This document discusses corrective and preventive action (CAPA) basics, including:

- The purpose of CAPA is to identify and address quality problems and prevent recurrence.

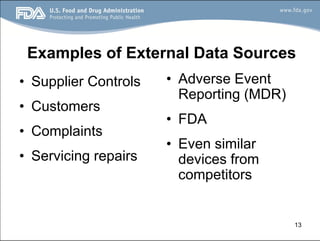

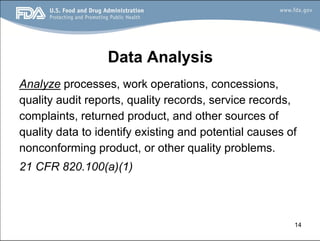

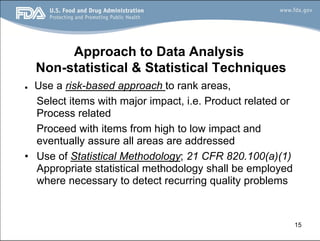

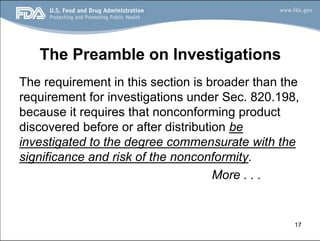

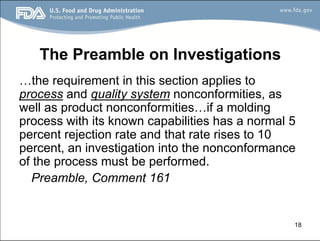

- Regulations require manufacturers to establish CAPA procedures, collect and analyze data, investigate issues, identify and validate corrective/preventive actions, and document activities.

- The level of CAPA should be appropriate to the risk level of the problem. Relevant information must be communicated and submitted for management review.