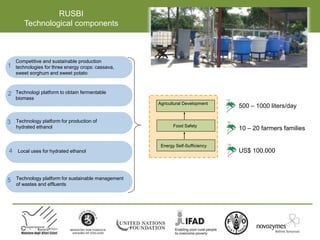

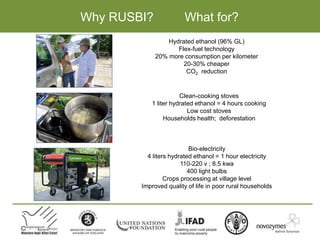

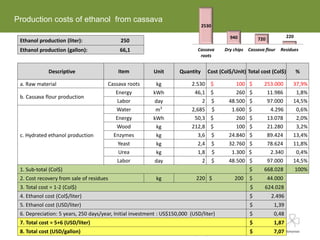

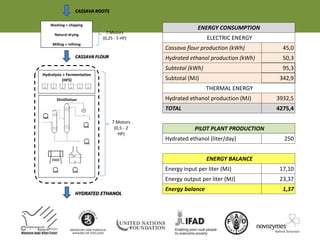

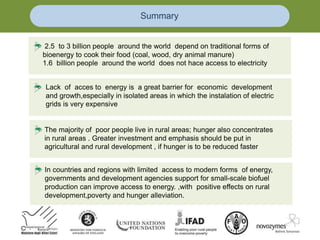

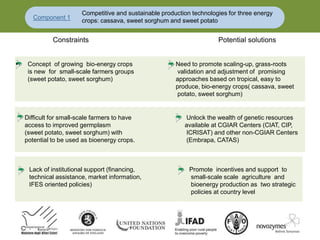

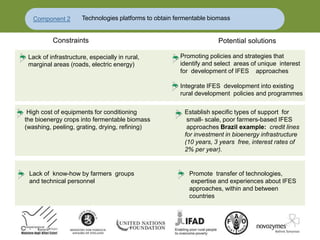

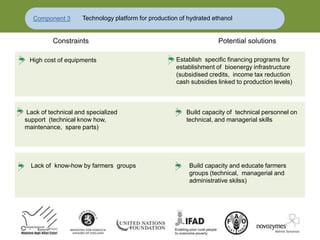

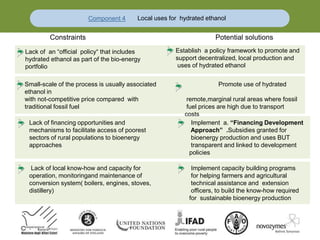

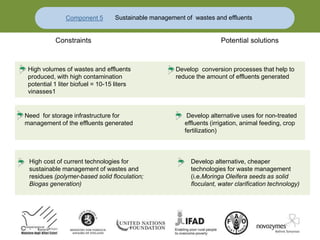

Rural communities in developing countries often lack access to reliable and affordable energy sources. Small-scale bioenergy projects using crops like cassava, sweet sorghum, and sweet potato have potential to improve energy access and promote rural development. The RUSBI project tests technology platforms for sustainable production of bioenergy at the village level in Colombia. The project focuses on developing competitive crop production, obtaining fermentable biomass, producing hydrated ethanol, local applications of ethanol, and managing wastes. While some technologies worked well, challenges remain around farmer access to improved varieties, processing costs, and waste management. Addressing these challenges could help scale up small-scale, community-based bioenergy models.