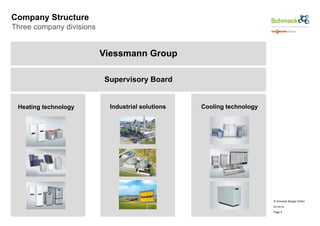

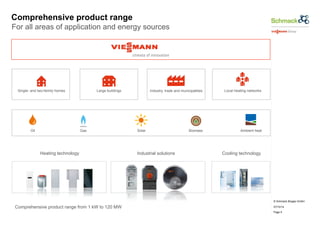

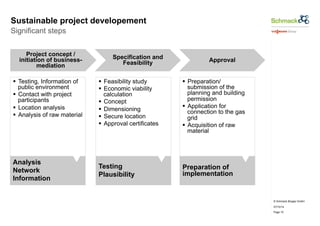

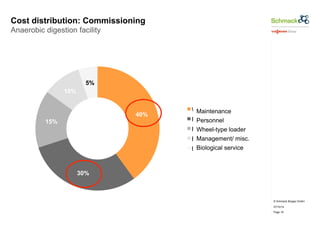

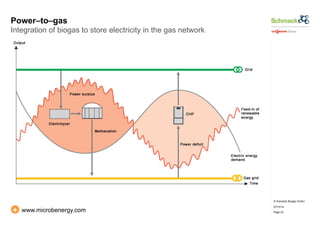

The document discusses Schmack Biogas, a member of the Viessmann Group. It summarizes Schmack's expertise in biogas project development and operation, including their experience with wet and dry anaerobic digestion technologies. The document also outlines Schmack's comprehensive services for technical support, biological support, and monitoring and optimization of biogas plants. Future challenges mentioned include efficient plant operation, knowledge transfer, and combining biogas and power-to-gas technologies.