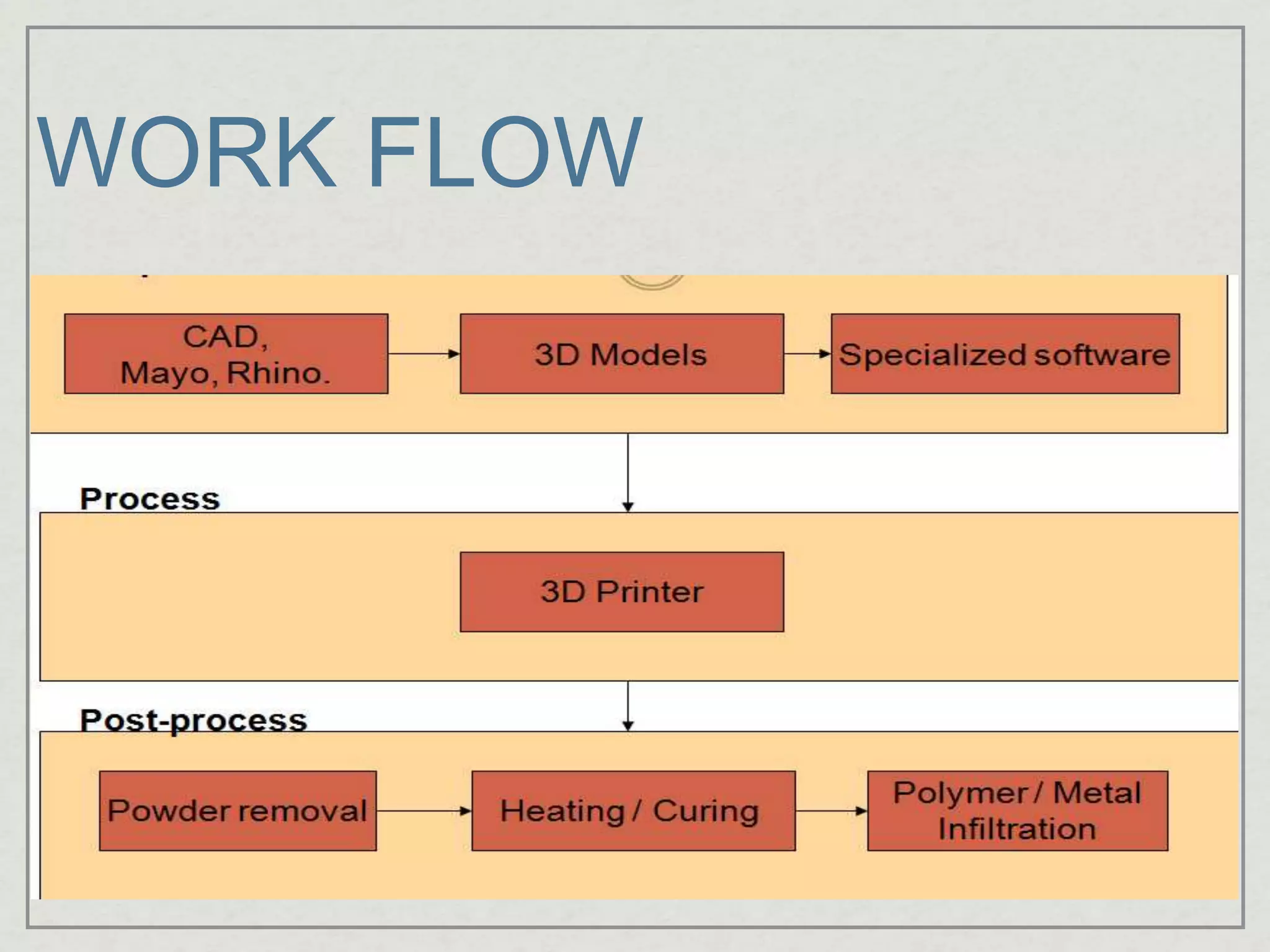

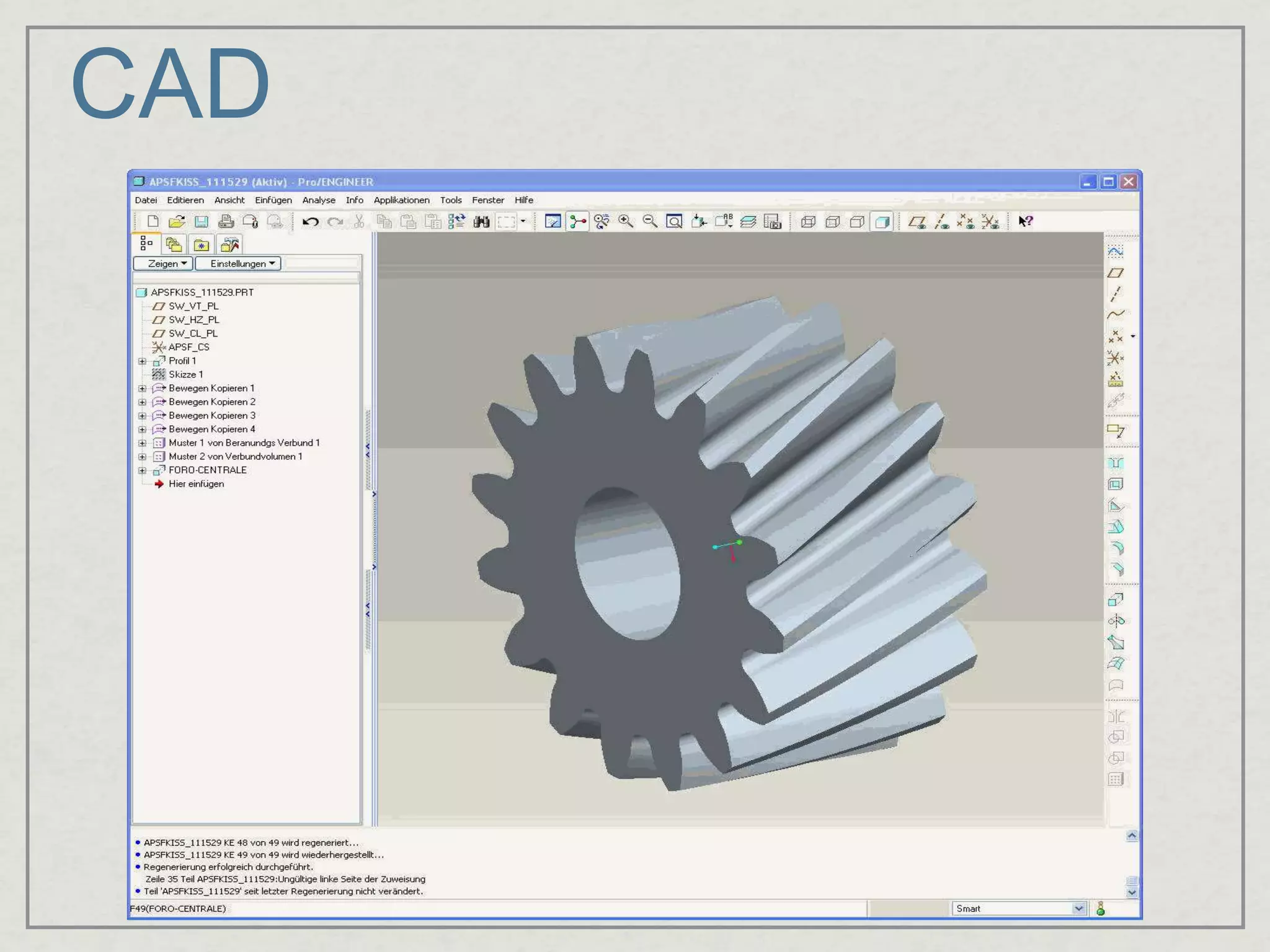

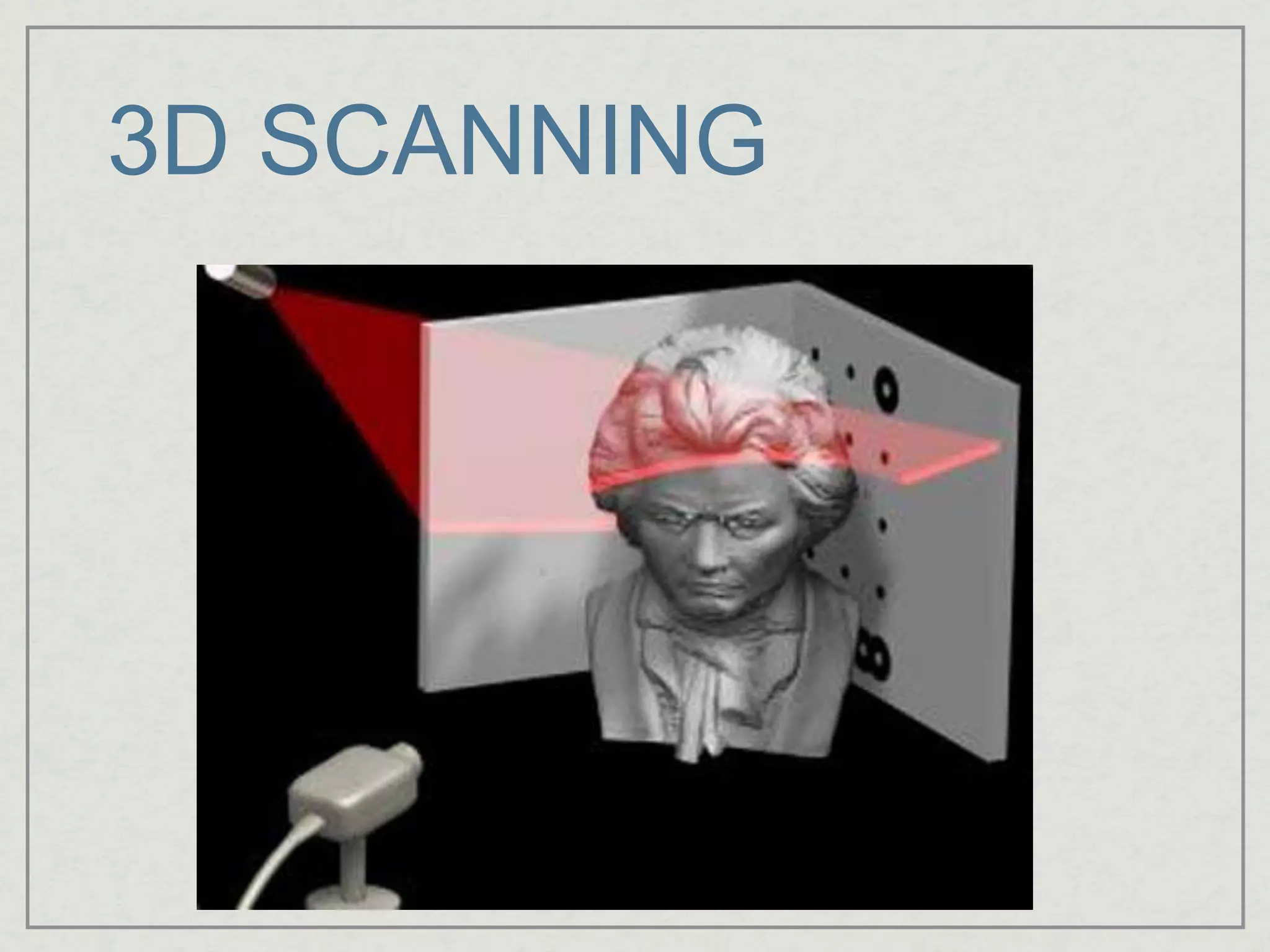

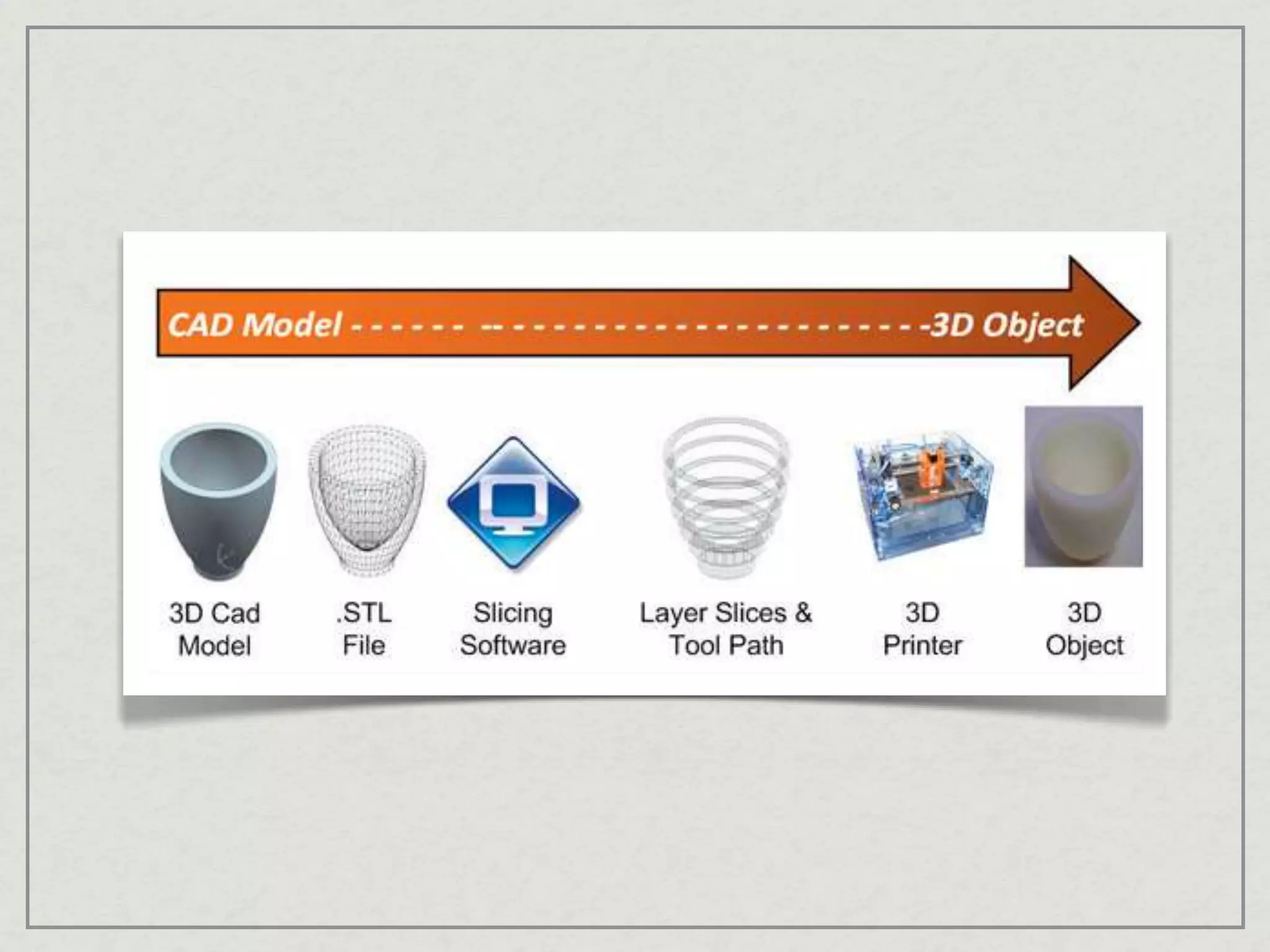

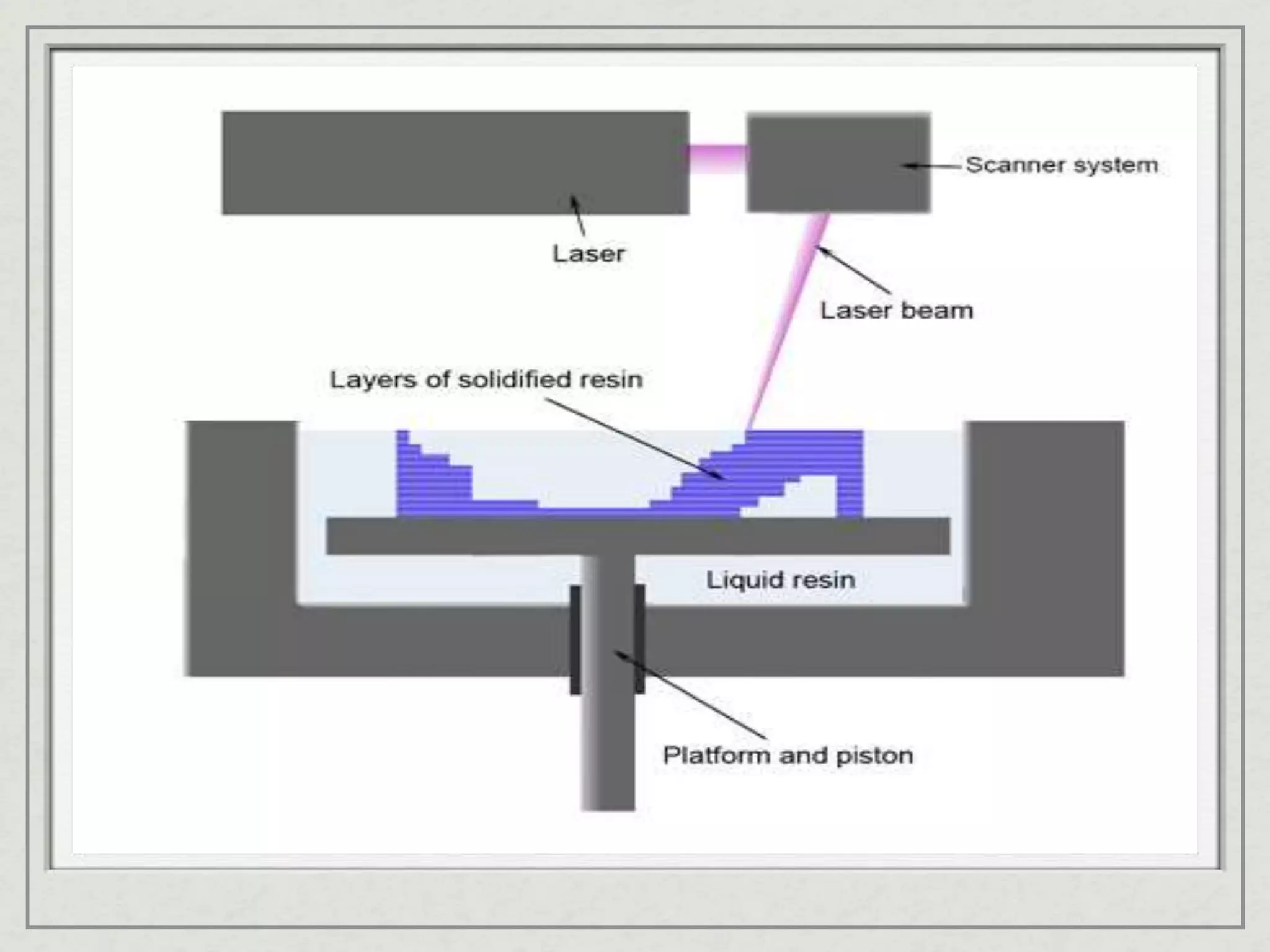

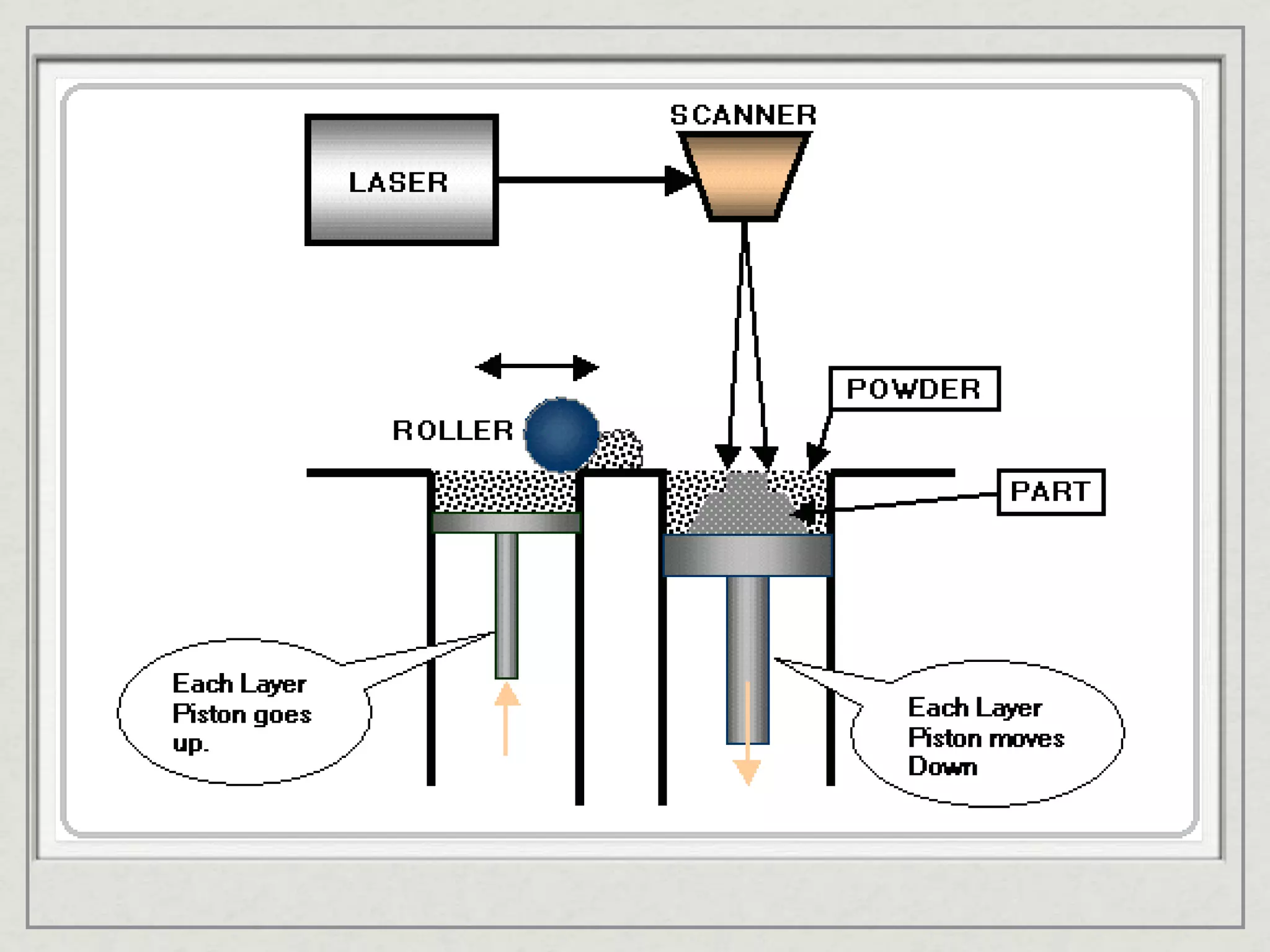

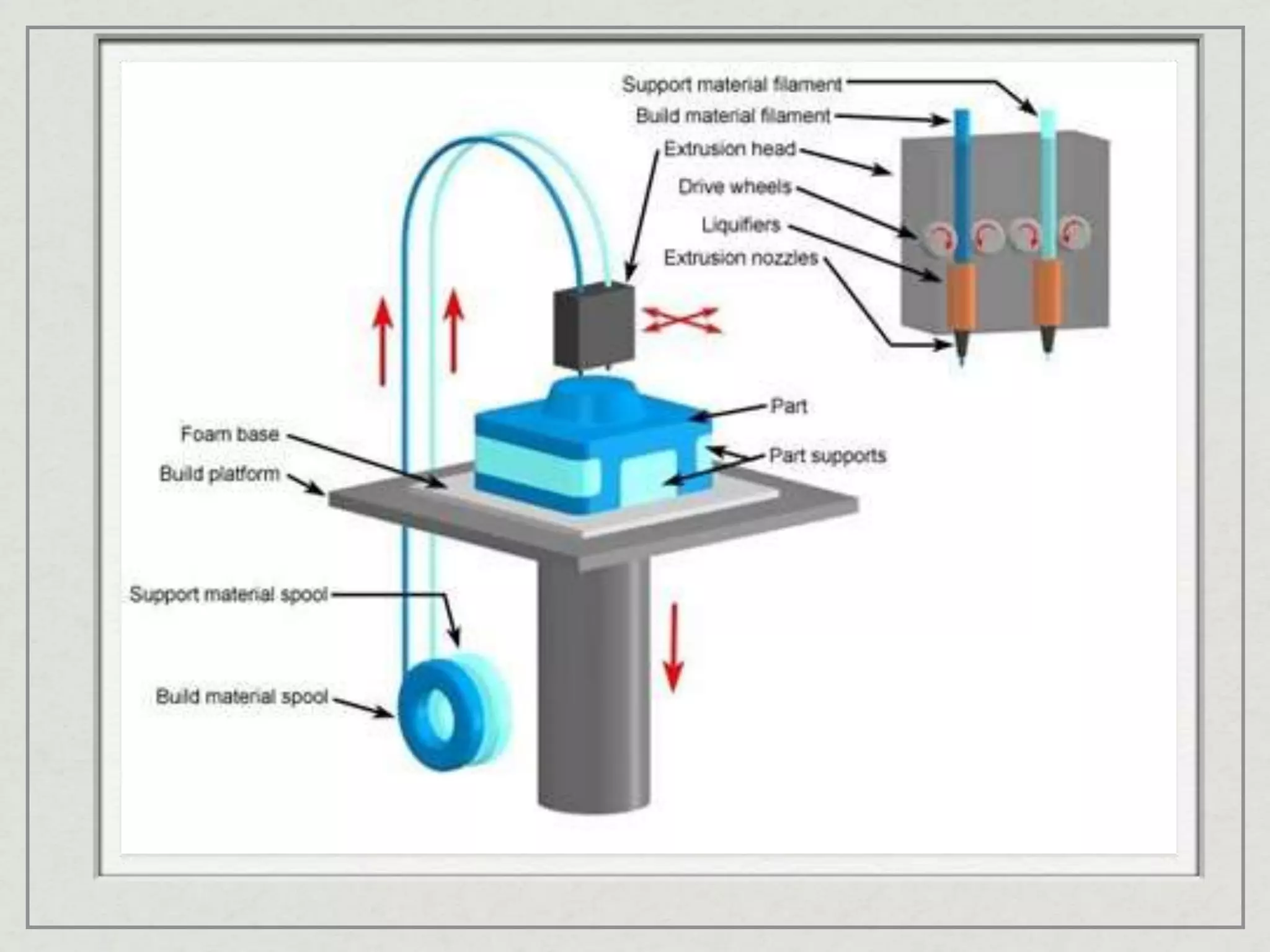

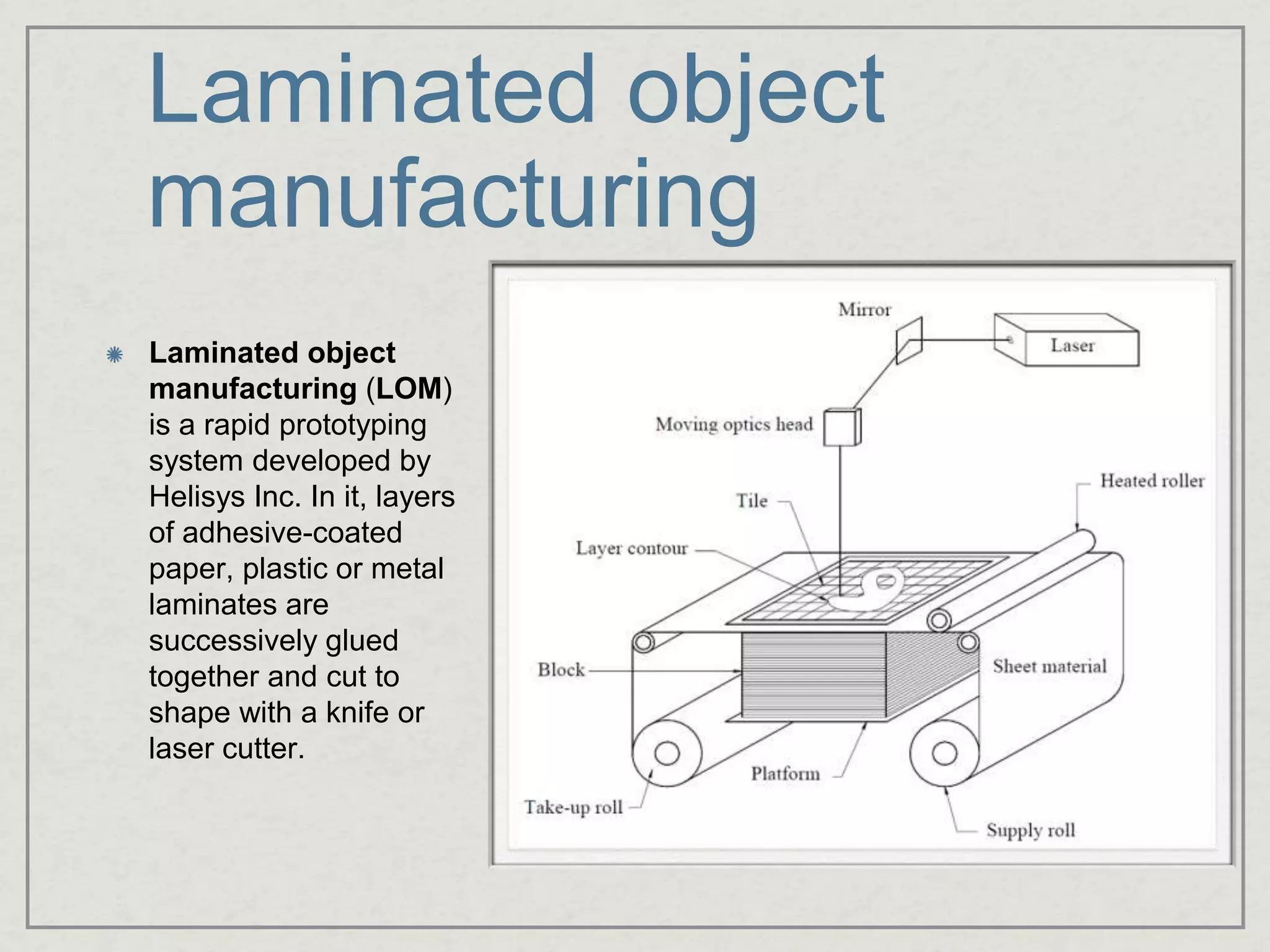

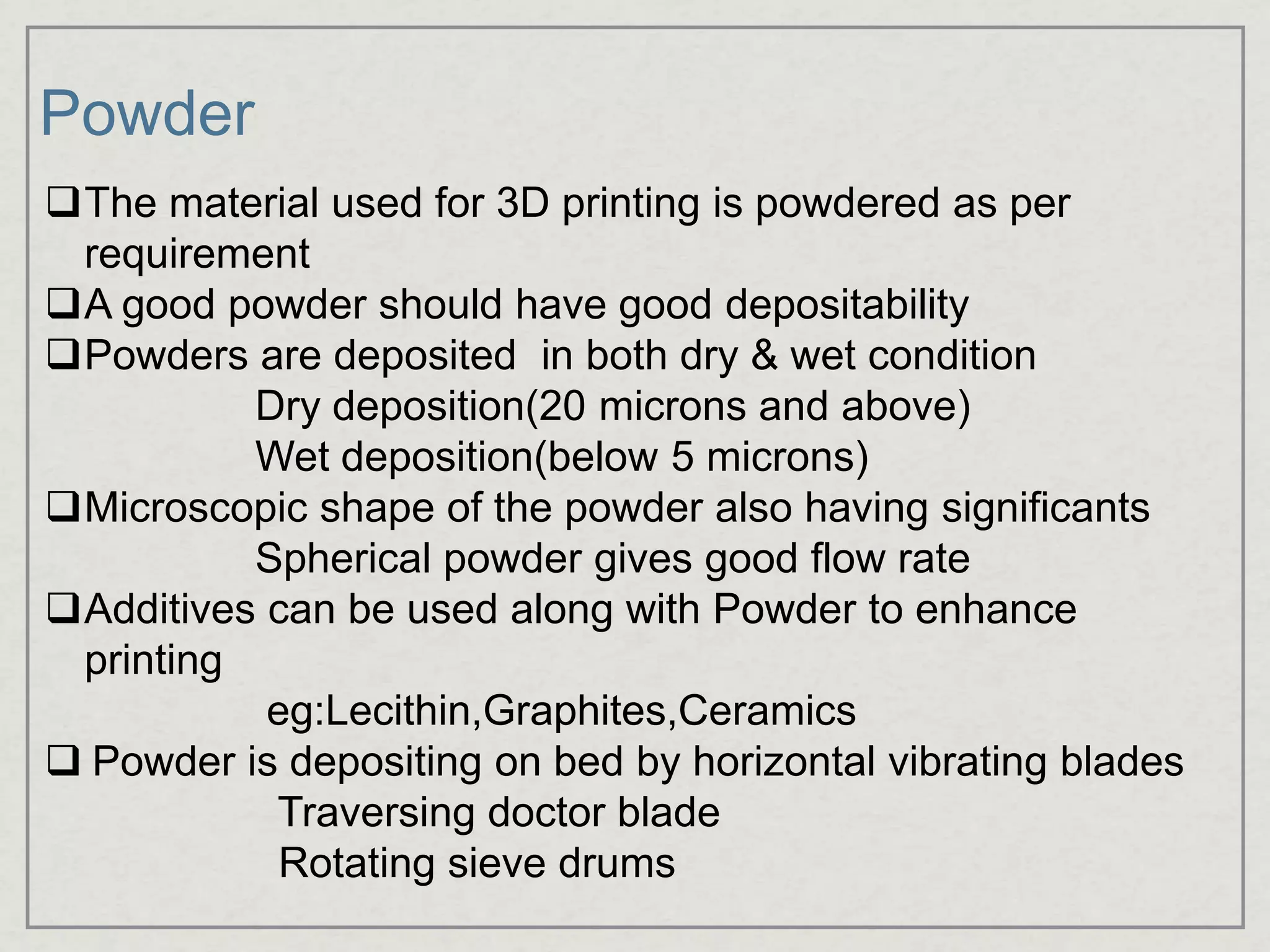

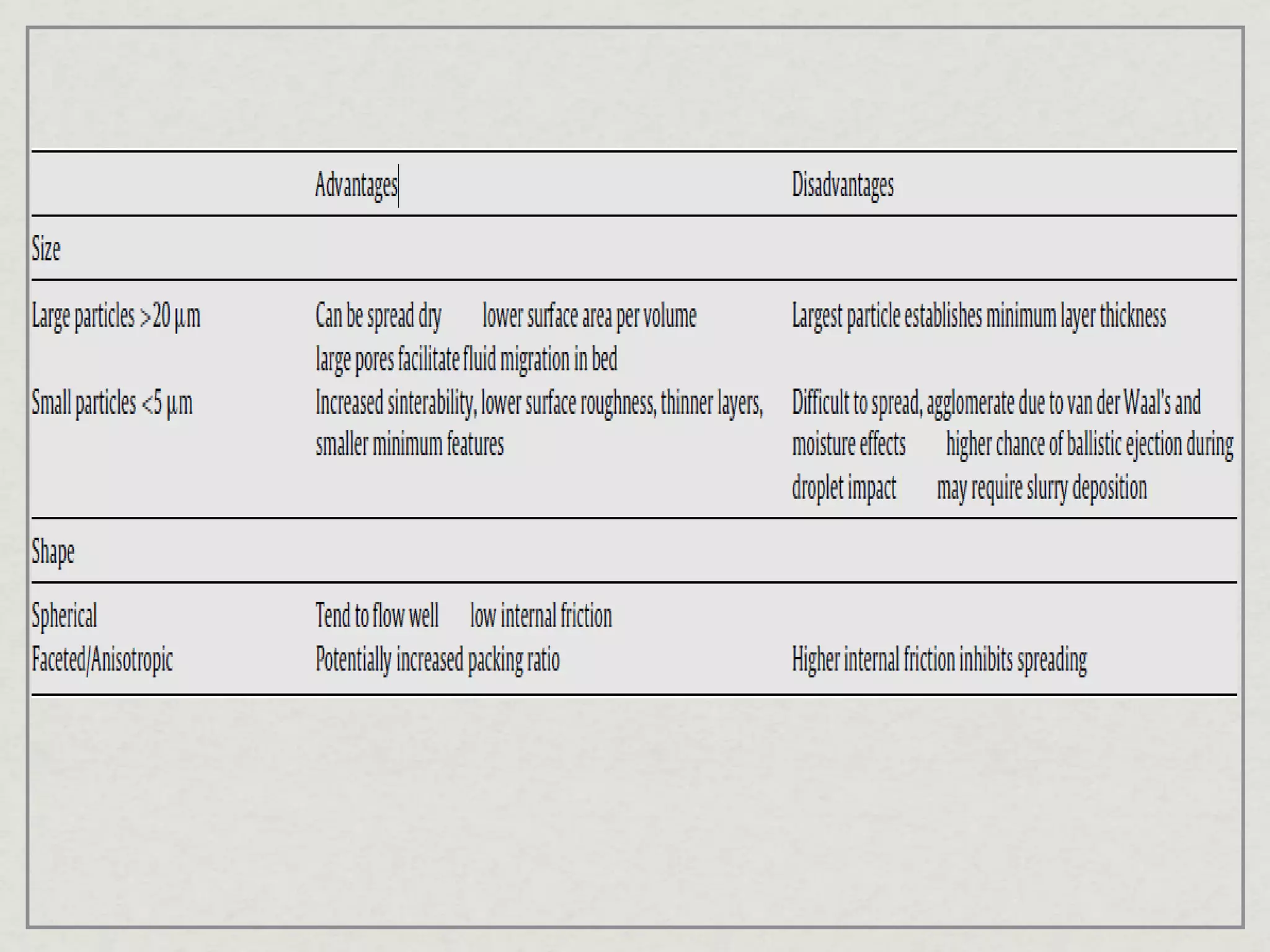

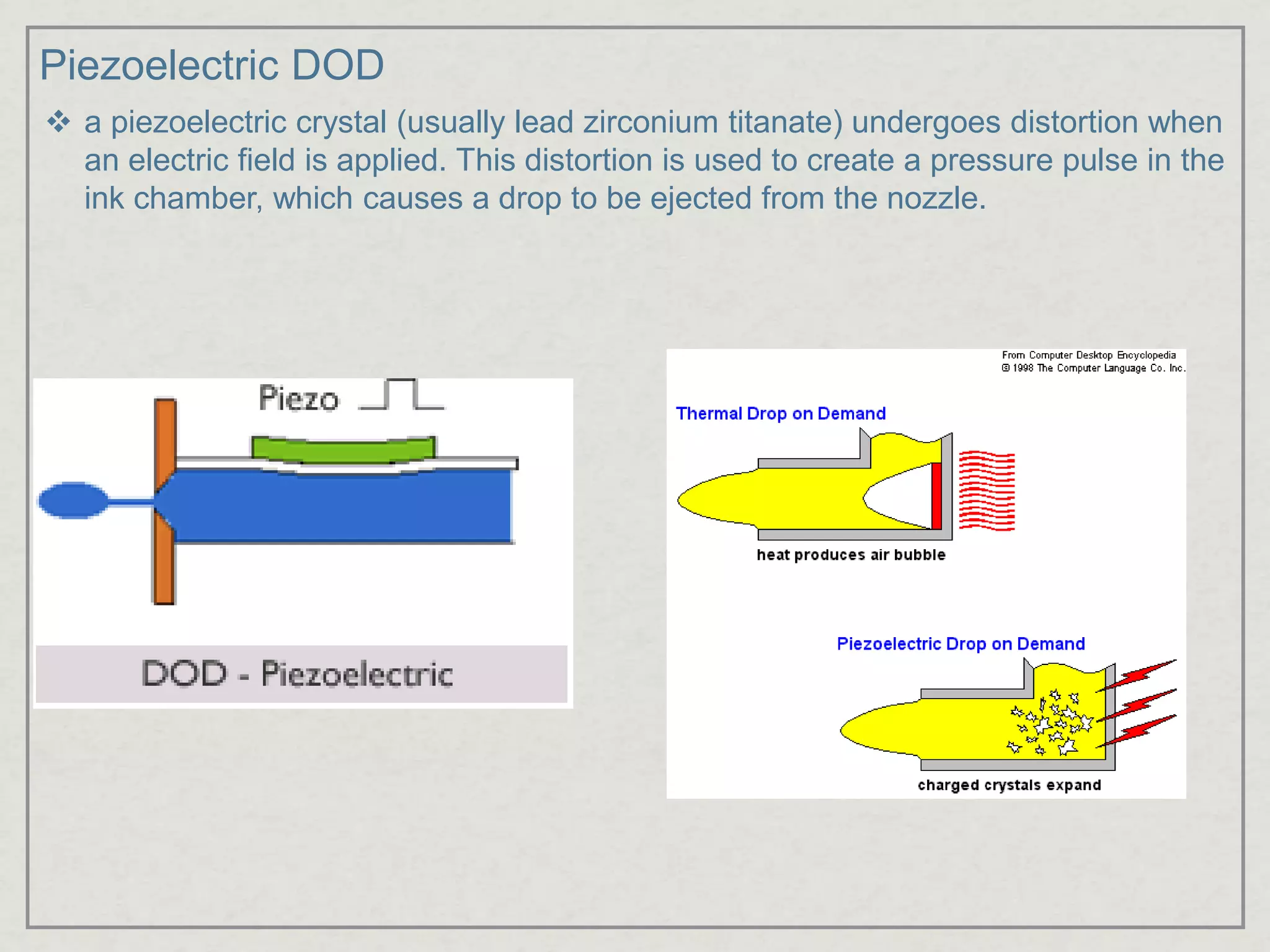

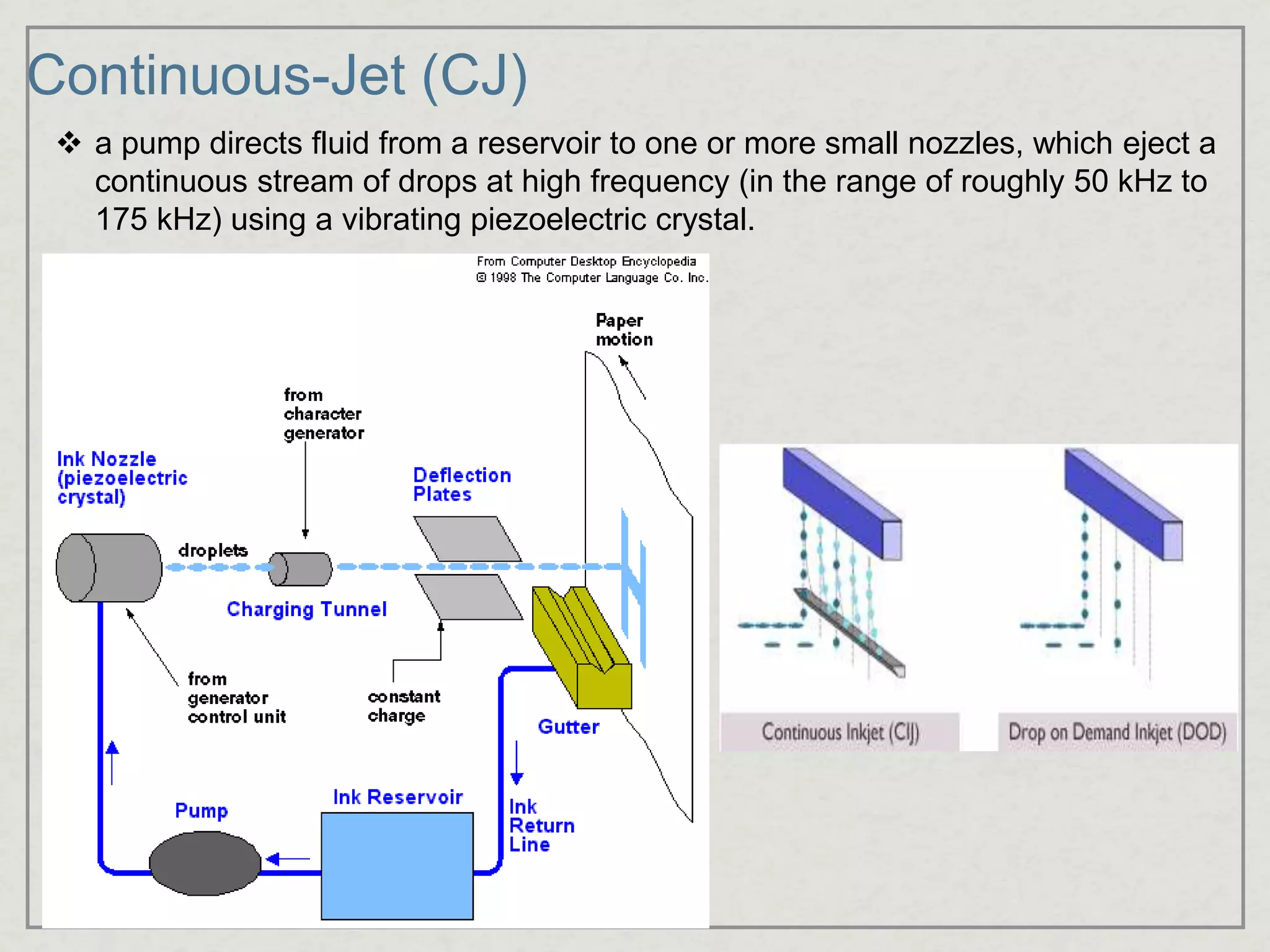

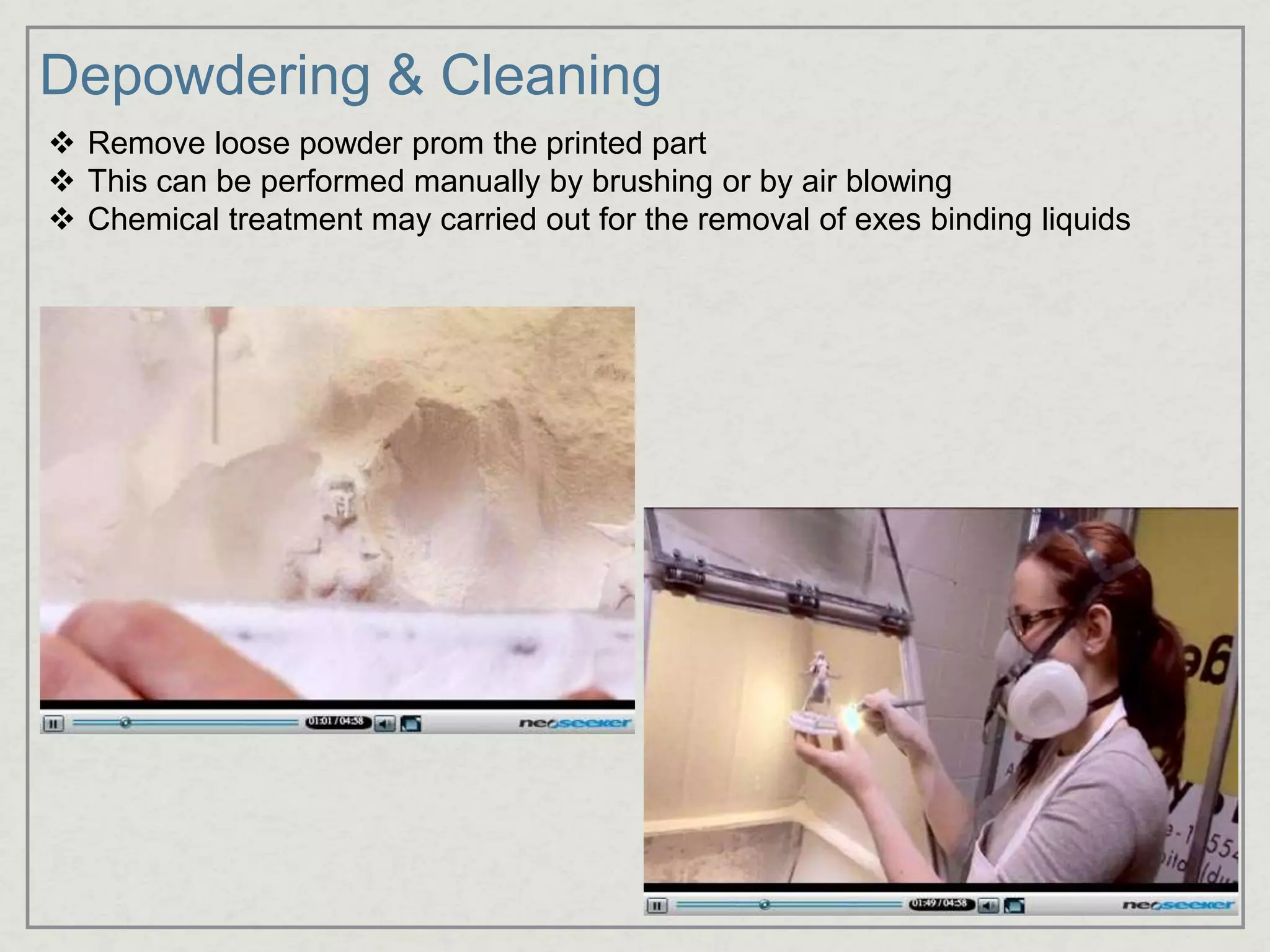

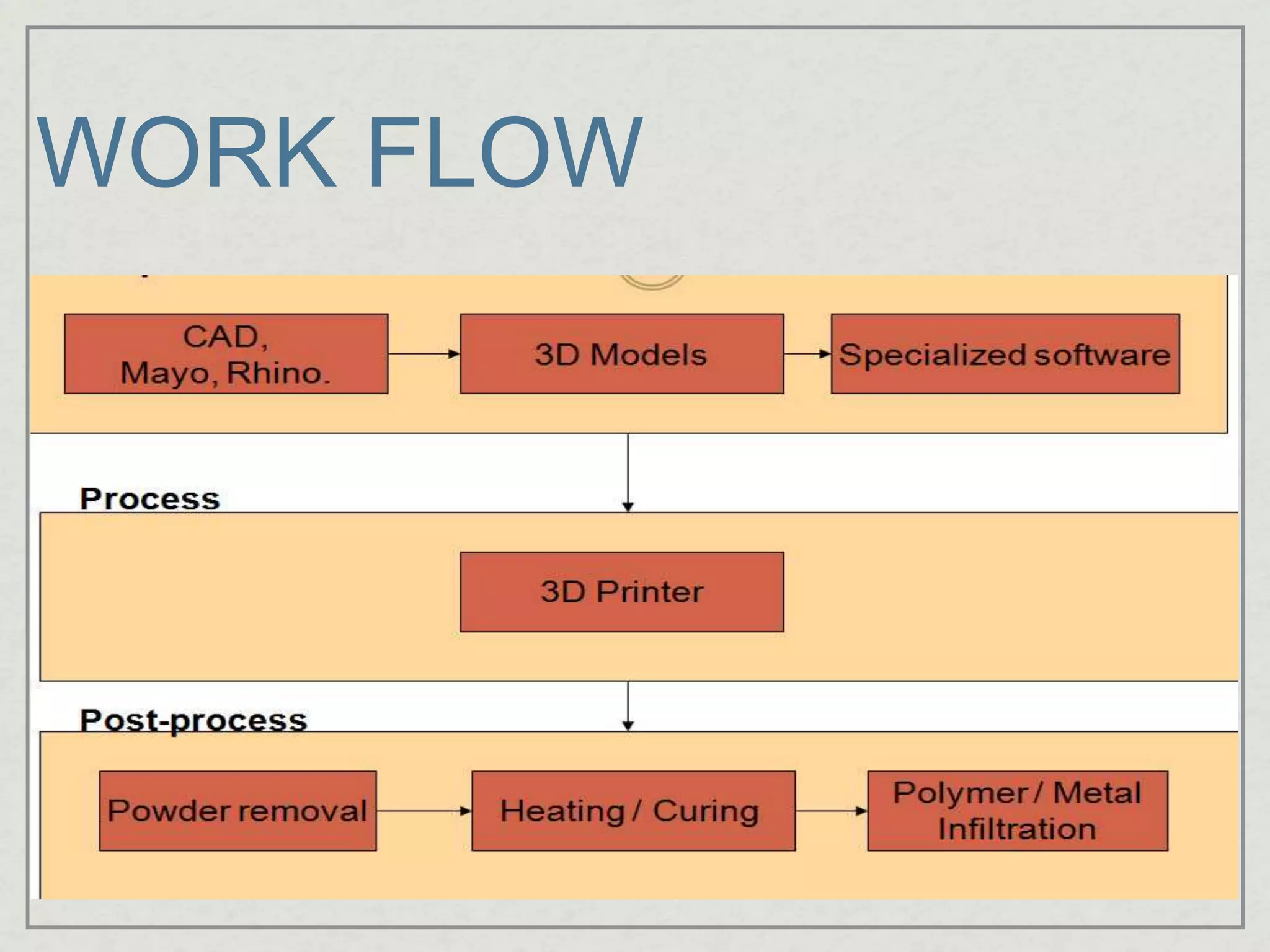

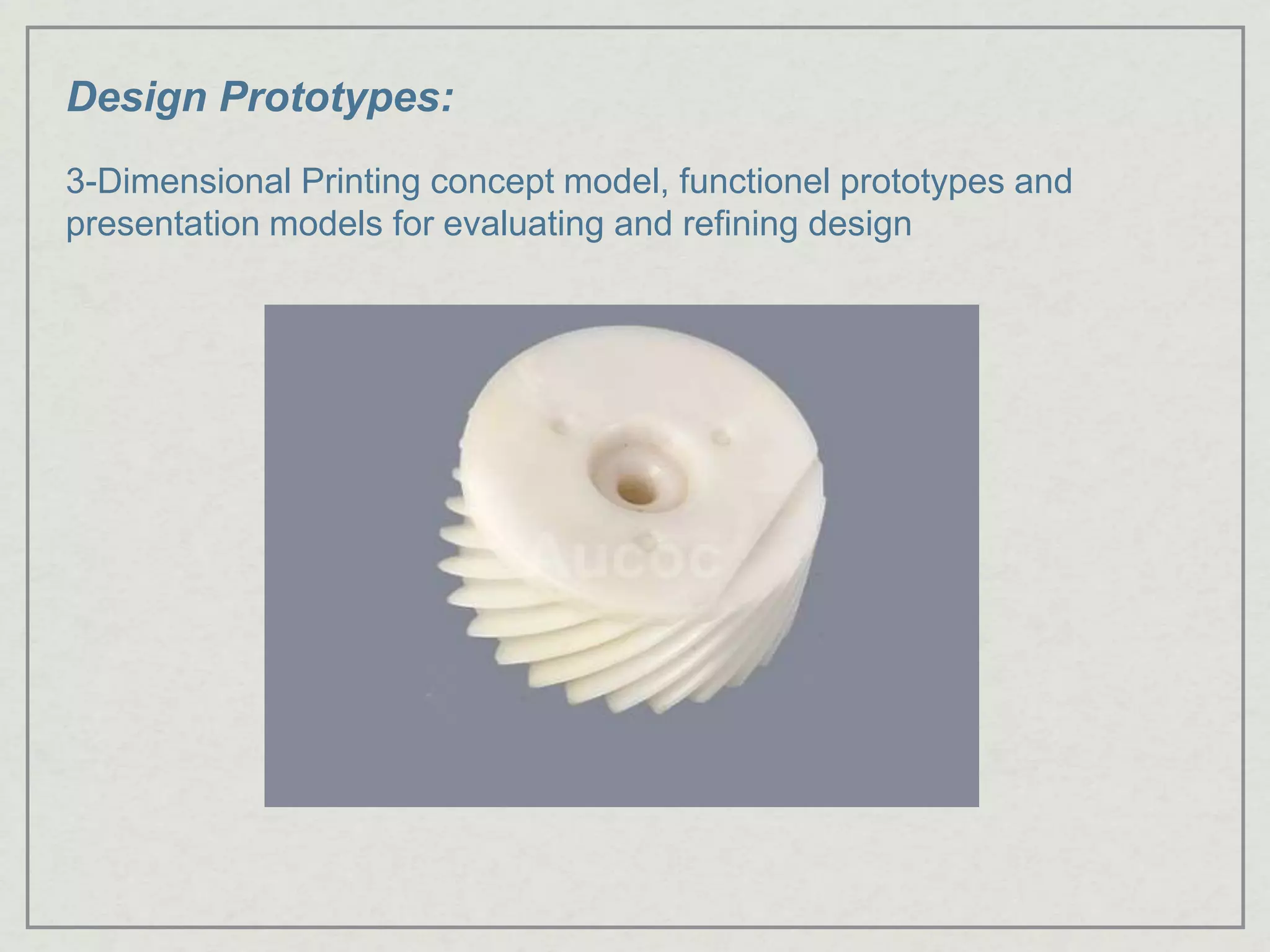

The document provides an overview of 3D printing technology, detailing its history, methods, materials, and applications. Key techniques discussed include stereolithography, selective laser sintering, and fused deposition modeling, alongside the process of printing and post-processing treatments. It highlights the benefits of 3D printing for innovation, cost reduction, and its potential to alter manufacturing dynamics across various industries.