This document provides an overview of a coal handling plant (CHP). It discusses what a CHP is, its main components and processes. The key points covered include:

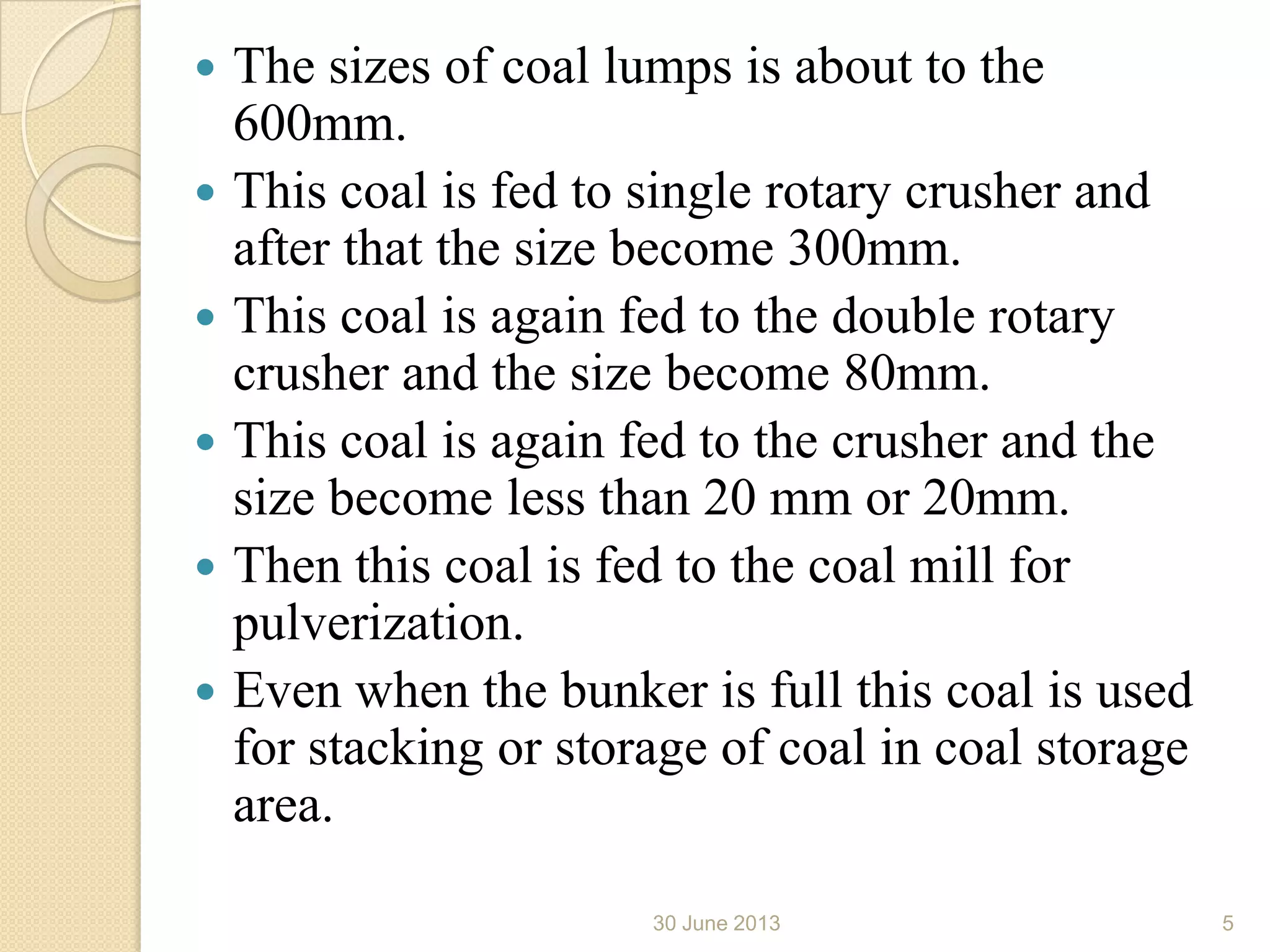

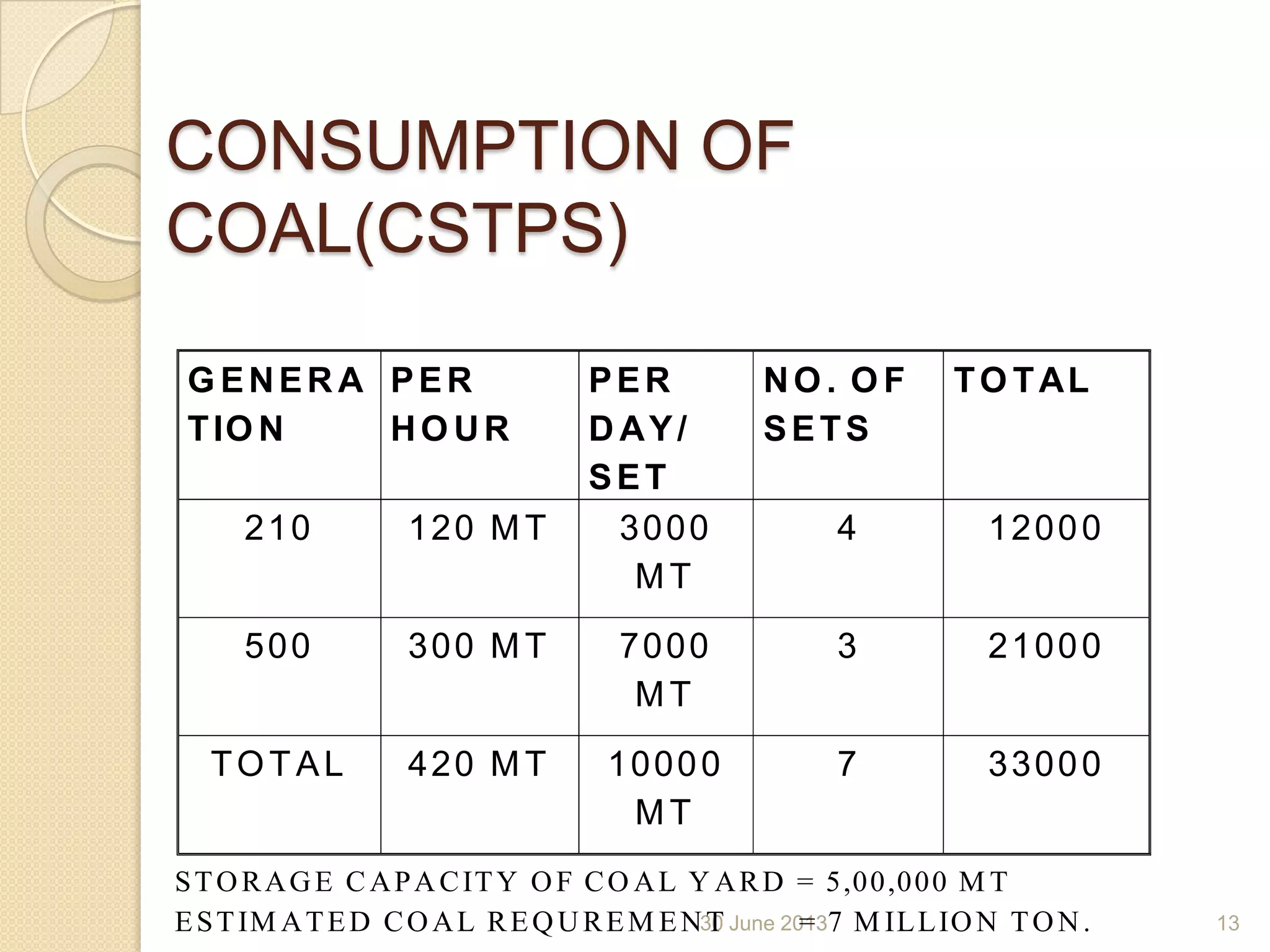

- A CHP receives, processes, stores and feeds coal to boiler bunkers. Its main goal is to supply processed coal to coal mills.

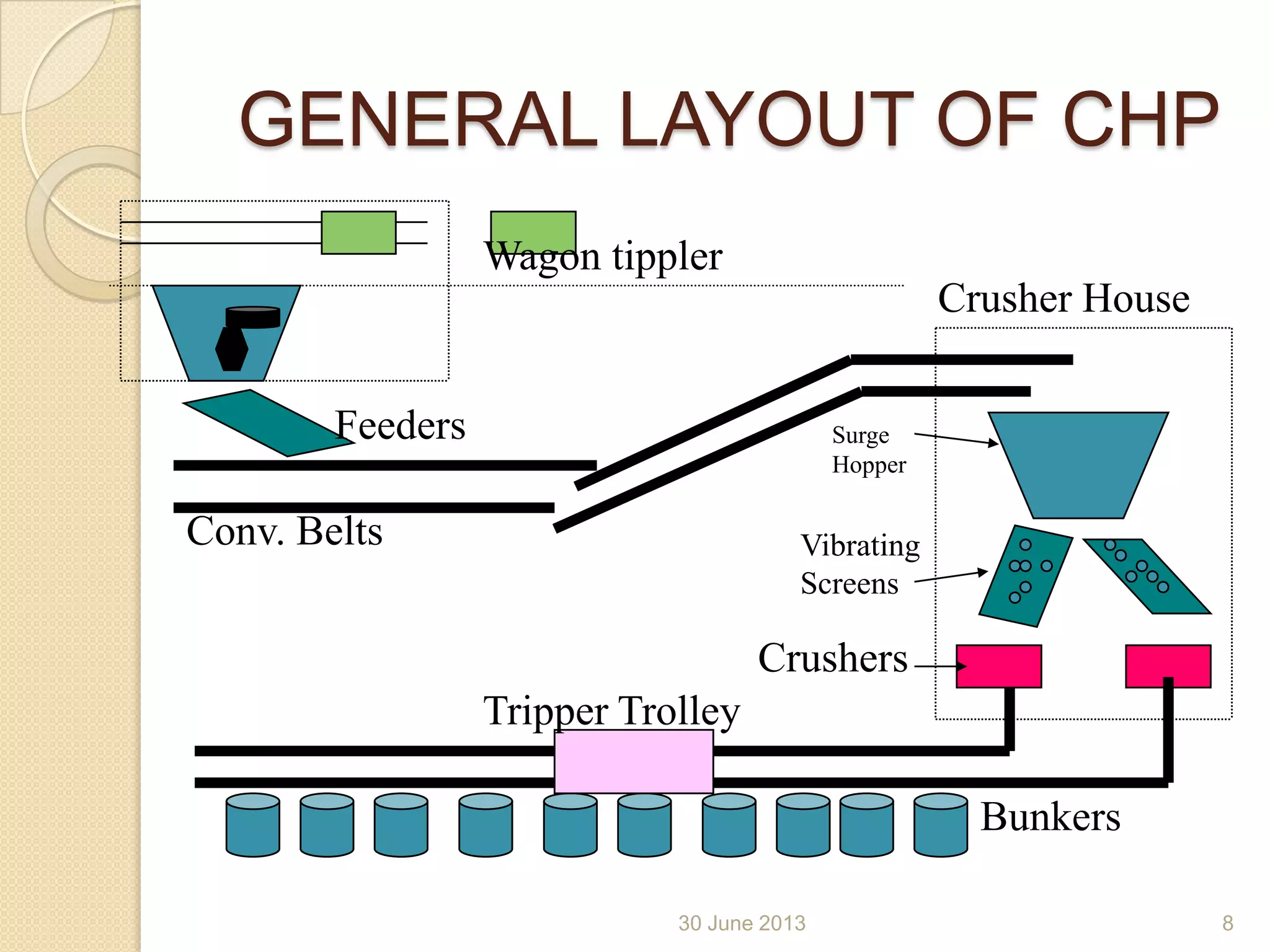

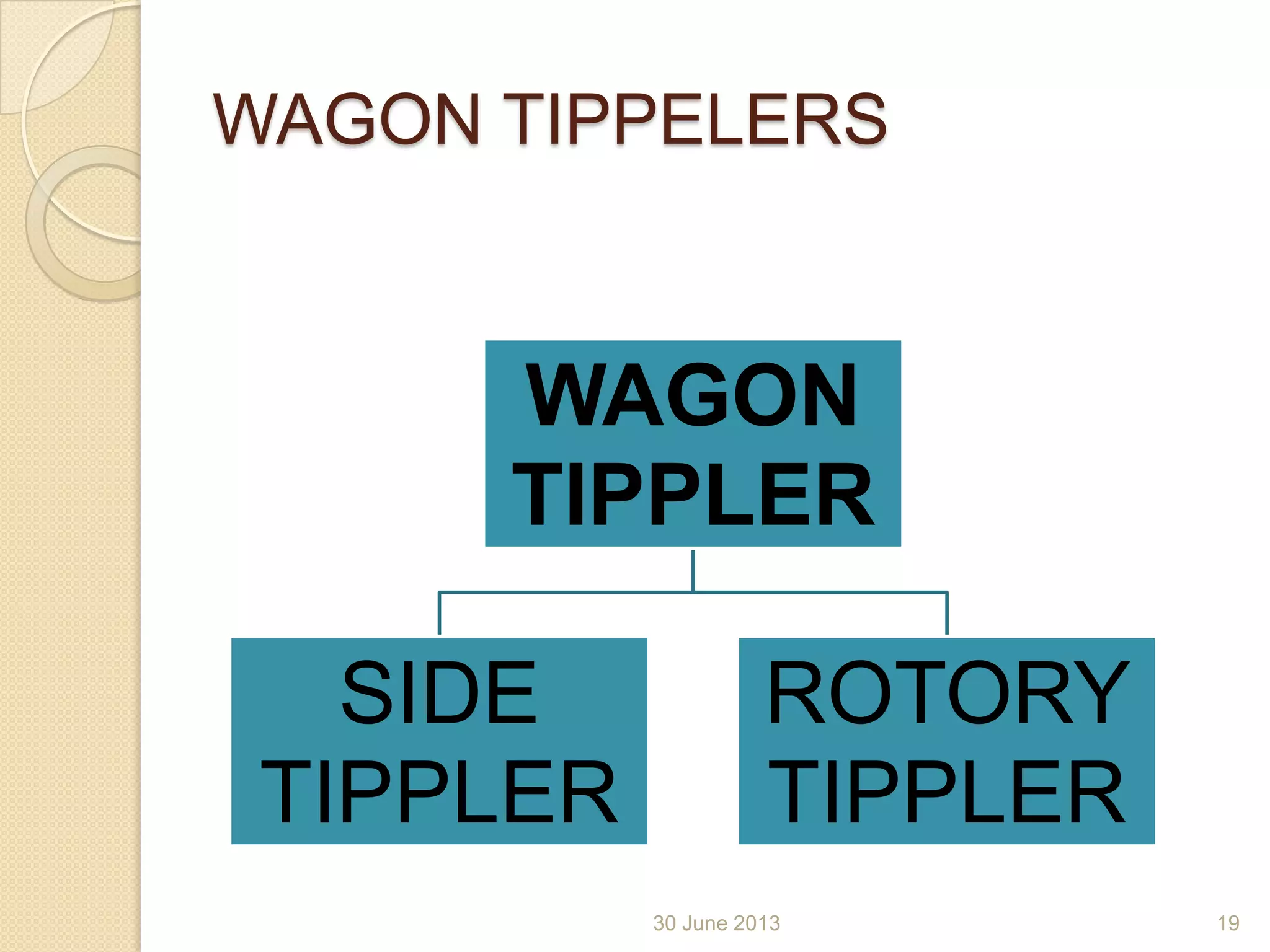

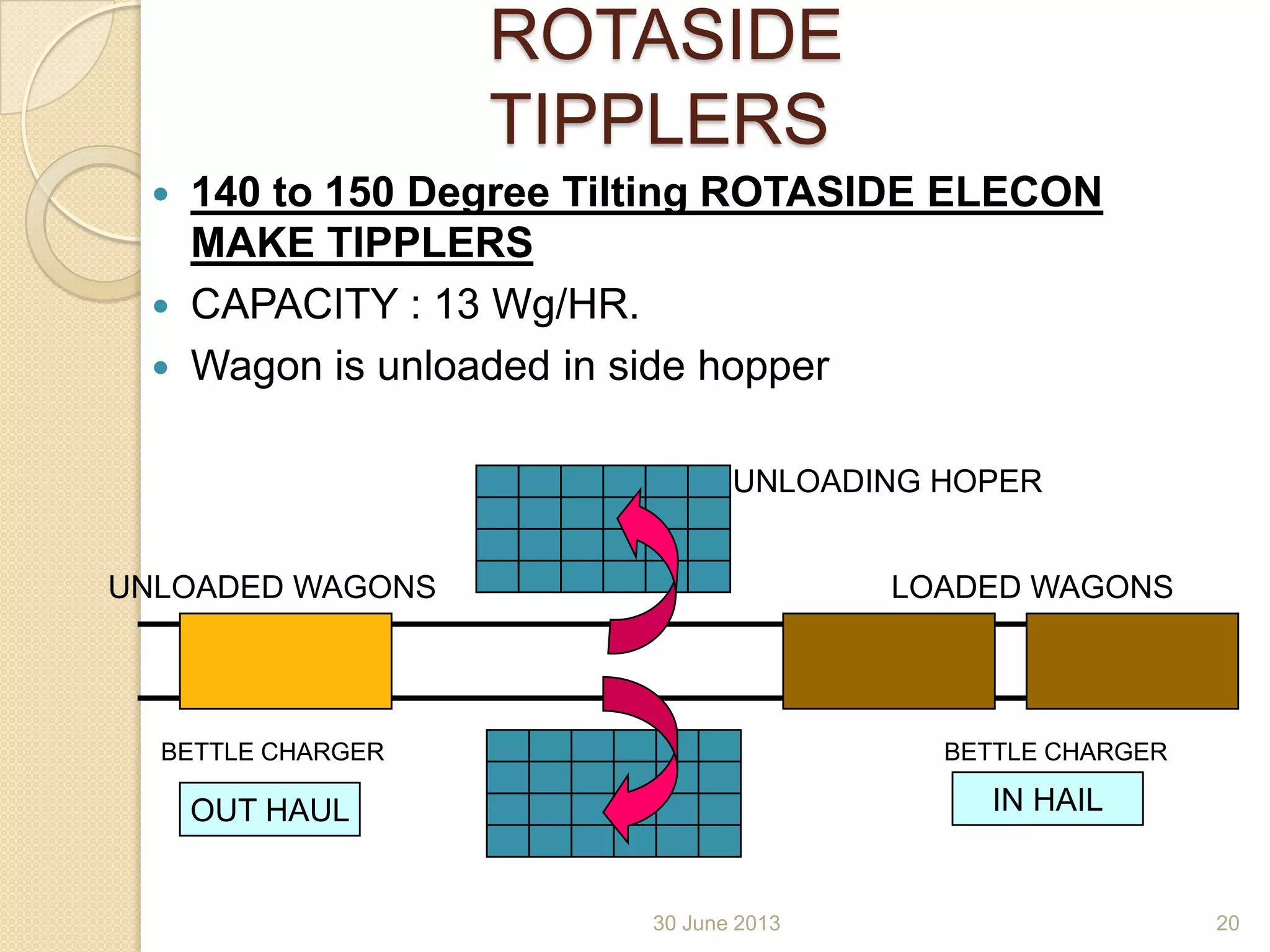

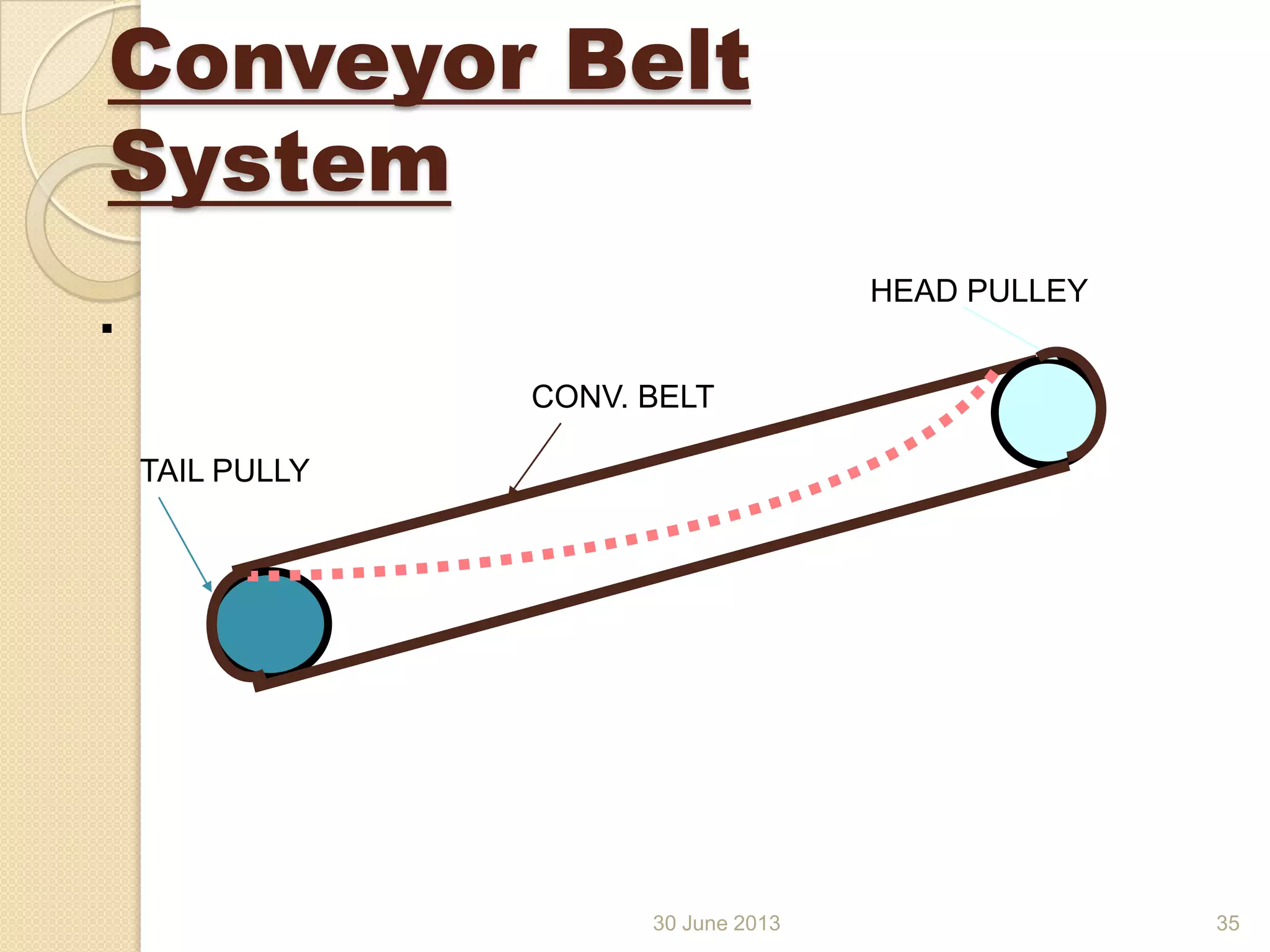

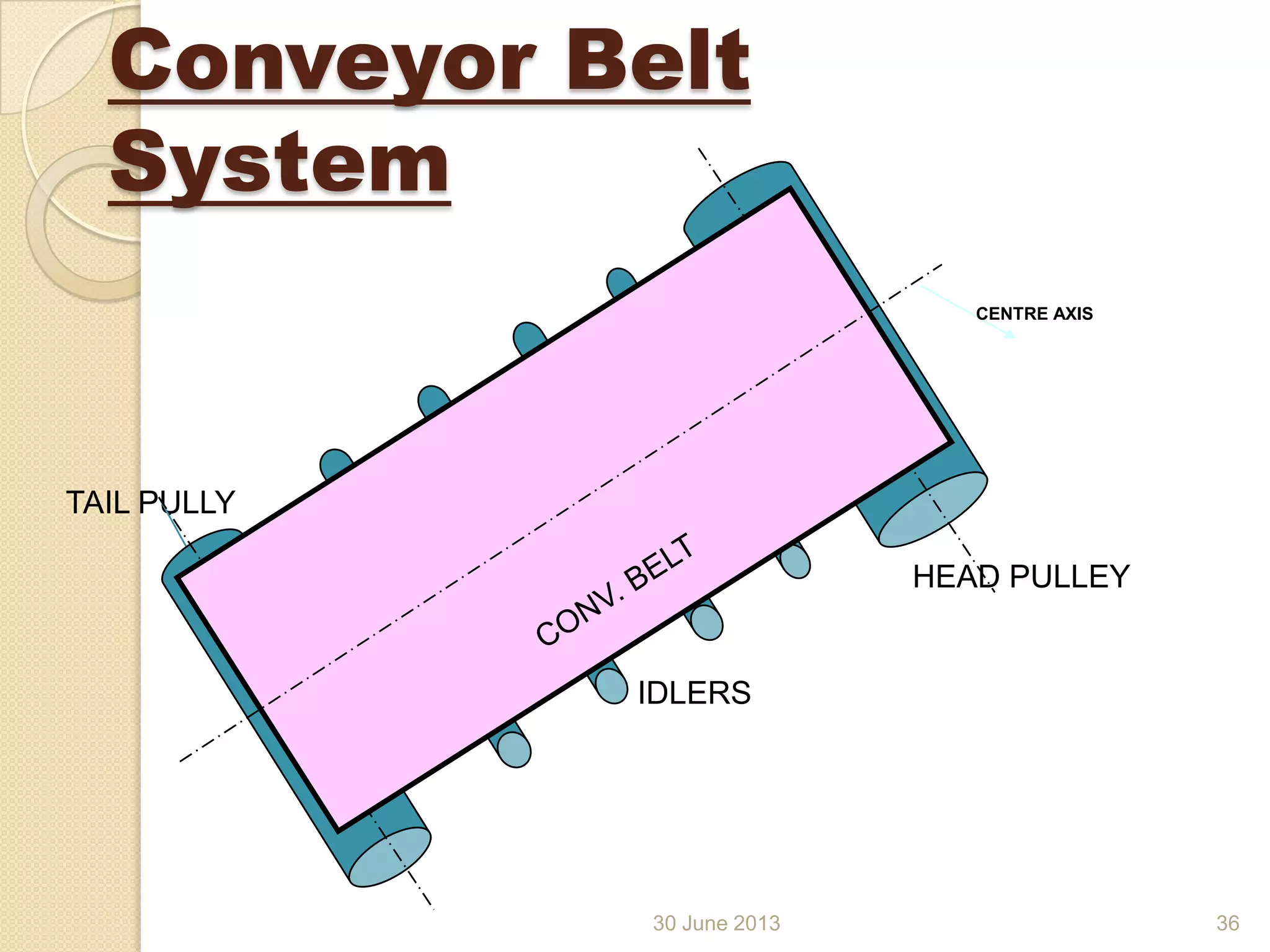

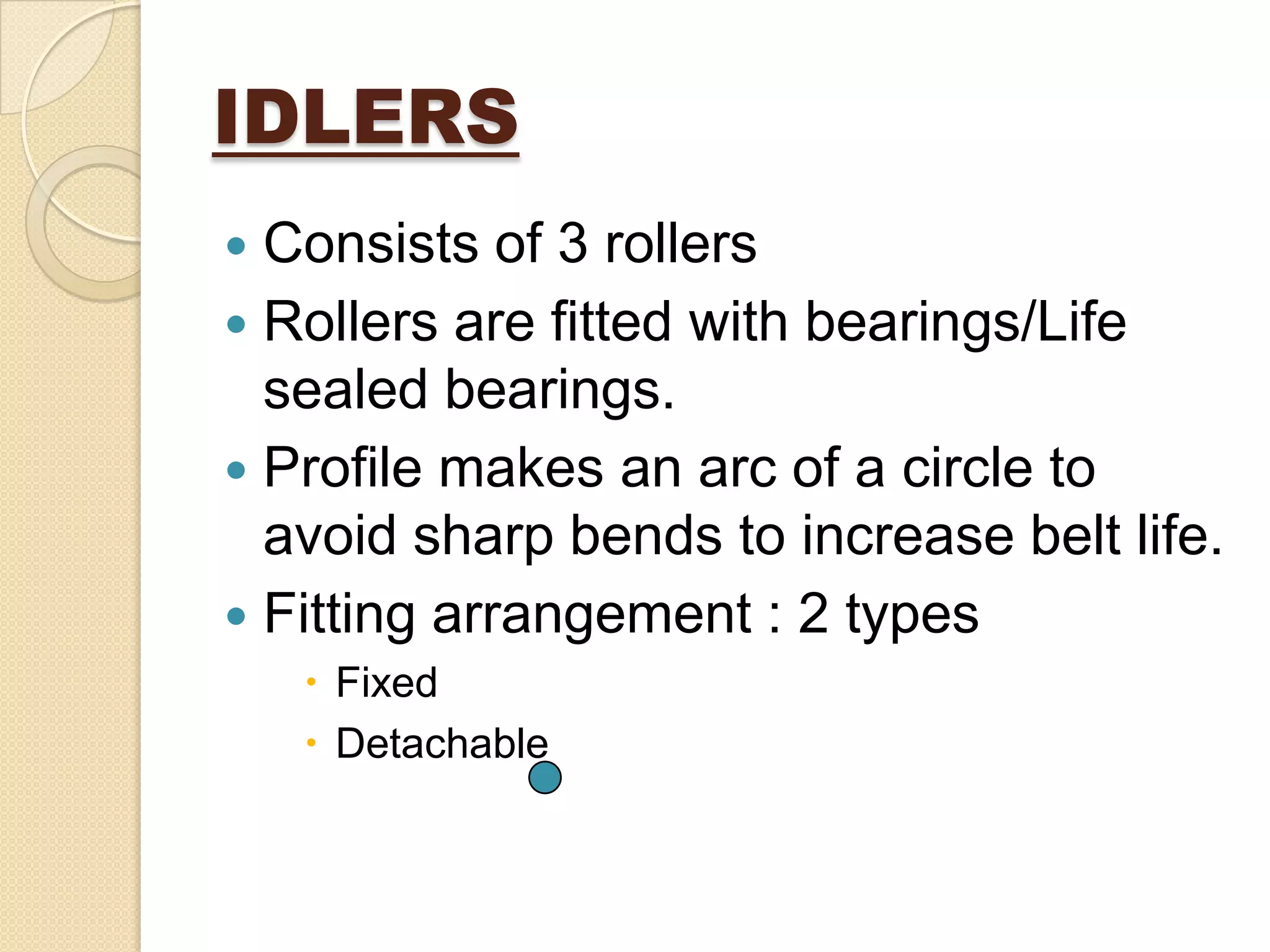

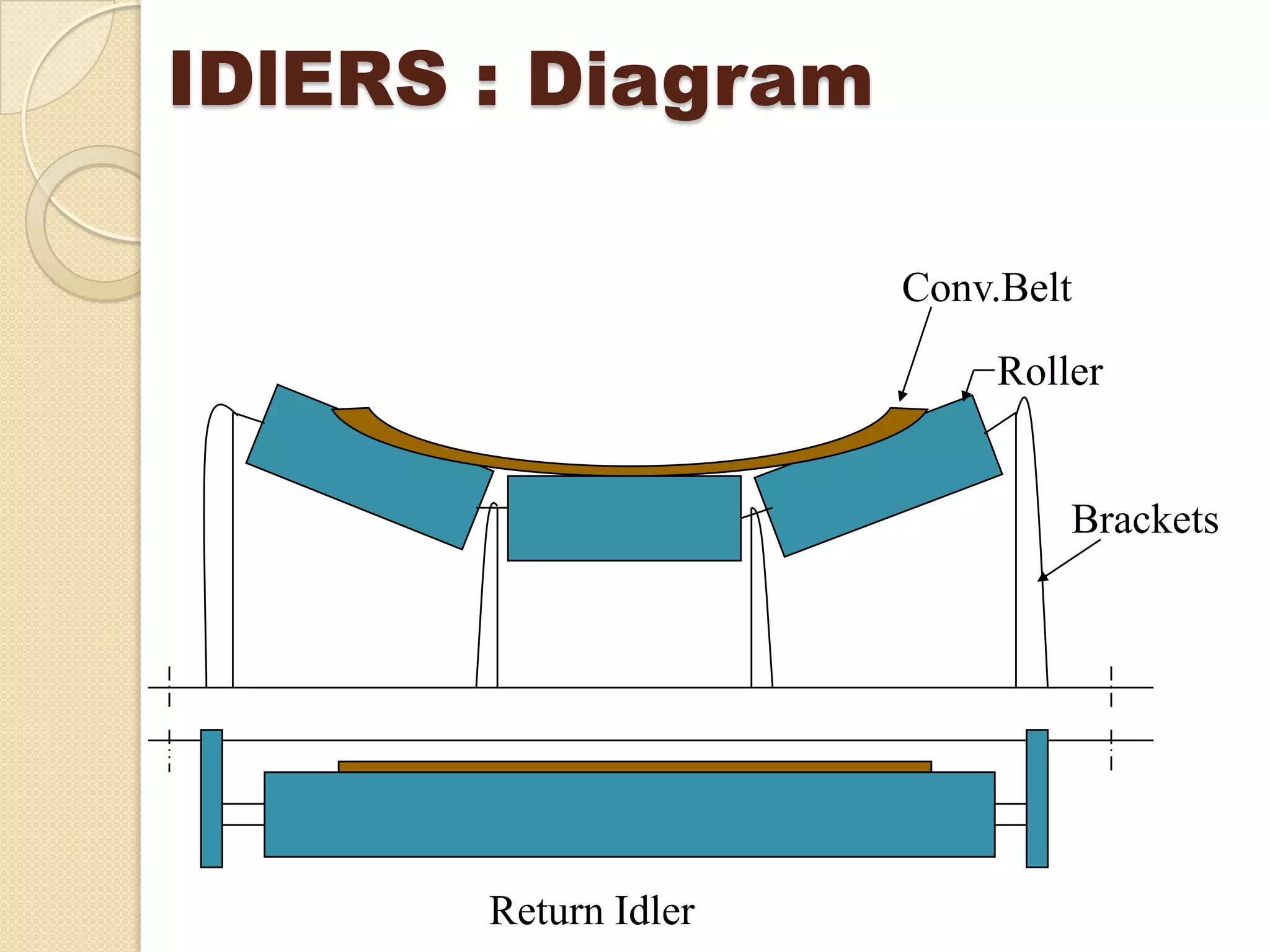

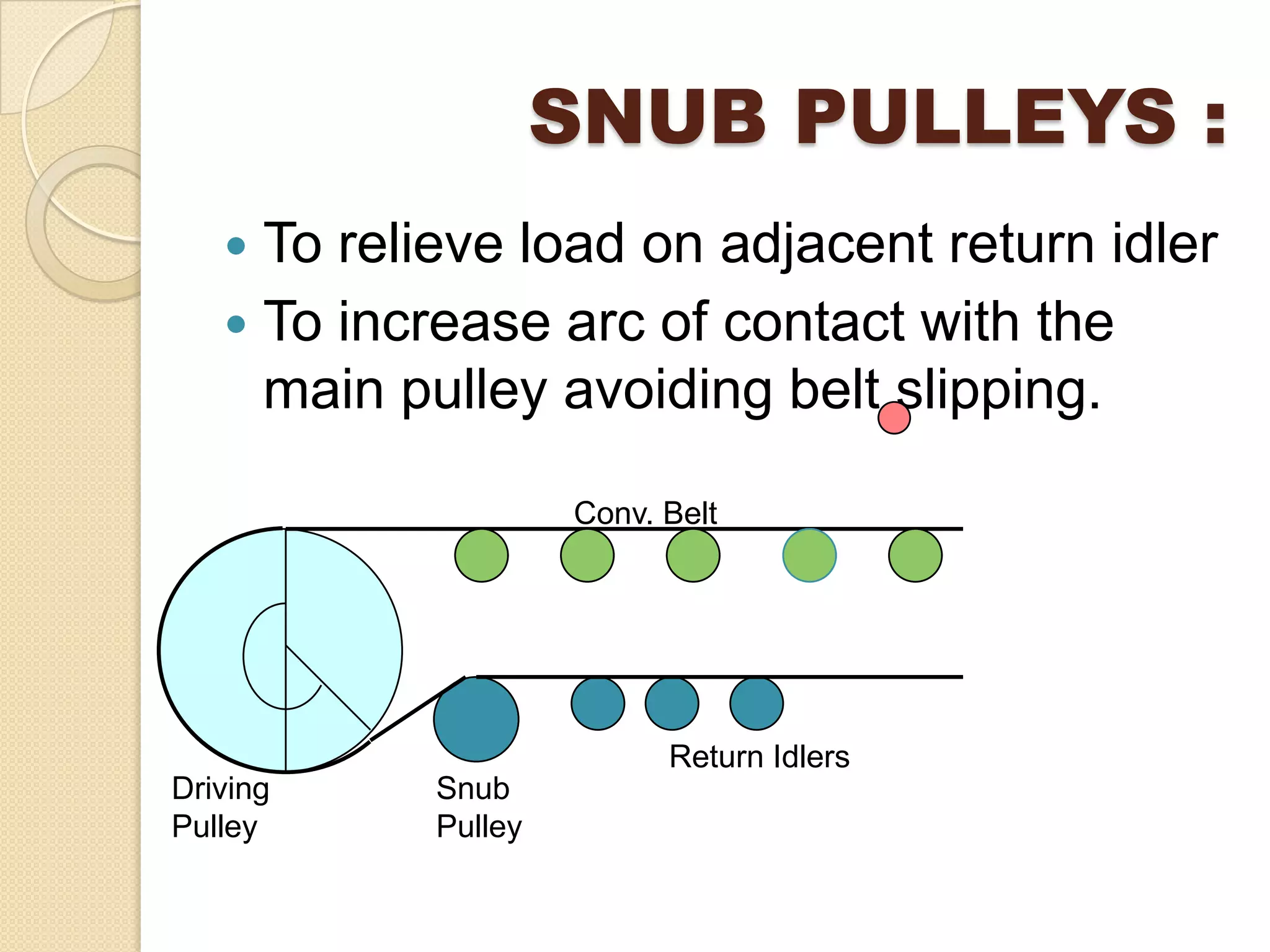

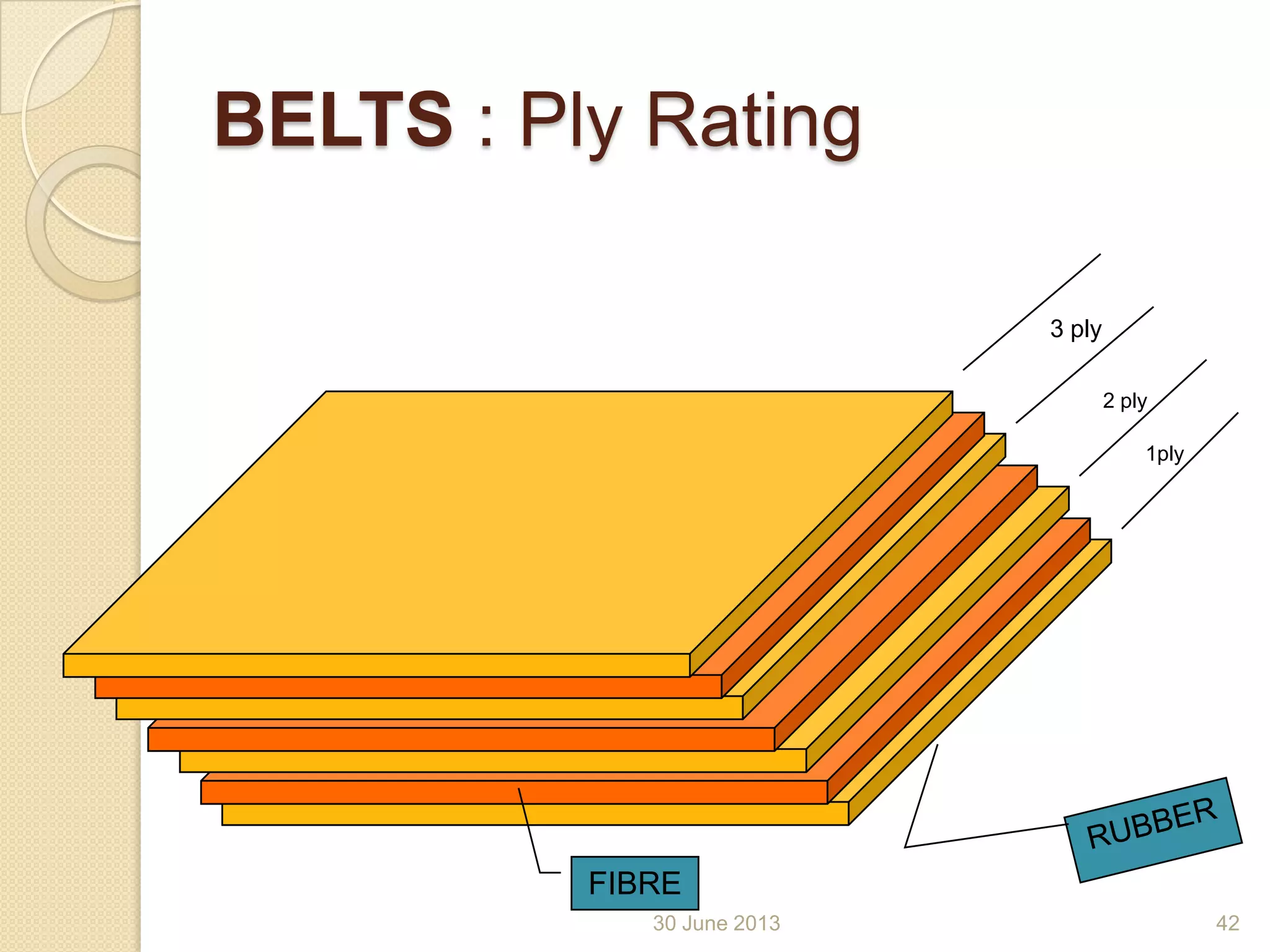

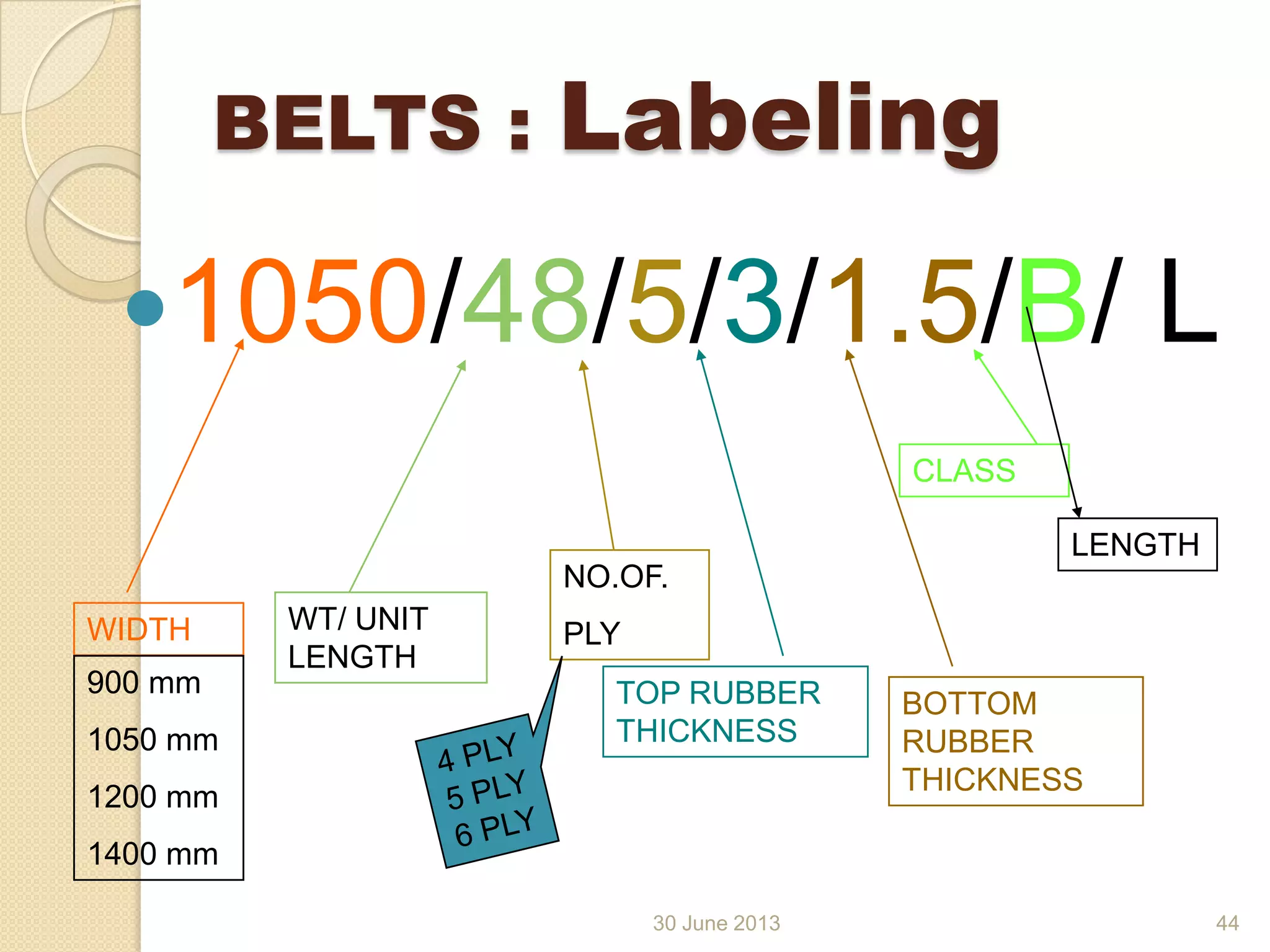

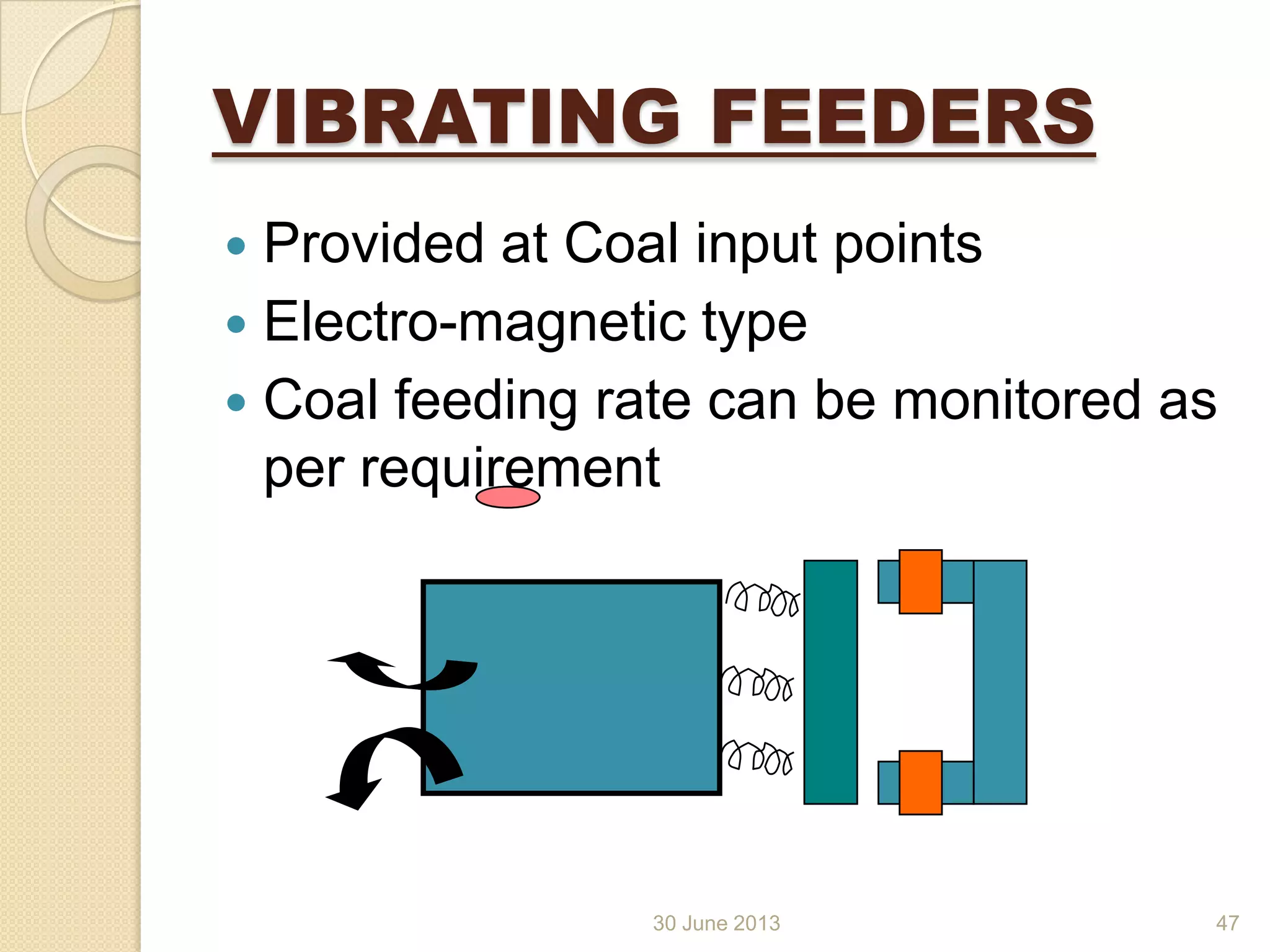

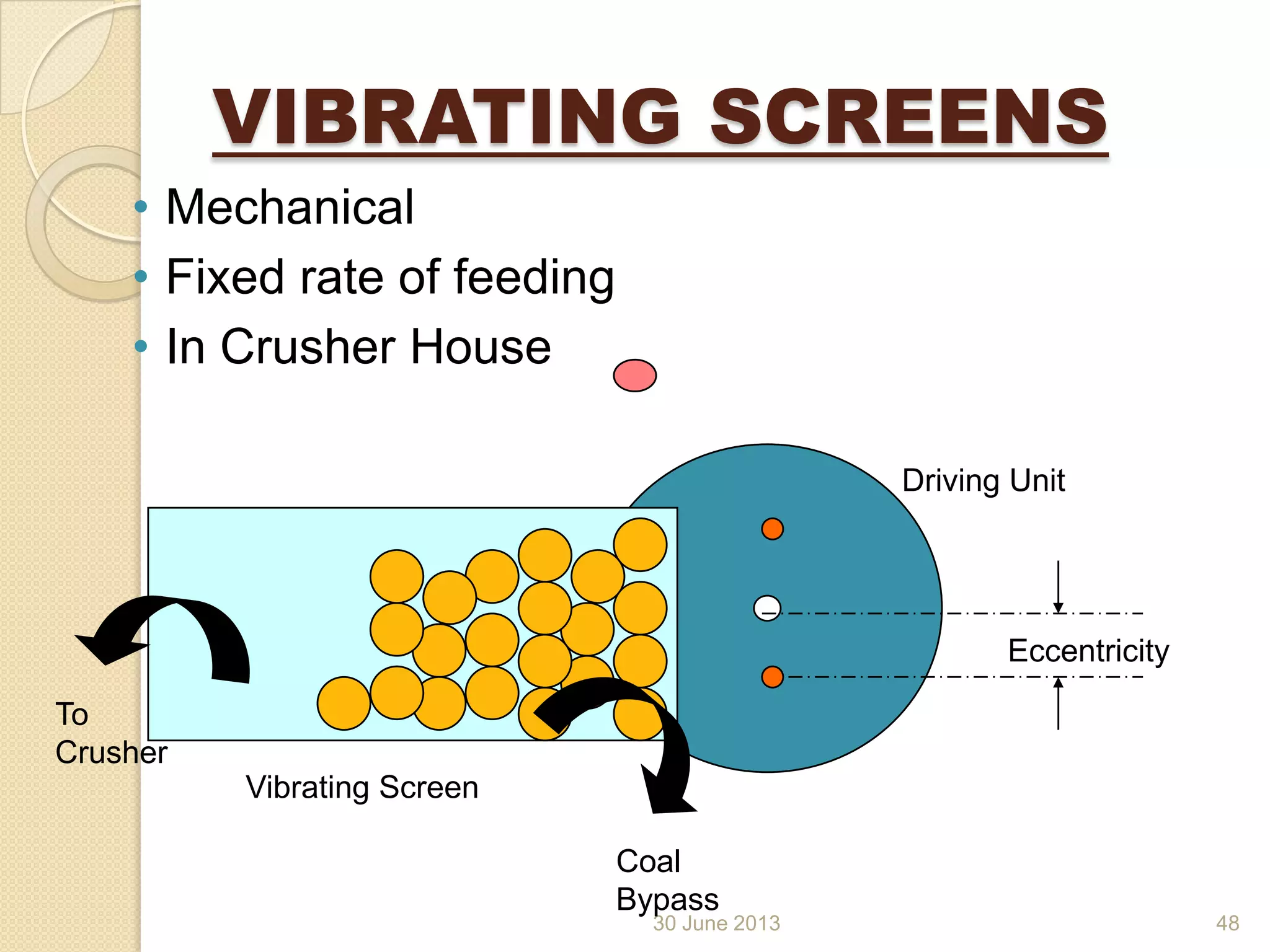

- Main components include wagon tipplers, crushers, conveyor belts, feeders, bunkers. Coal is crushed to different sizes and conveyed to bunkers or storage.

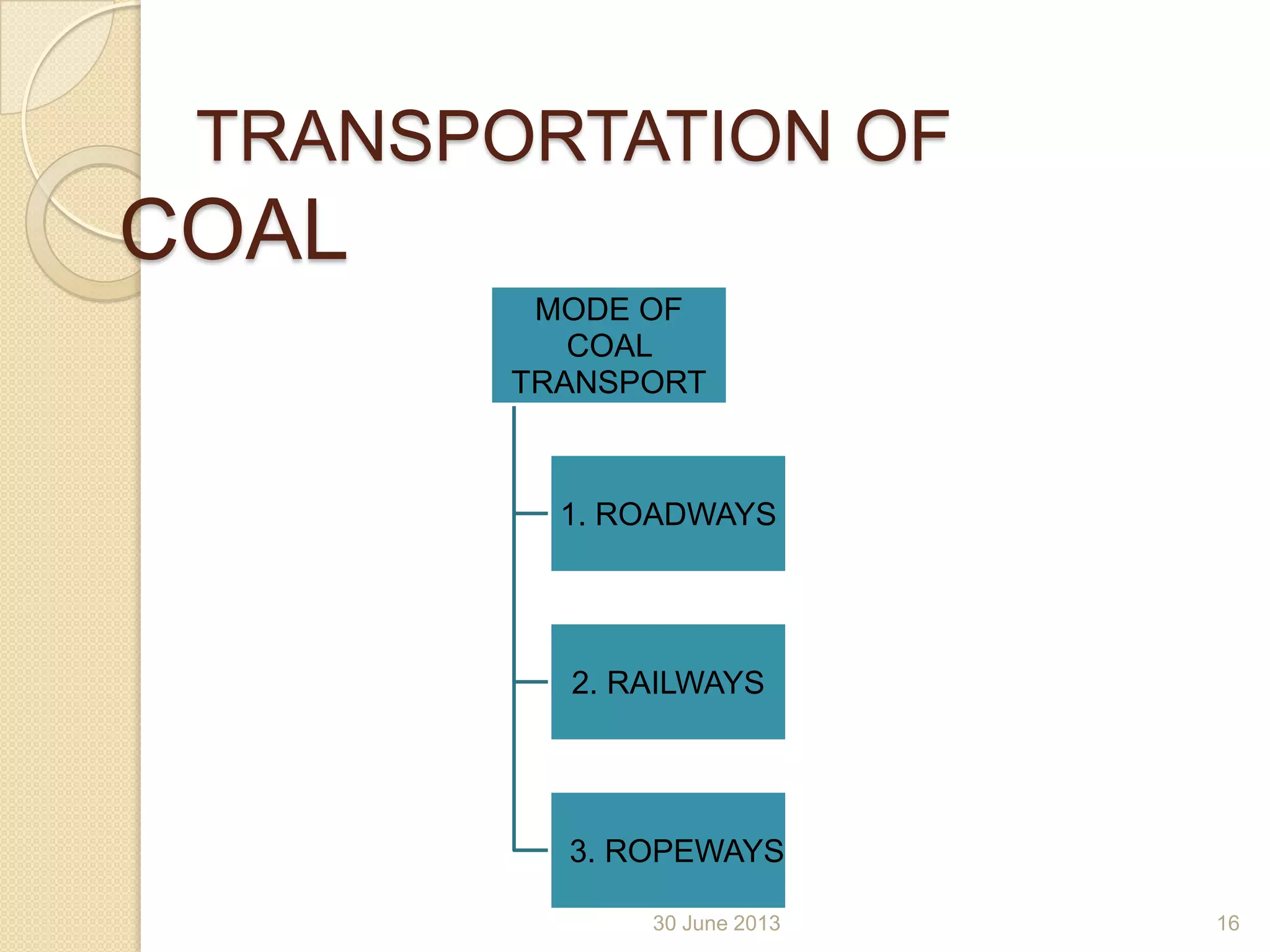

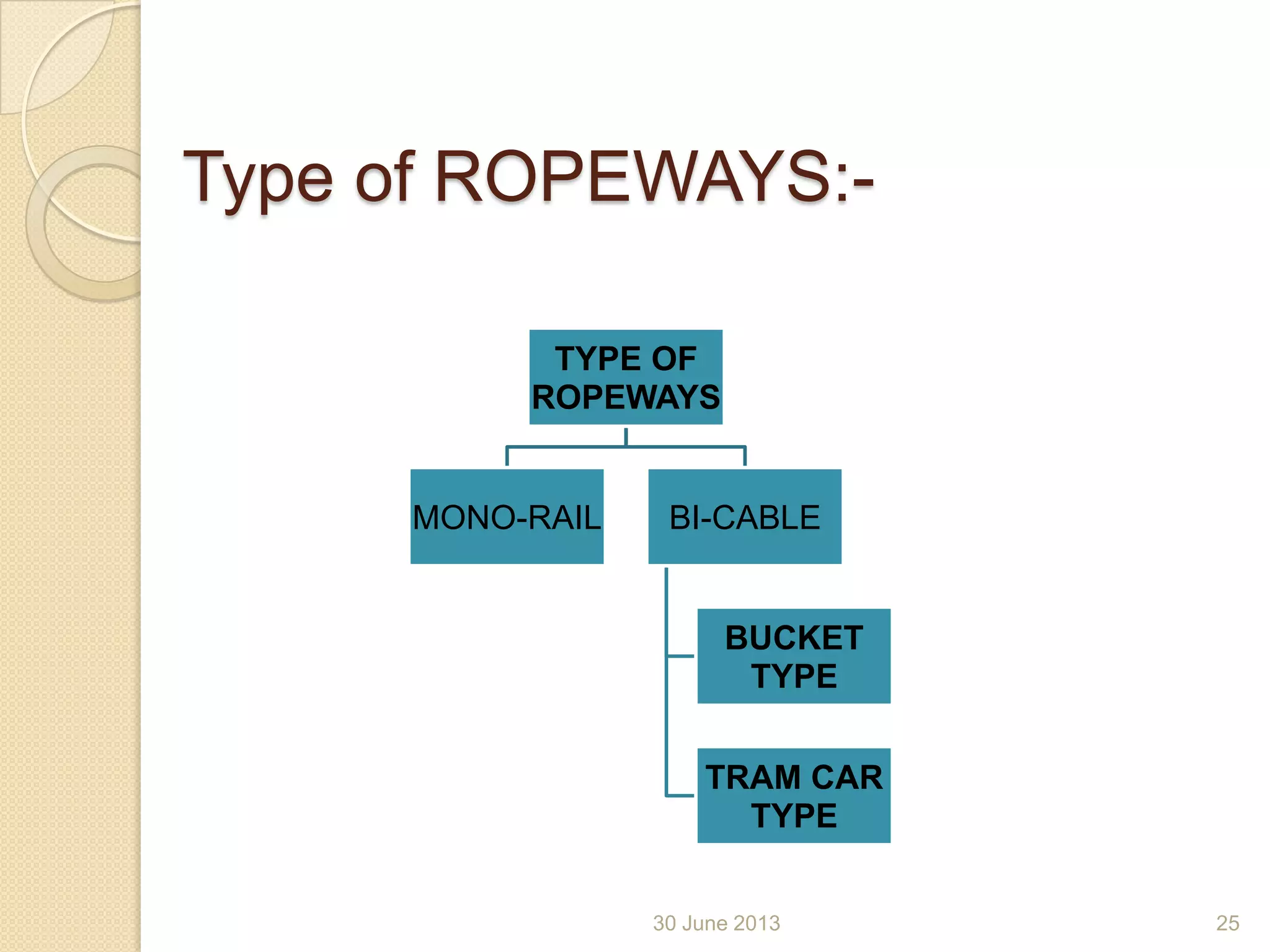

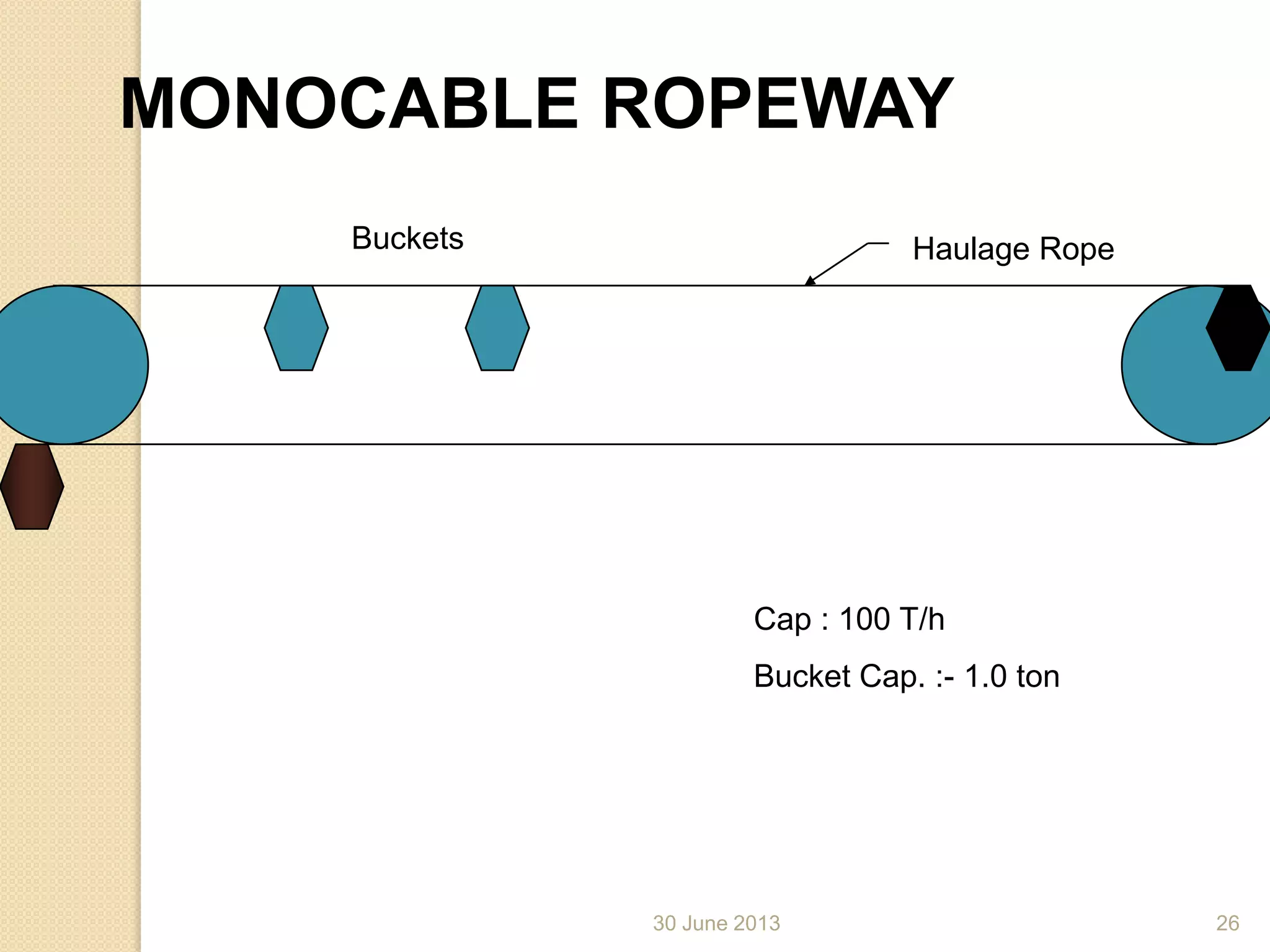

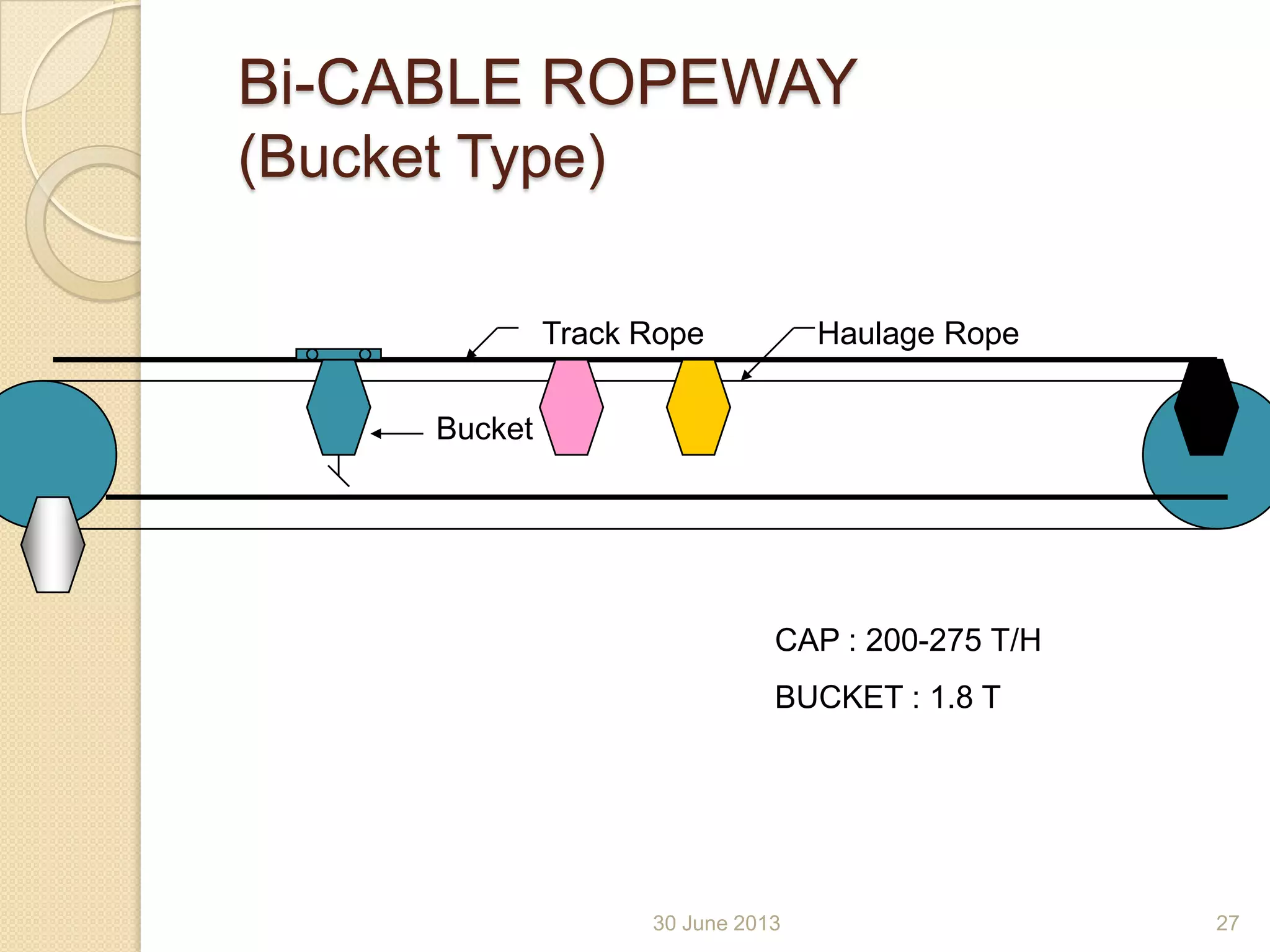

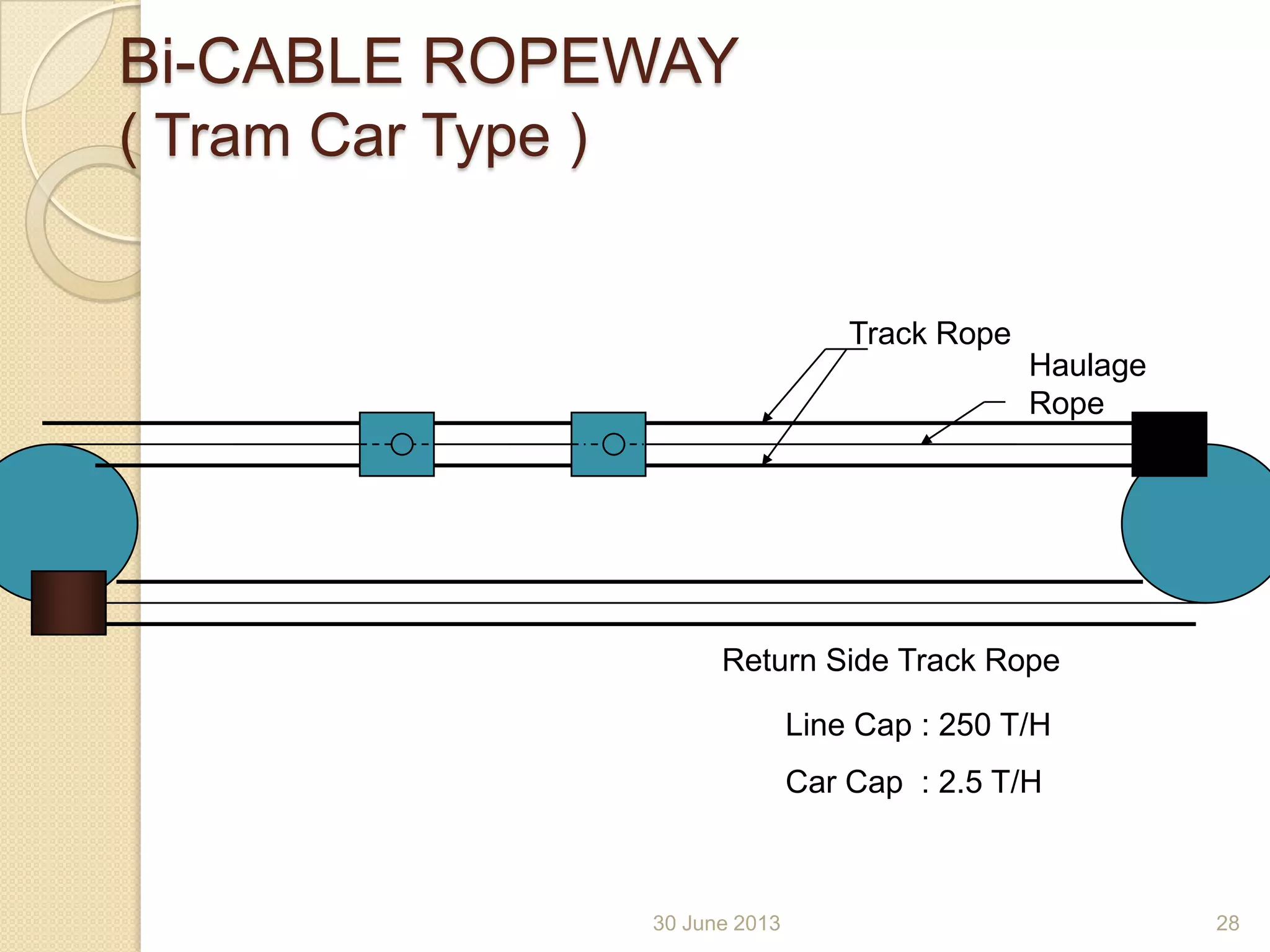

- Coal is transported mainly by railways in wagons and unloaded by rotary or side tipplers. Other transport modes include ropeways and road.

- The document outlines the operating sequence,