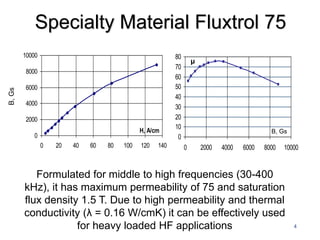

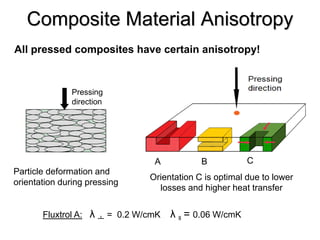

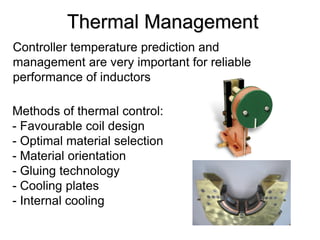

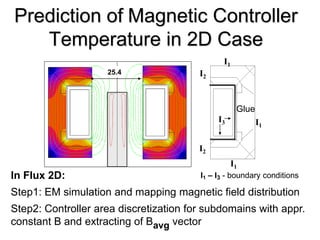

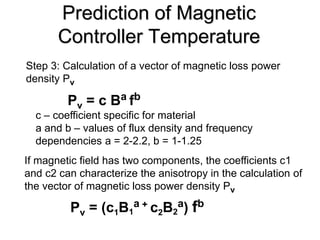

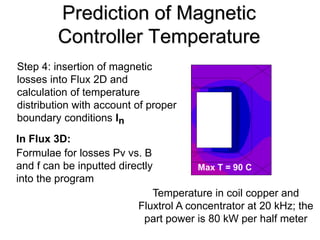

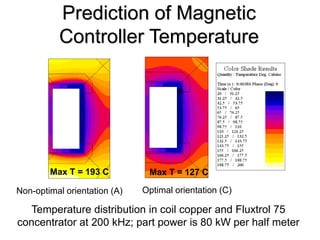

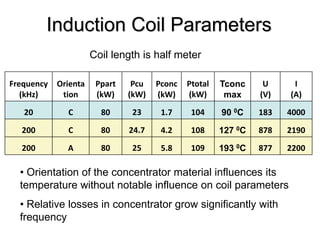

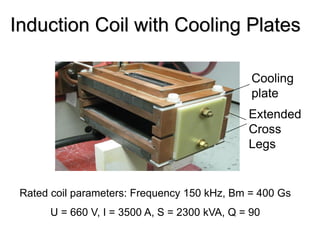

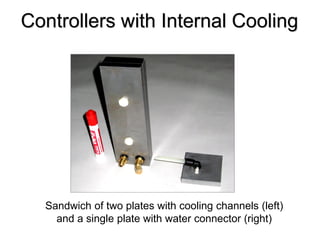

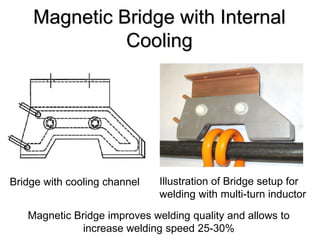

The document discusses the development and application of composite magnetic controllers for induction coils, particularly highlighting the new material Fluxtrol 75 which has enhanced thermal conductivity. It emphasizes the importance of temperature prediction and management in maintaining reliable inductor performance, detailing methods for thermal control. Additionally, the document presents simulation techniques for predicting temperature distribution and the benefits of internal cooling in preventing overheating.