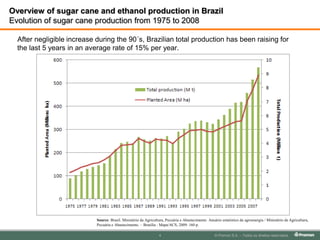

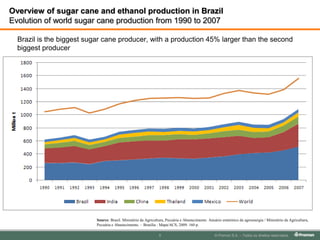

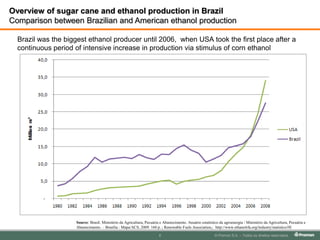

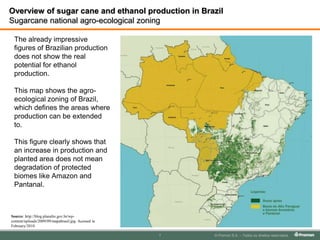

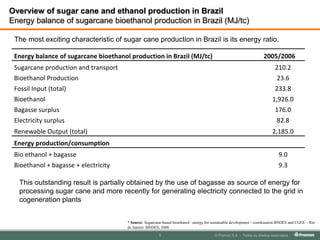

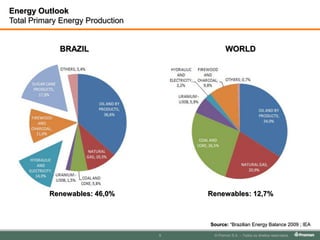

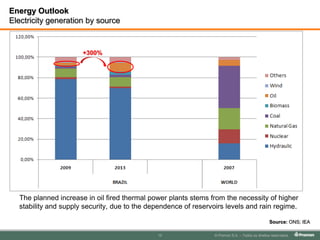

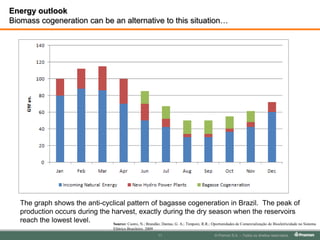

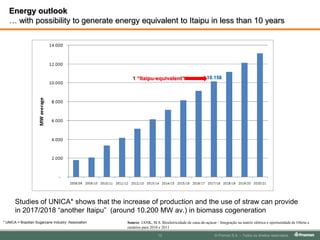

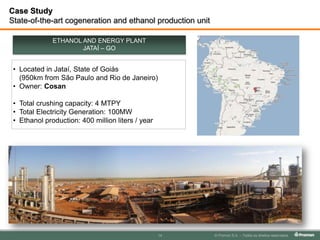

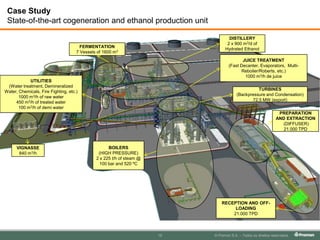

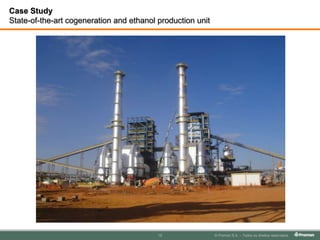

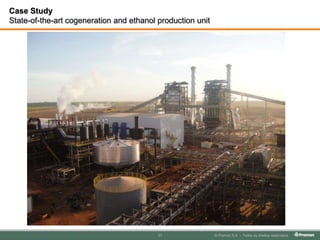

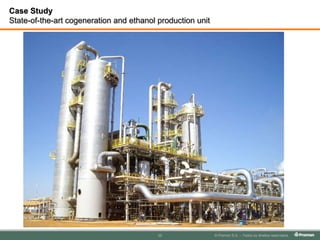

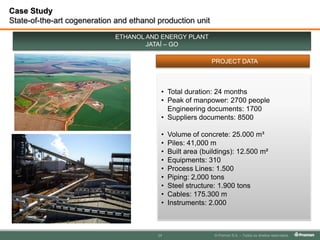

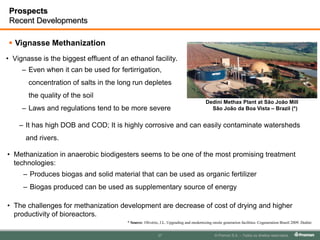

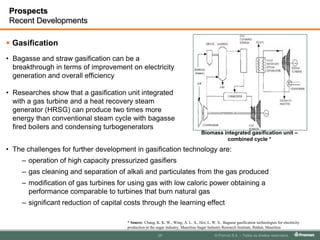

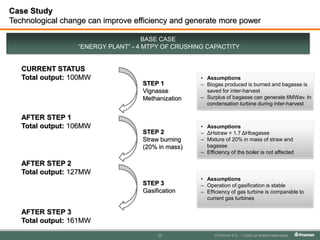

This document summarizes a presentation on sugar cane as an energy crop in Brazil. It provides an overview of sugar cane and ethanol production in Brazil, including trends over time that show Brazil is the largest producer. It also discusses Brazil's energy outlook, including the potential for biomass cogeneration from sugar cane bagasse and straw to generate electricity equivalent to a major hydroelectric dam. The presentation concludes by describing a case study of a state-of-the-art cogeneration plant and prospects for improving efficiency through utilizing straw, methanizing vinasse, and gasifying bagasse.