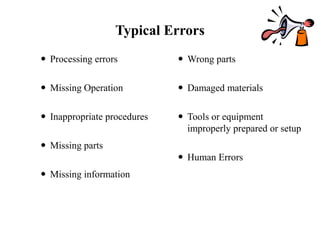

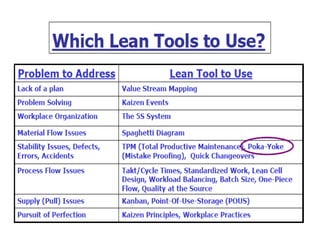

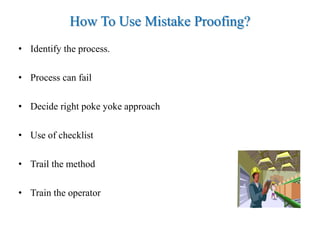

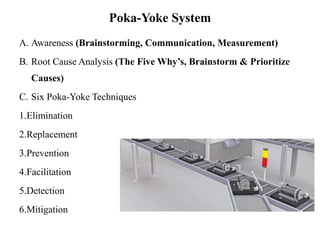

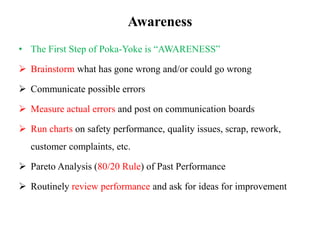

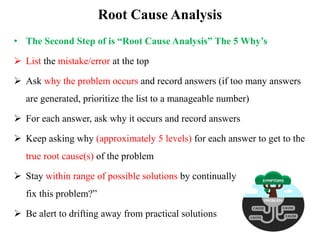

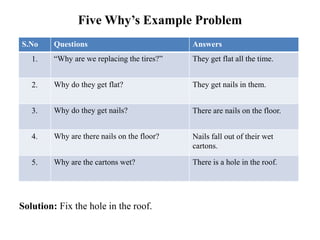

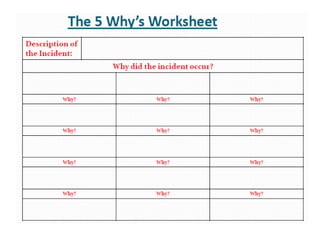

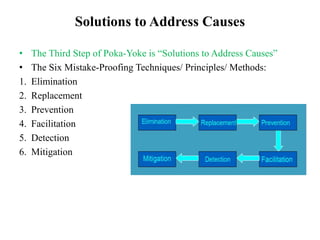

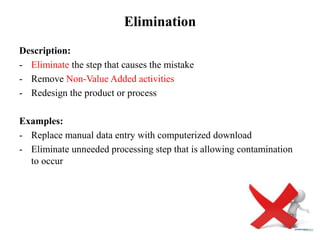

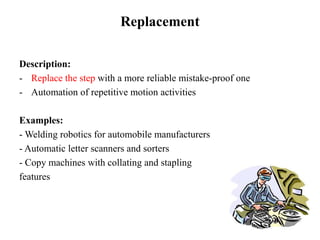

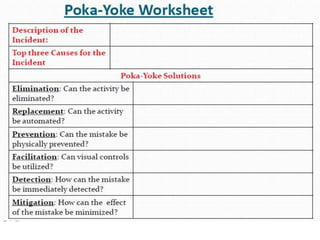

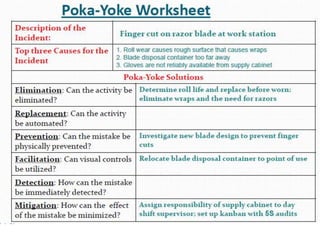

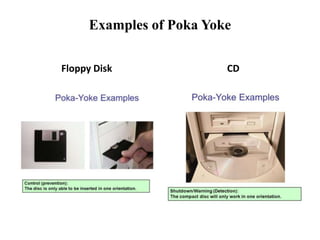

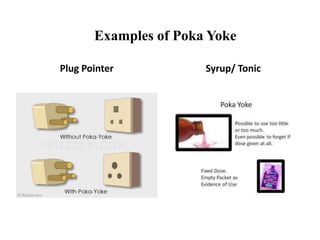

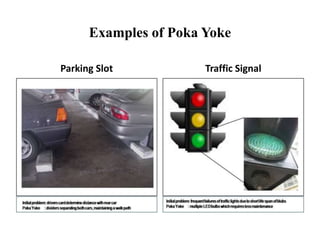

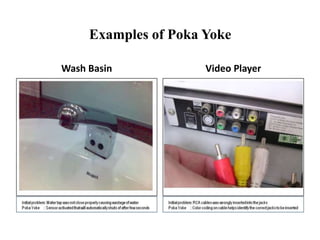

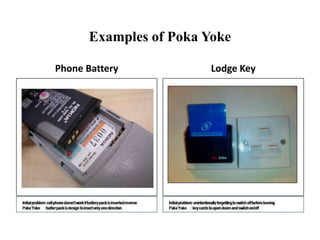

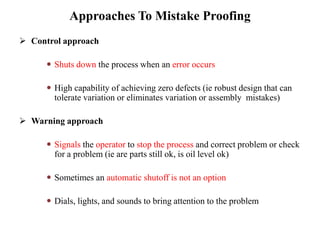

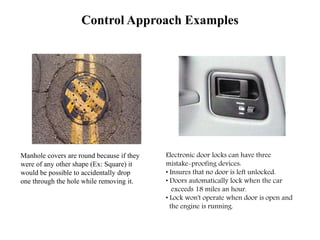

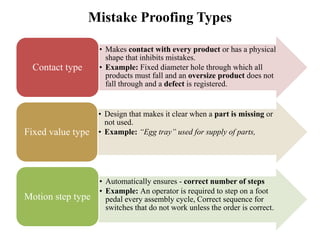

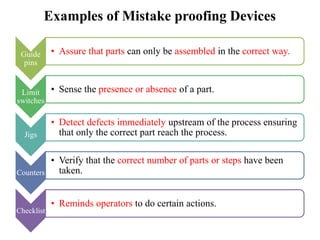

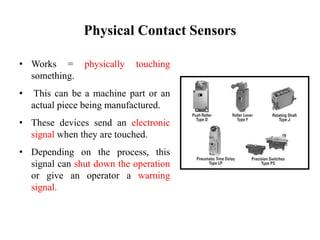

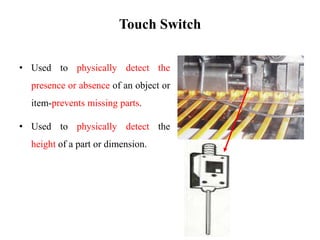

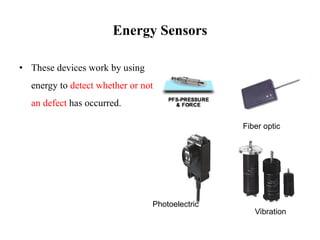

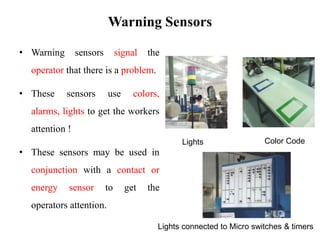

The document provides an overview of Poka Yoke, a quality assurance technique aimed at eliminating defects by preventing mistakes. It discusses typical errors, how to implement mistake proofing, examples of Poka Yoke systems using different techniques (e.g. controls, warnings). Sensing devices like physical contact sensors and energy sensors are described for detecting defects. The benefits of Poka Yoke include discovering and eliminating defects with little effort through consecutive verification and self-checking at each process step. The overall goal is to increase quality and customer satisfaction by reducing waste from defects and rework.