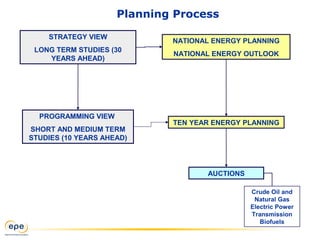

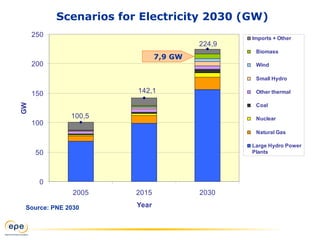

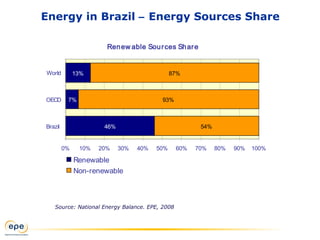

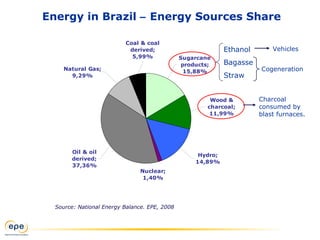

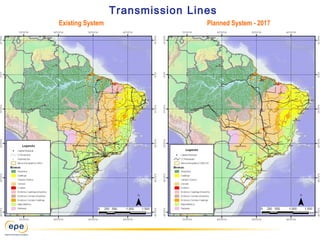

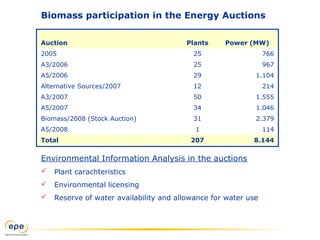

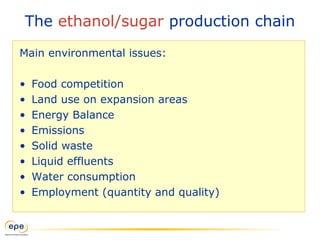

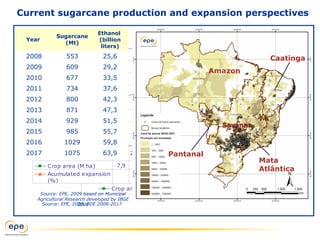

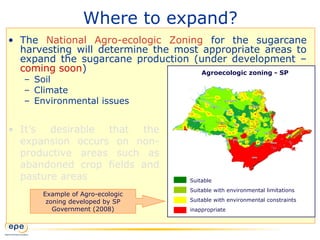

This document discusses environmental issues related to biomass energy generation in Brazil. It provides an overview of Brazil's energy sector planning agency EPE and the role of biomass, particularly sugarcane bagasse. The summary examines the main environmental impacts of sugarcane production including land use, emissions, waste, and water usage. It also notes that expansion areas will be determined by agroecological zoning and Brazil has significant potential for further development of bioenergy.