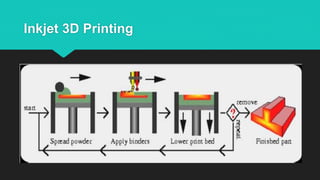

This document discusses 3D printing. It begins by defining 3D printing as using an additive process to print physical 3D objects from digital models by laying down successive layers of material. The document then covers various 3D printing technologies like stereolithography, selective laser sintering, and multi-jet modeling which use different materials and layering methods. Applications of 3D printing discussed include design prototyping and healthcare. The document concludes that 3D printing allows for fast communication of design ideas by creating physical 3D models and prototypes directly from digital files.