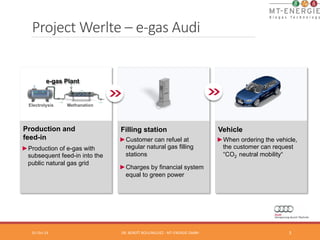

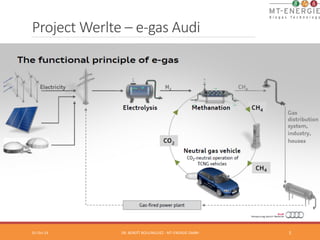

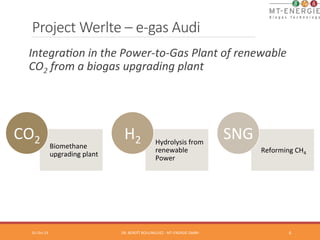

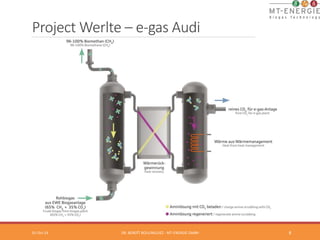

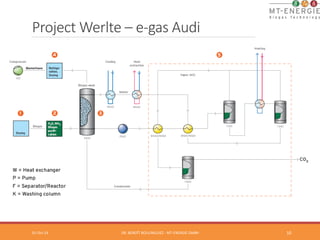

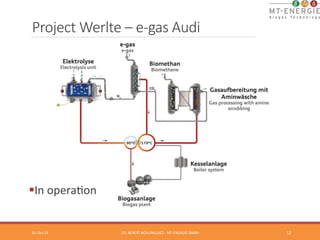

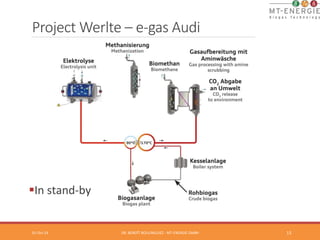

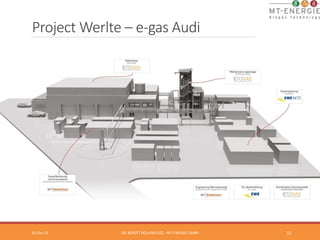

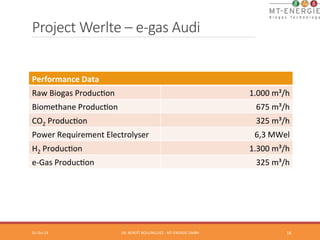

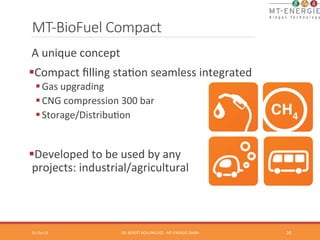

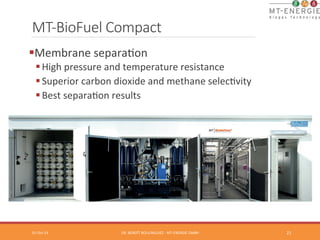

The document describes the e-gas project in Werlte, Germany, which is the first industrial-scale power-to-gas plant. The plant uses excess electricity from renewable sources to produce synthetic natural gas (SNG) through the process of electrolysis and methanation. The SNG and biomethane produced will be injected into the natural gas grid to provide fuel for approximately 1,500 Audi A3 g-tron vehicles per year and contribute to CO2-neutral mobility. Additionally, the plant integrates CO2 from a nearby biogas upgrading facility to further optimize the energy and sustainability of the overall system.