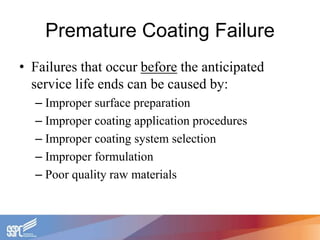

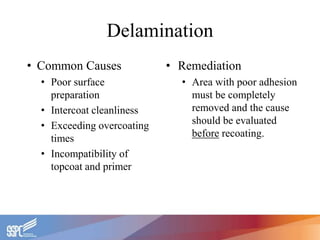

This document discusses coating defects, failures, and the role of coating inspectors. It describes common coating failures such as delamination, blistering, blush, sags/runs, and others. The coating inspector works to identify defects and prevent failures by ensuring proper surface preparation and application procedures. Premature coating failures can be costly due to substrate repair, rework, and downtime.