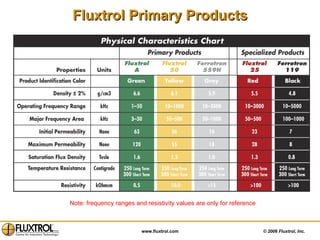

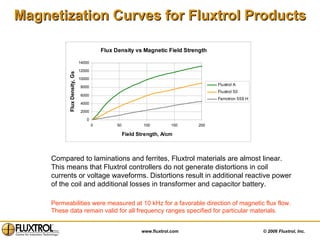

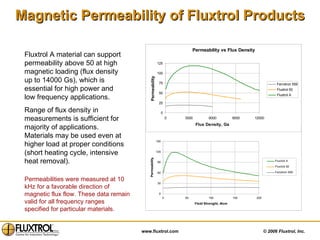

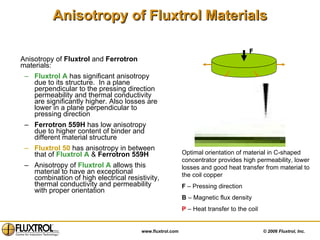

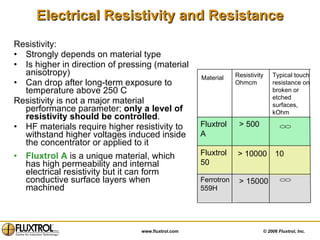

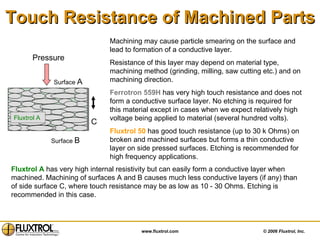

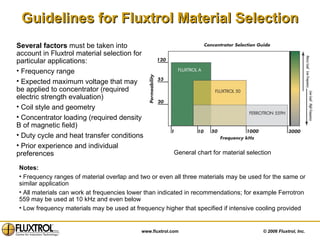

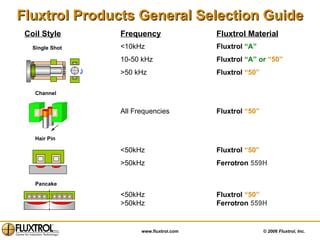

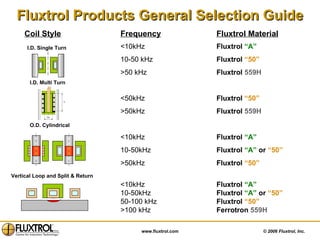

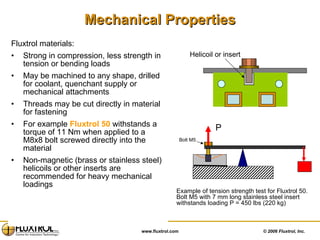

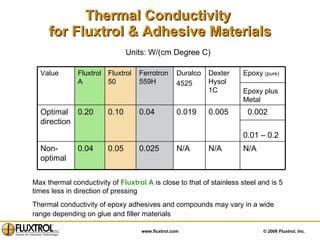

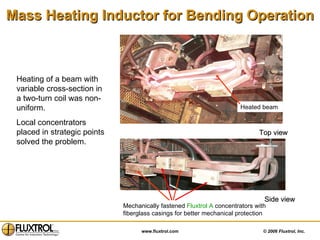

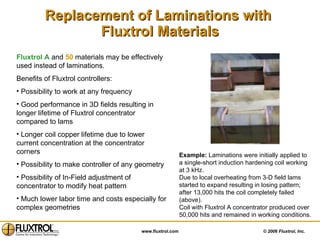

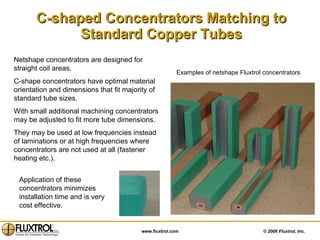

Fluxtrol Inc. manufactures magnetodielectric materials, primarily for induction heating applications, including several standard and custom materials such as Fluxtrol A and Ferrotron 559H. These materials are known for their excellent machinability, mechanical strength, and heat resistance, making them suitable for various induction heating coils and related applications. The document discusses material properties, selection guidelines, manufacturing techniques, and maintenance practices for maximizing the performance and lifespan of induction heating coils.