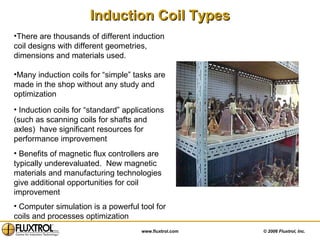

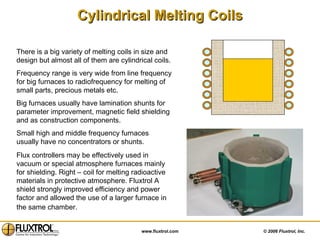

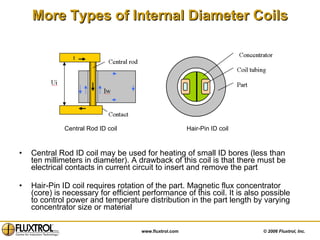

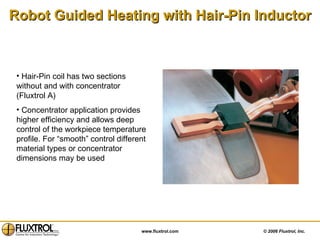

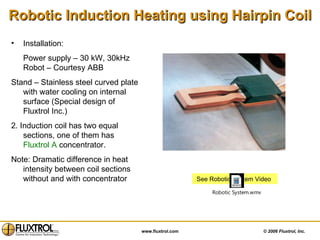

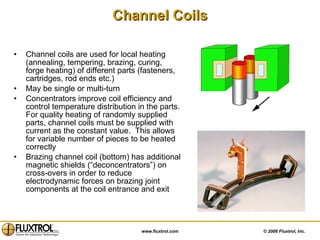

The document outlines the requirements and design considerations for induction coils used in various heating applications, emphasizing the importance of specifications, efficiency, and cost-effectiveness. It discusses advanced induction coil design techniques, including the use of magnetic flux controllers, computer simulations, and the evolution of coil types for different tasks. Various coil designs, such as cylindrical, multi-turn, and channel coils, are described, highlighting their specific applications and the benefits of optimization through modern materials and technologies.