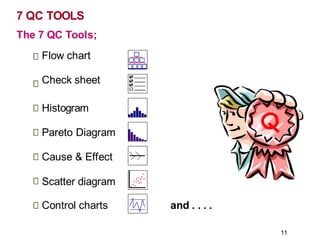

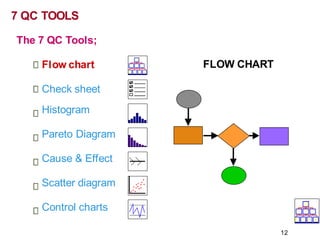

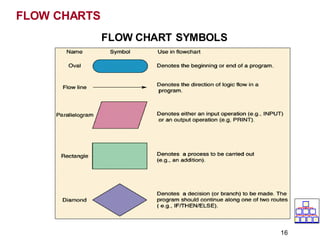

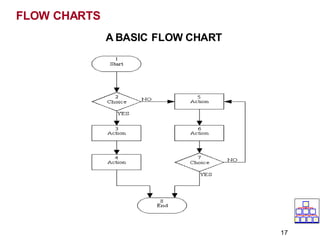

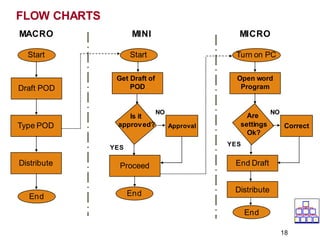

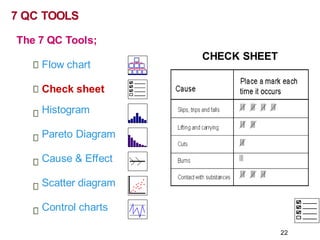

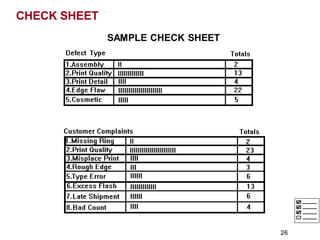

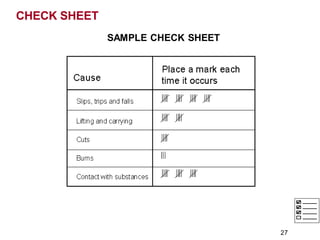

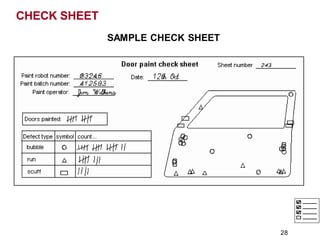

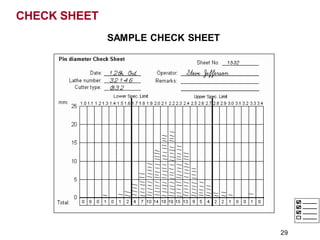

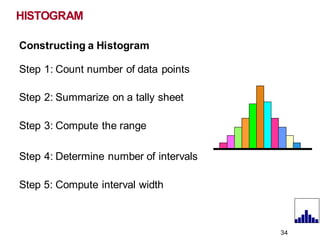

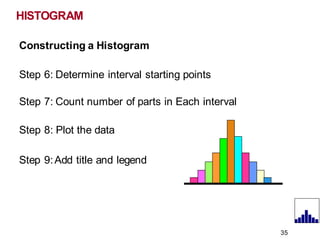

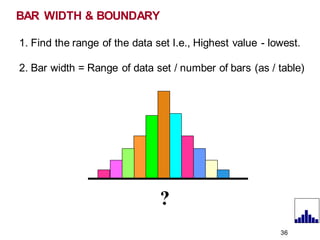

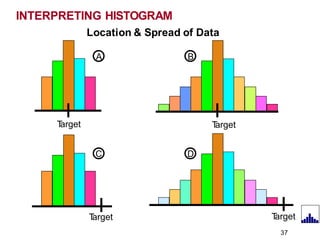

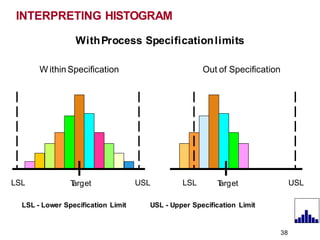

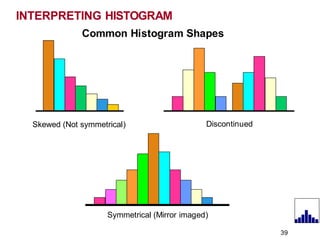

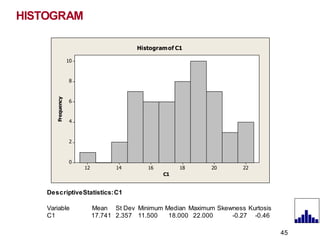

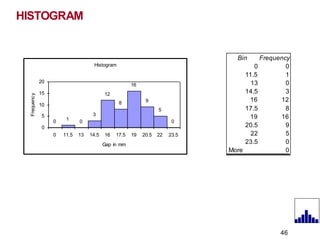

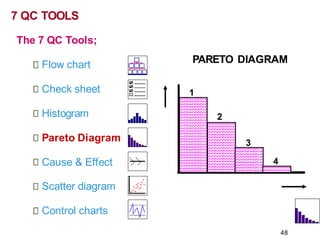

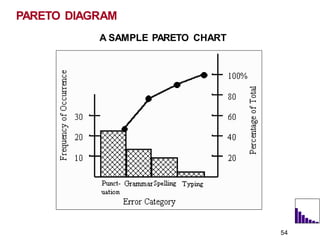

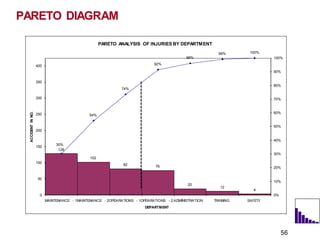

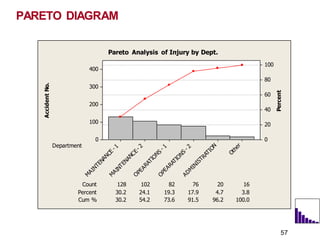

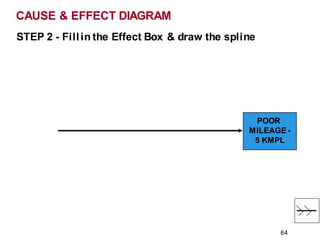

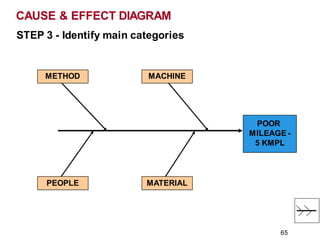

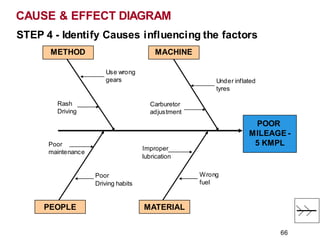

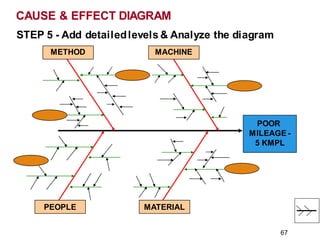

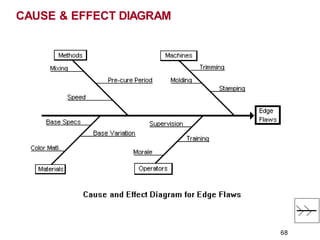

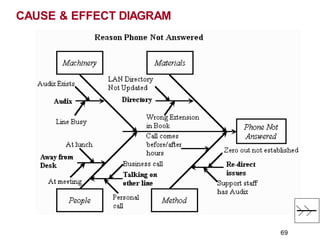

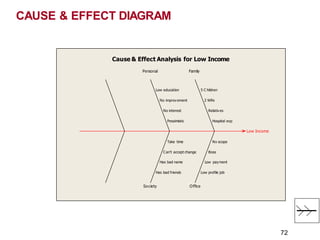

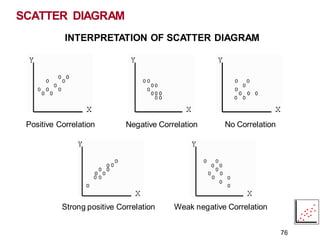

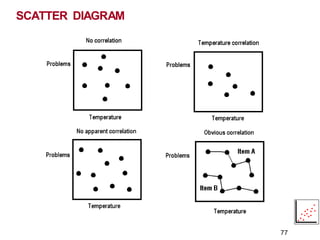

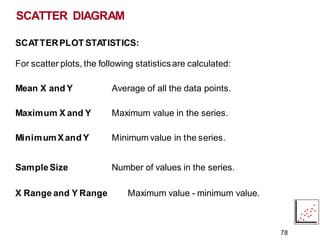

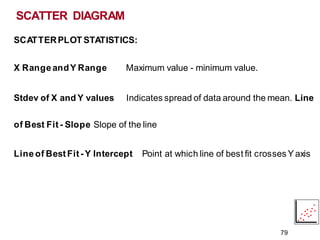

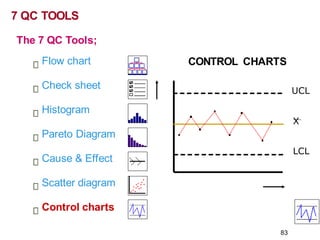

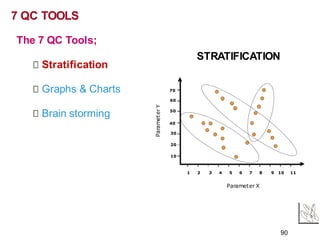

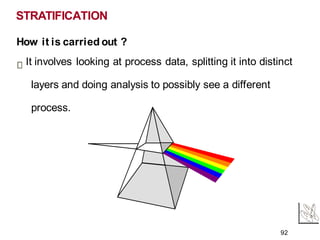

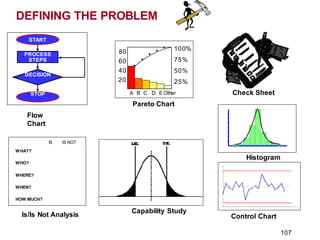

The document discusses various quality tools used for problem solving and continuous improvement. It begins by explaining why quality is important and introduces 7 fundamental quality tools - flow chart, check sheet, histogram, Pareto diagram, cause and effect diagram, scatter diagram, and control charts. For each tool, it provides a definition, discusses when and how to use the tool, and the benefits. It emphasizes that these 7 tools can solve 95% of quality problems in a factory. The document then dives deeper into each individual tool, providing examples and steps for constructing and interpreting the different charts.

![T o t a l

A 1 3 1 1 6

B 3 4 4 2 1 3

C 2 1 3 3 9

D 4 2 2 4 1 2

N G T

Brainstorming

EFFEC

T

Cause Cause

Cause Cause

Cause

P r o ble m

S ta te m e nt

O perational

D efinitions

Define the Team

Team Members

Name Role

John Team Leader

Mary Coach

Bob Teacher

Susan Custodian

Bill Secretary

Jane Driver

Wayne Student

P u r p o se & Vi si o n

_ _ _ _ _ _ _ _ _ _ _ _ __ _ _ __ _ _ __ _ __

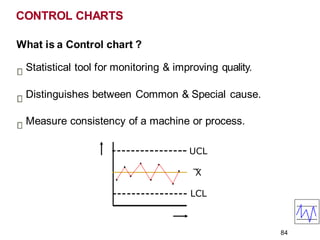

Lower Control Limit [LCL]

CONTROL CHART

_ _ _ _ _ _ _ _ _ _

U

_

p_

p

_

er_

C

_

on_

t_

ro

_

l L

_

i

m

__

i

t_

[U

_

C

_

L

]_

Average

Time

Measurement

Average

RUN CHART

Time

Measuremen

t

Rest ra in

Fo

D riving

Fo r ces

FO RC E FI E LD ANALY SI S

INTERRELATIONSHIP

Cause

Cause Cause

Cause

Cause

Cause

C HECKLIST

Date Total

Category 1 Data Data

Category 2 Data Data

Category 3 Data Data

Category 4 Data Data

D ec is ion

Proc es s

St ep

St op

St art

FLOWCH

ART

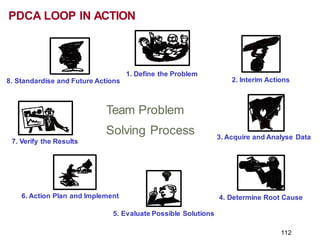

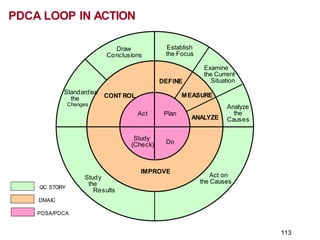

The Plan-Do-Study-Act [PDSA] Cycle

Plan

Do

Act

Study

Delighted

Customers

Systems Progress Pilot Project Five Whys?

Why?

Why? Why?

Why?

Why?

BAR CHART

Category

Survey Results In Percent

COLUMN CHA RT

Number

SURVEY

1.xxxxxxxxxx

2.xxxxxxxxxx

3.xxxxxxxxxx

Project Bulletin Board

RED ITEMS REQUIRE ACTION WITHIN 30 DAYS.

1.

2.

3.

1.

2.

3.

YELLOW ITEMS ARE SCHEDULED TO MOVE INTO RED.

1.

2.

3.

GREEN ITEMS CAPTURE ALL IMPROVEM

ENT S

UGGESTIONS.

Completed Items move to the

Succes s ful Projects Board.

Items mus t be organized into s egments

capable of being addres s ed within 30 days .

Items move into yellow as space permits.

0

1

2

3

CORRELATION CHART

Factor

1

No Correlation

100 %

90 %

80 %

70 %

ETC.

Consensogram

Pie Chart

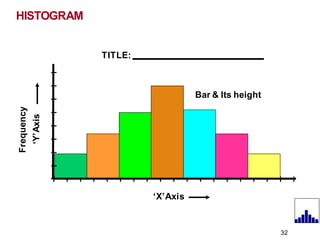

Frequency

HIST OGRAM

Time

M

easurement

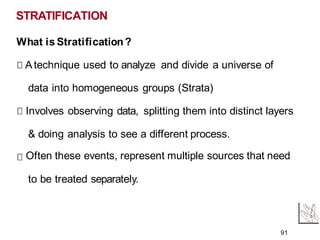

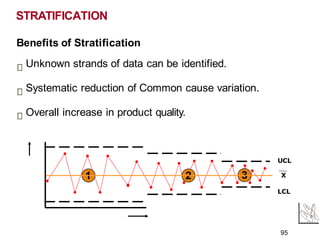

A Alone

B Alone

Stratification

A and B Combined

Imagineer ing

Flow T ree

Knowledge

Understanding

Application

Analysis

Capacity Matrix

Aim or Capacity Breakdown

Res ult

Parking

Lot

+

What is go

ingw

ell

?

.

What needs im

p

rov

em

e

n

t

? I/O

What ques t

iondoy

ouha

ve

? W

ha

t aretheissues o

r ob

s e

rv

atio

ns.

A ffinity Diagram

PR

OJECT

STEPS

1.

2.

3.

4.

5.

Time

GannttChart

Present Org

an

izatio

n

1.

2.

3.

4.

Future Org

an

izati

o

n

1.

2.

3.

4.

Positiv eFo

rces T

hatCreat

e G

rowth

1.

2.

3.

4.

5.

6.

+

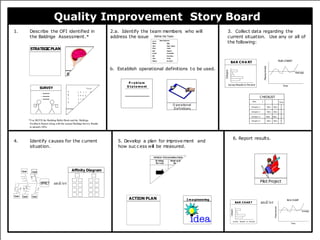

Quality Improvemen t Story Board

b. Establ i shoperat

i on

al defi

ni

ti

onsto b

e used.

1. D escr

i b

e the O

FIi

denti

fi

edi nthe 2.

a. Ident

i f

y t

he t

eamm

em

bersw

ho w

i

l l 3.Col l

ectdat

a r

egardi

Bal dri ge Assess

ment

. address the i ss

ue. current si t

uati

on.

5. D

eve

how

4. Identi fycausesf

orthecurr

ent

si tuati on.

ACTION PLAN

STRATEGICPLAN

A Quality Tool Belt](https://image.slidesharecdn.com/7qctoolsforproblemsolvingpresentation-221223003046-75bd2006/85/7-QC-Tools-For-Problem-Solving-Presentation-pdf-108-320.jpg)