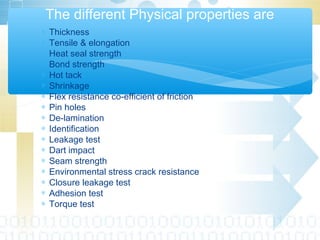

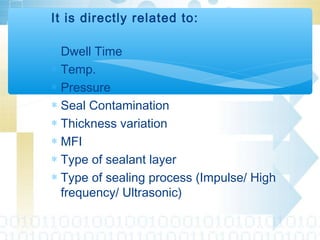

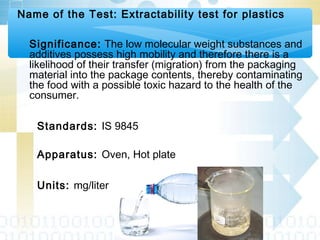

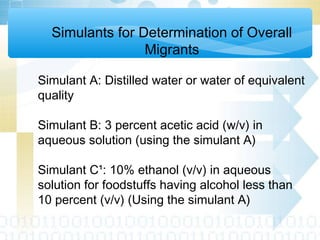

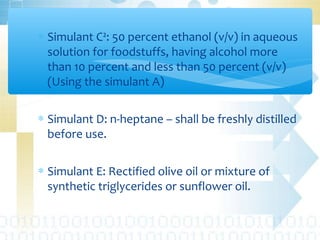

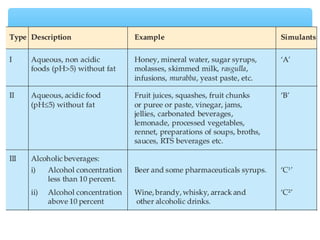

The document discusses various tests conducted on plastics used for packaging materials. It describes the three broad groups of tests - physical properties, physico-chemical properties, and optical properties. Several specific tests are outlined, including their significance, apparatus used, standards, and units of measurement. Key tests mentioned are haze, tensile strength and elongation, dart impact, heat seal strength, environmental stress crack resistance, and extractability.