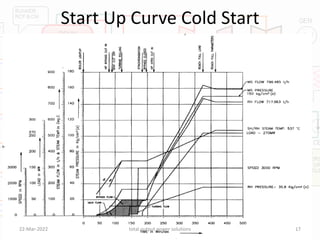

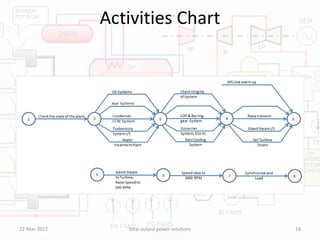

The document outlines the operational procedures for starting and managing a coal-based thermal power plant, emphasizing efficiency in bringing the unit online and minimizing startup costs. Key activities include checks for auxiliary systems, boiler and turbine readiness, synchronization with the grid, and gradual load increases following strict operational protocols. It details specific system checks required before and during startup to ensure smooth and efficient plant operations.