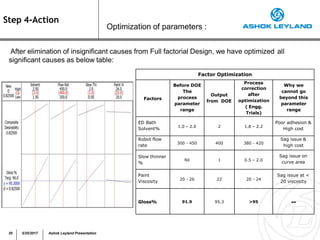

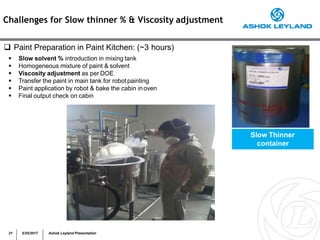

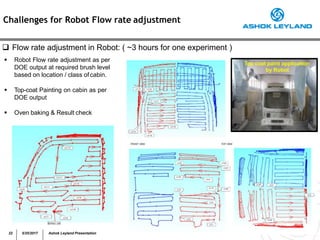

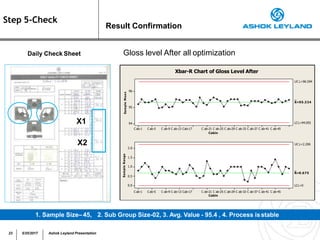

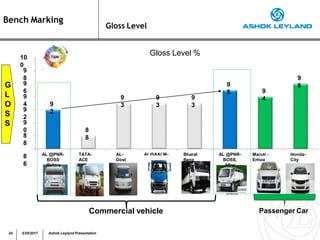

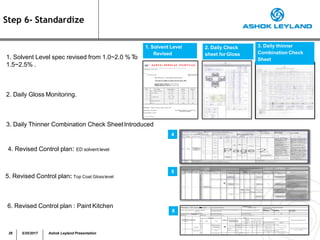

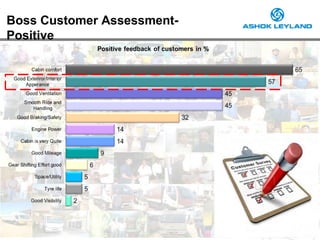

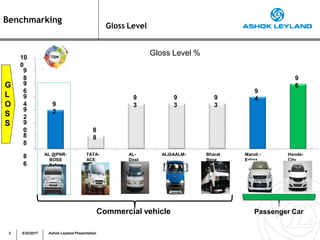

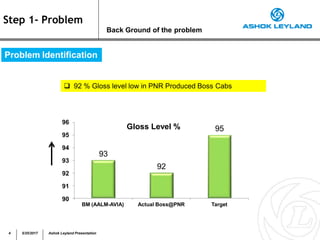

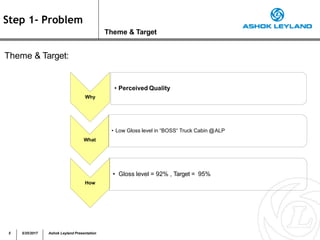

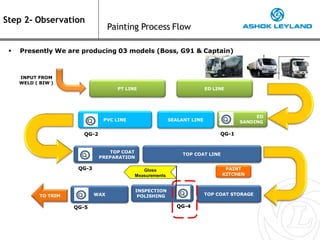

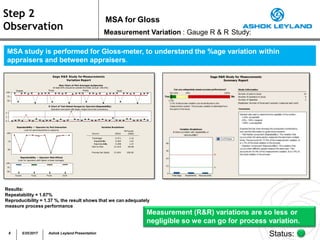

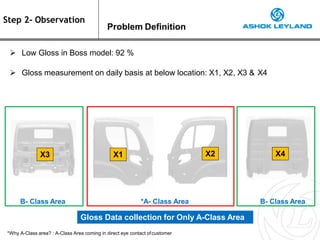

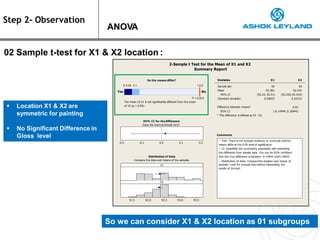

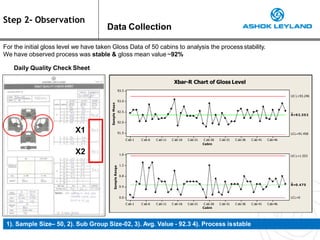

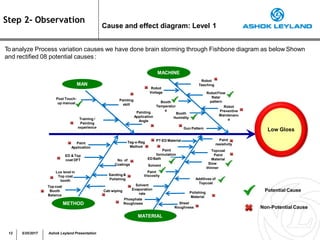

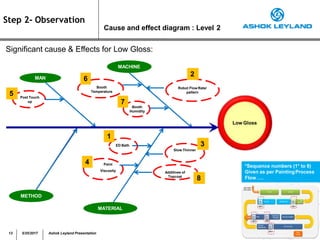

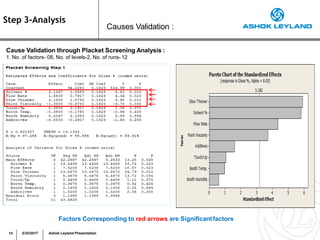

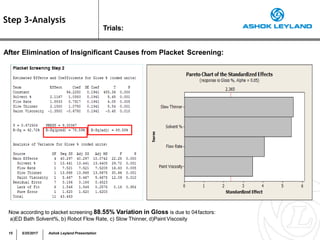

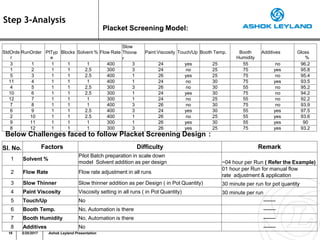

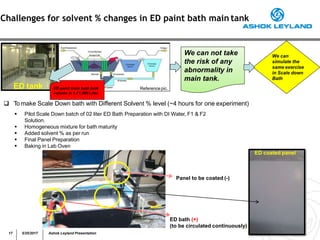

The document discusses improvements to increase the gloss level of paint on Ashok Leyland truck cabins. It begins with identifying low gloss levels of 92% on Boss model cabins as the problem. Potential causes of low gloss are analyzed using a fishbone diagram and screening analysis identifies ED bath solvent%, robot flow rate, slow thinner, and paint viscosity as significant factors. An experiment following a Placket design evaluates these factors at different levels. The most significant factors found through a full factorial experiment are further optimized to increase the gloss level above 95%, resolving the low gloss issue.

![Causes Validation :

Step 4-Action

These 04 factors taken up in a full factorialdesign to optimize the value of Gloss level:

No. of factors- 04 ,No. of levels-2, No. of runs- 32 [ N=(LF ) R ], Replicate=02

Factors Corresponding to red arrows are Significantfactors

18 5/25/2017 Ashok Leyland Presentation](https://image.slidesharecdn.com/glossbosscabpaint25-221125123732-b1d2edfe/85/Gloss-Boss-cab-Paint-25-08-16-pptx-18-320.jpg)