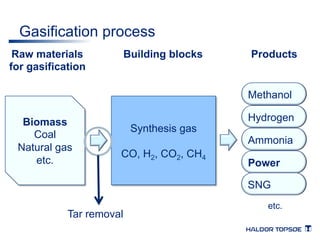

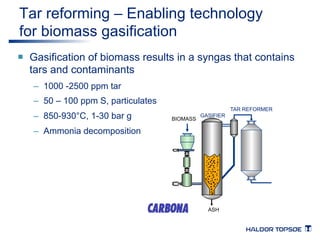

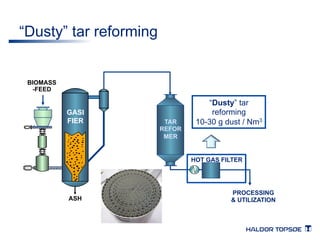

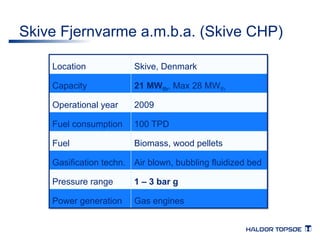

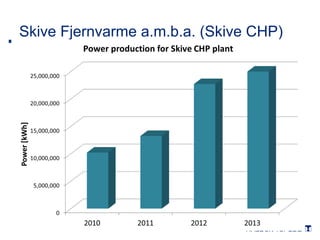

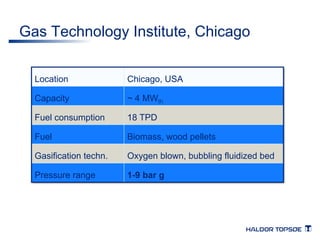

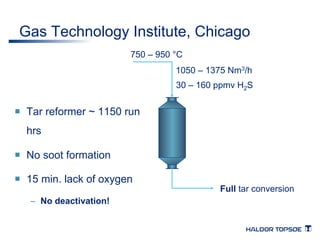

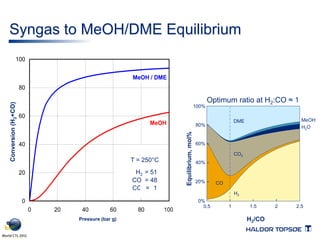

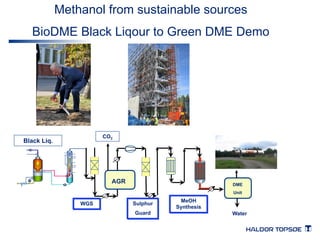

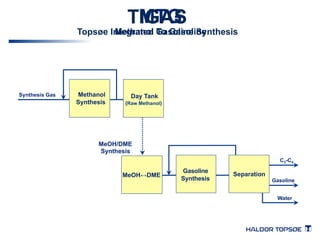

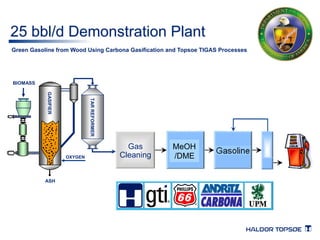

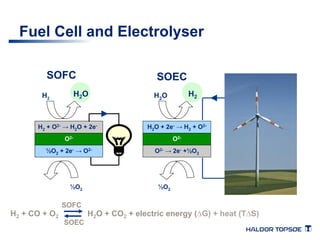

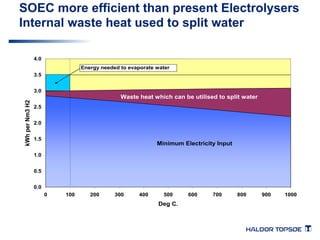

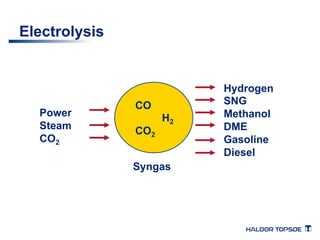

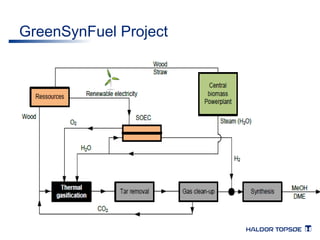

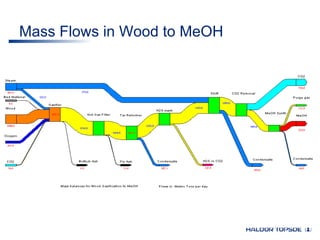

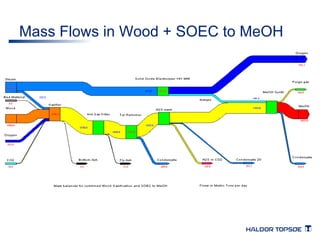

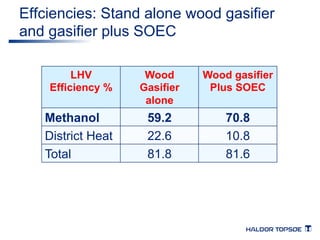

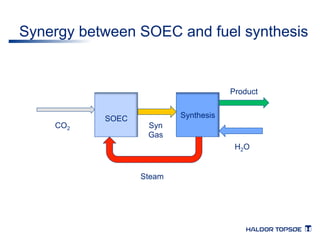

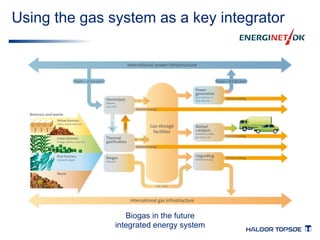

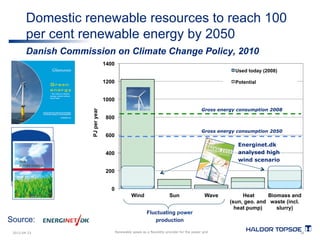

The document discusses advancements in catalytic process technology for producing alternative fuels from renewable sources, particularly focusing on syngas generated from gasification of biomass. It highlights the successful implementation of tar reforming processes and demonstrates the conversion of black liquor to DME at a commercial scale, as well as the integration of solid oxide electrolysis cells (SOEC) with biomass gasification to enhance efficiency. The findings suggest that these technologies can significantly contribute to renewable energy goals and improve fuel synthesis efficiency.