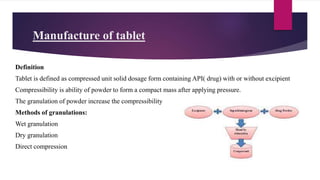

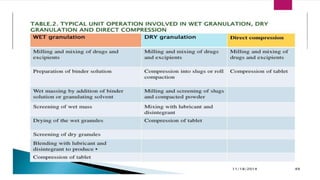

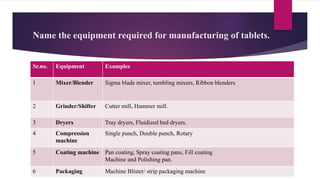

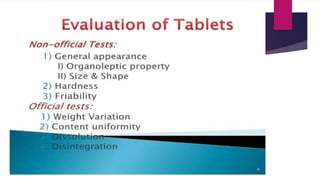

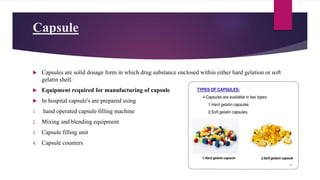

This document provides an overview of non-sterile manufacturing processes. It discusses the manufacture of tablets, capsules, liquid orals, and external preparations. The key requirements for the manufacturing area include controlled temperature, humidity, air filtration, cleaning and sanitization. Tablet manufacturing involves mixing, granulation, drying, compression and coating. Capsule manufacturing uses filling machines. Liquid oral production requires mixing tanks, filtration and bottling equipment. External preparations are made using mixing tanks, mills and filling equipment.