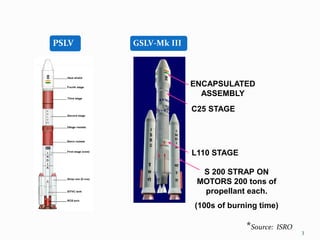

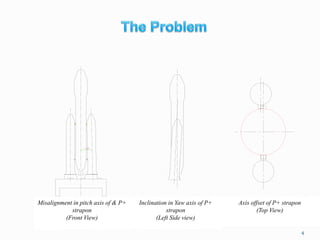

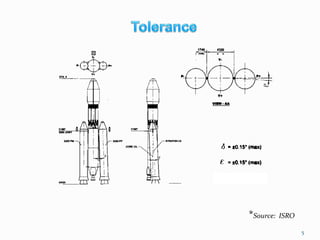

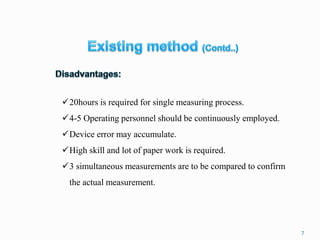

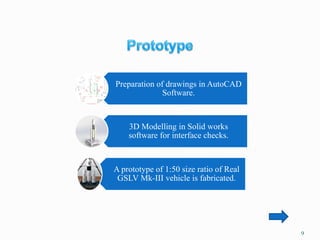

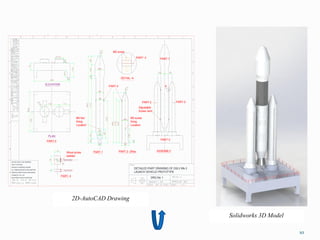

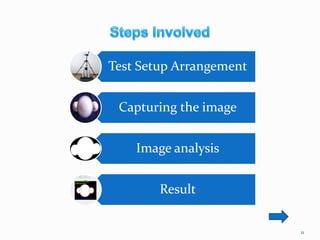

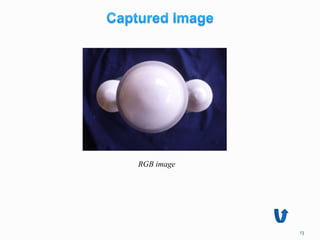

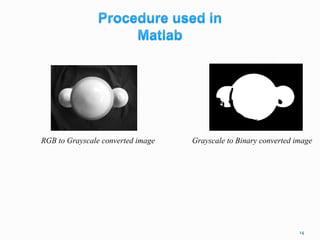

The document discusses a project aimed at utilizing machine vision techniques to detect alignment errors in space launch vehicles, specifically ISRO's GSLV Mk-III. It outlines the advantages of this method over traditional inspection approaches, including speed, accuracy, and the ability to monitor vehicle alignment continuously during operations. The project includes the creation of a prototype for testing and the use of CAD software for design and modeling.