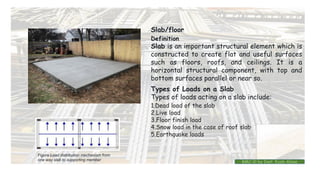

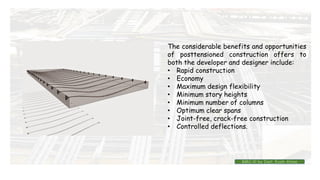

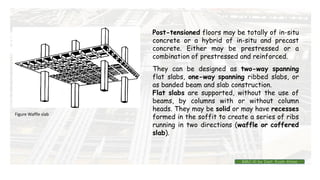

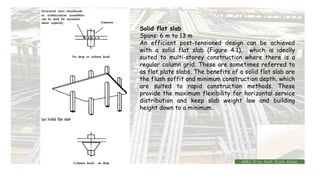

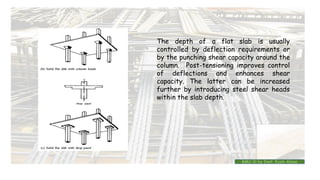

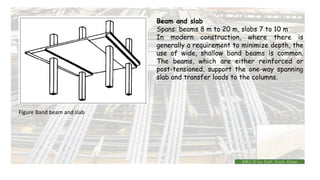

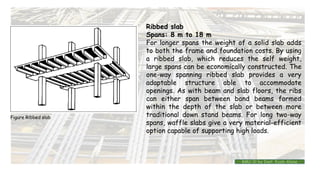

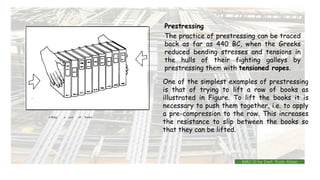

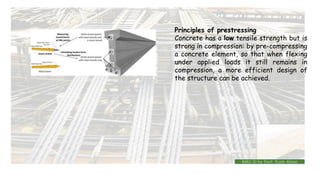

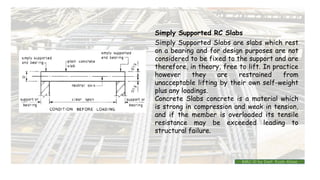

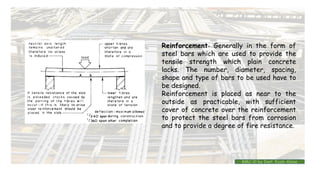

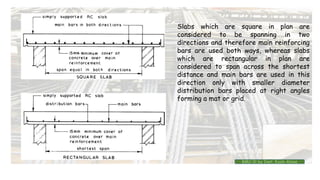

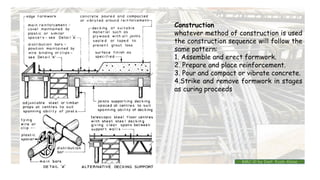

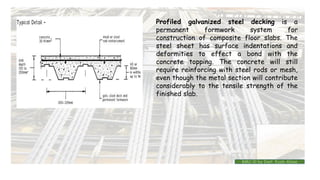

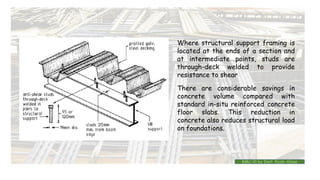

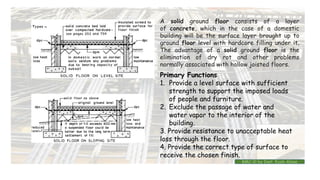

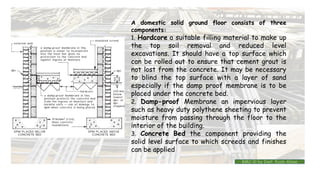

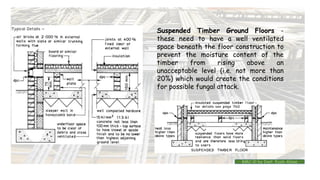

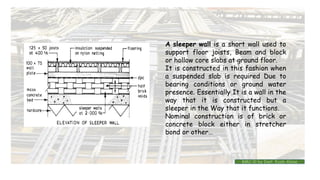

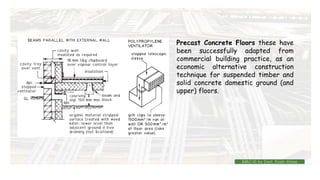

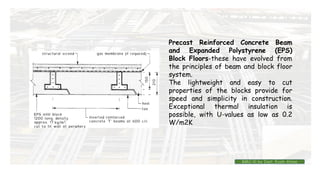

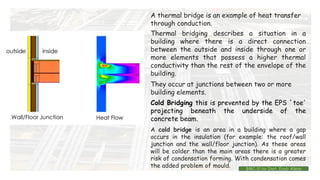

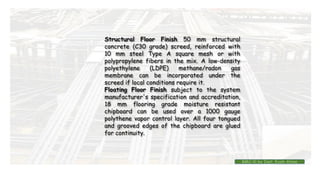

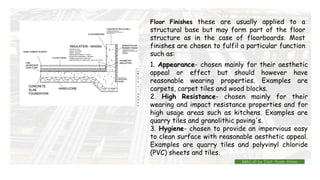

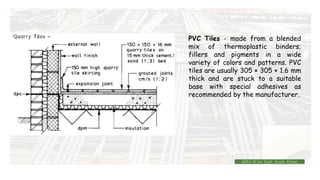

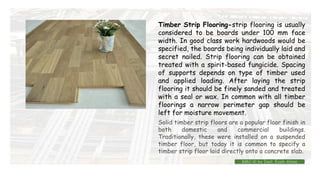

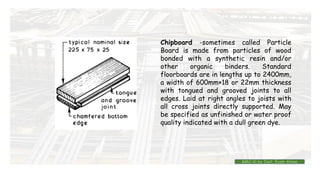

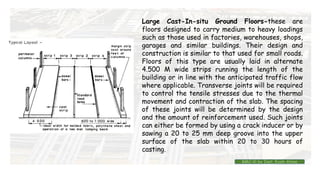

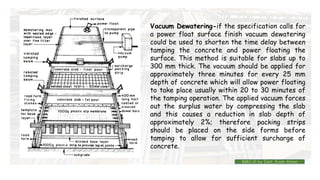

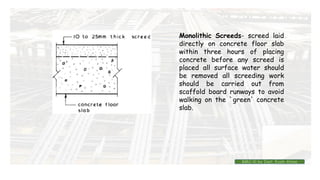

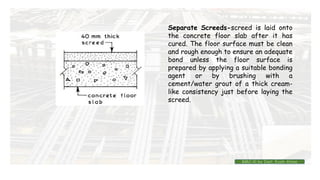

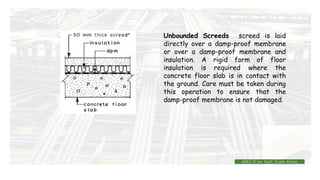

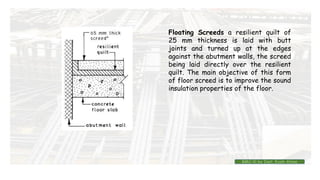

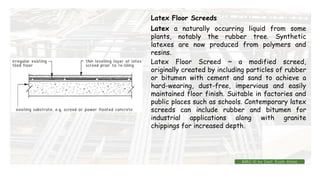

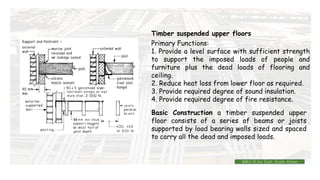

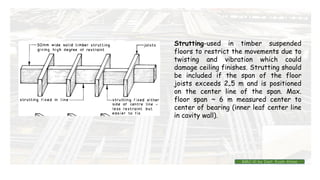

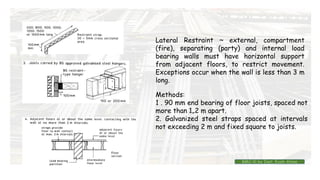

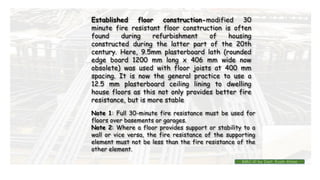

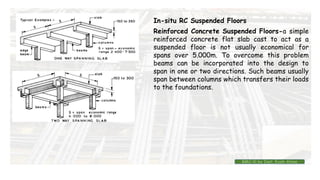

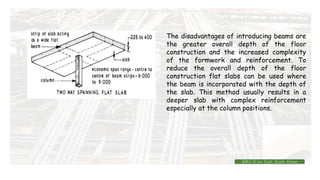

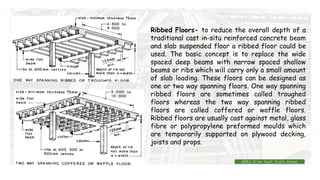

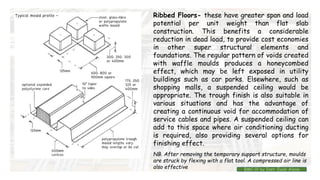

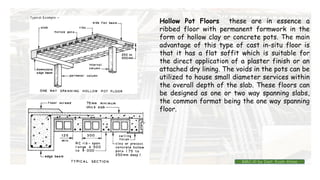

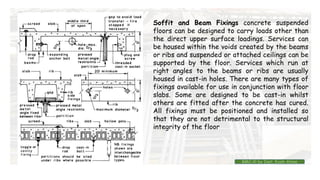

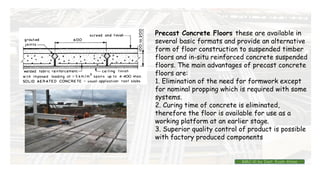

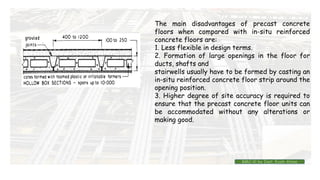

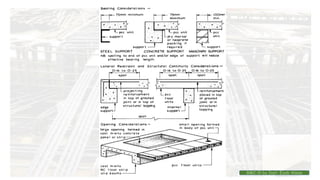

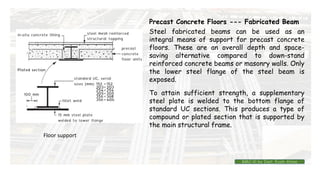

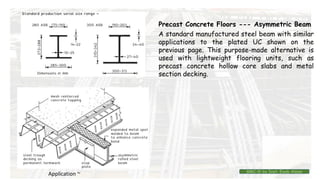

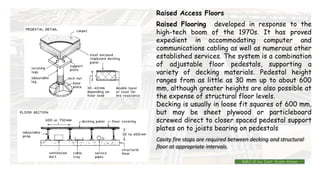

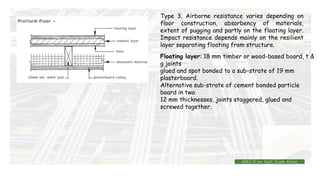

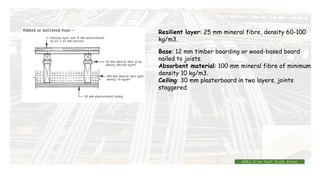

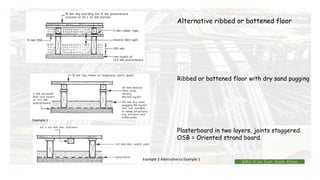

The document discusses various types of concrete slabs and their structural applications in building construction, detailing their definitions, classifications, and load considerations. It focuses on the characteristics of reinforced and post-tensioned slabs, along with different design options tailored for specific building needs and loading scenarios. The text also emphasizes construction methods and materials, highlighting the importance of proper reinforcement and finishing techniques for achieving functional, aesthetic, and durable floor systems.