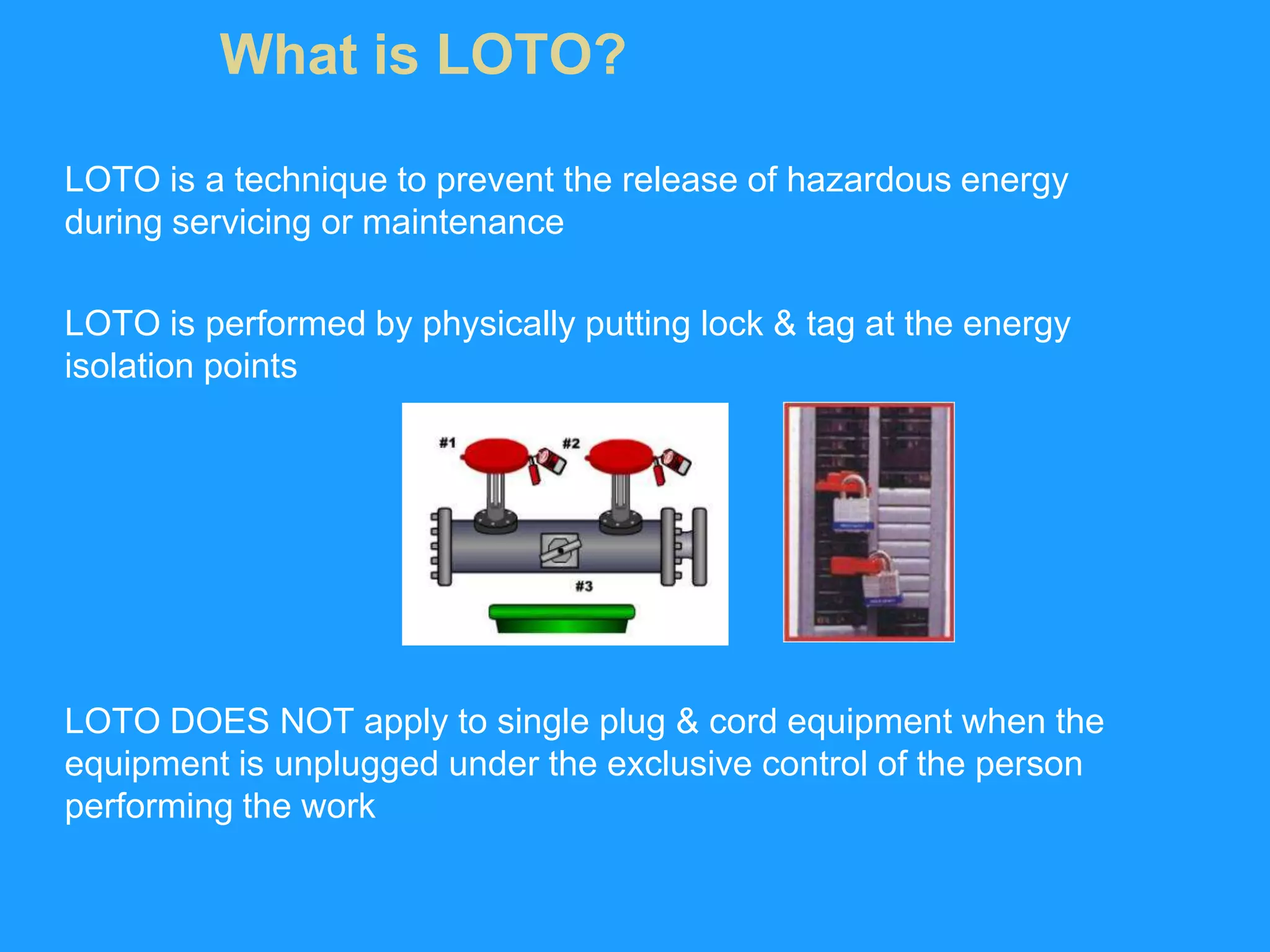

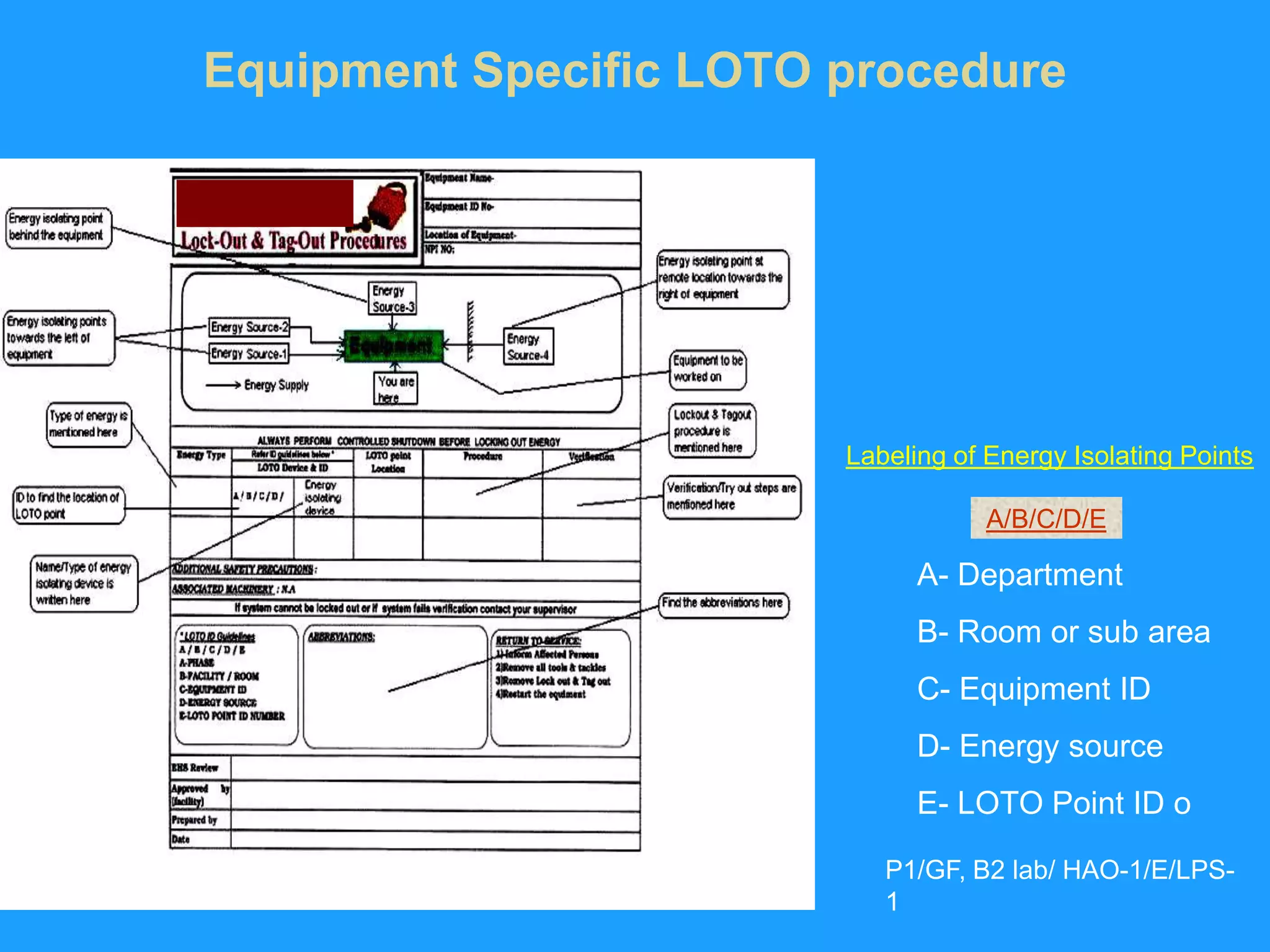

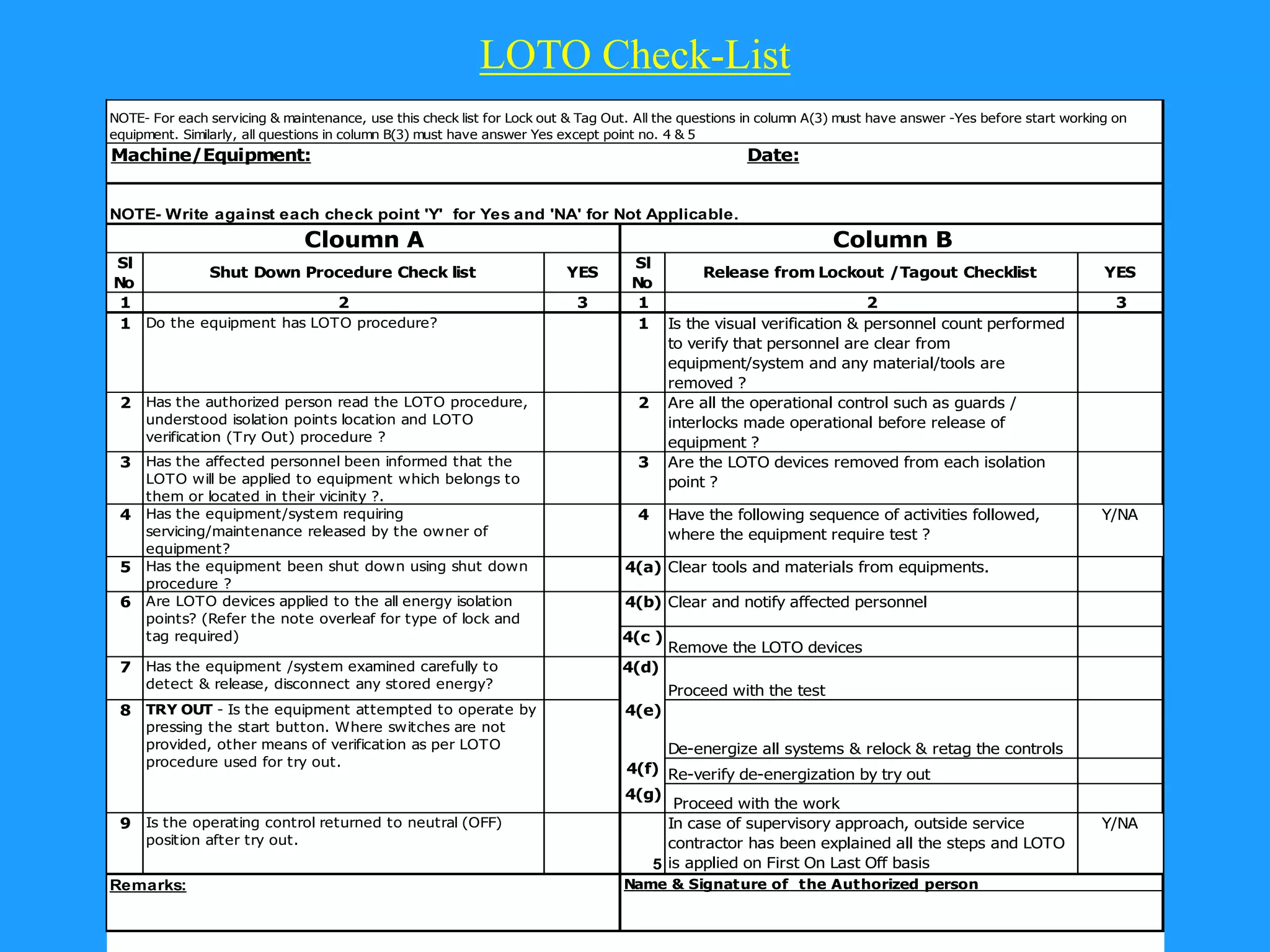

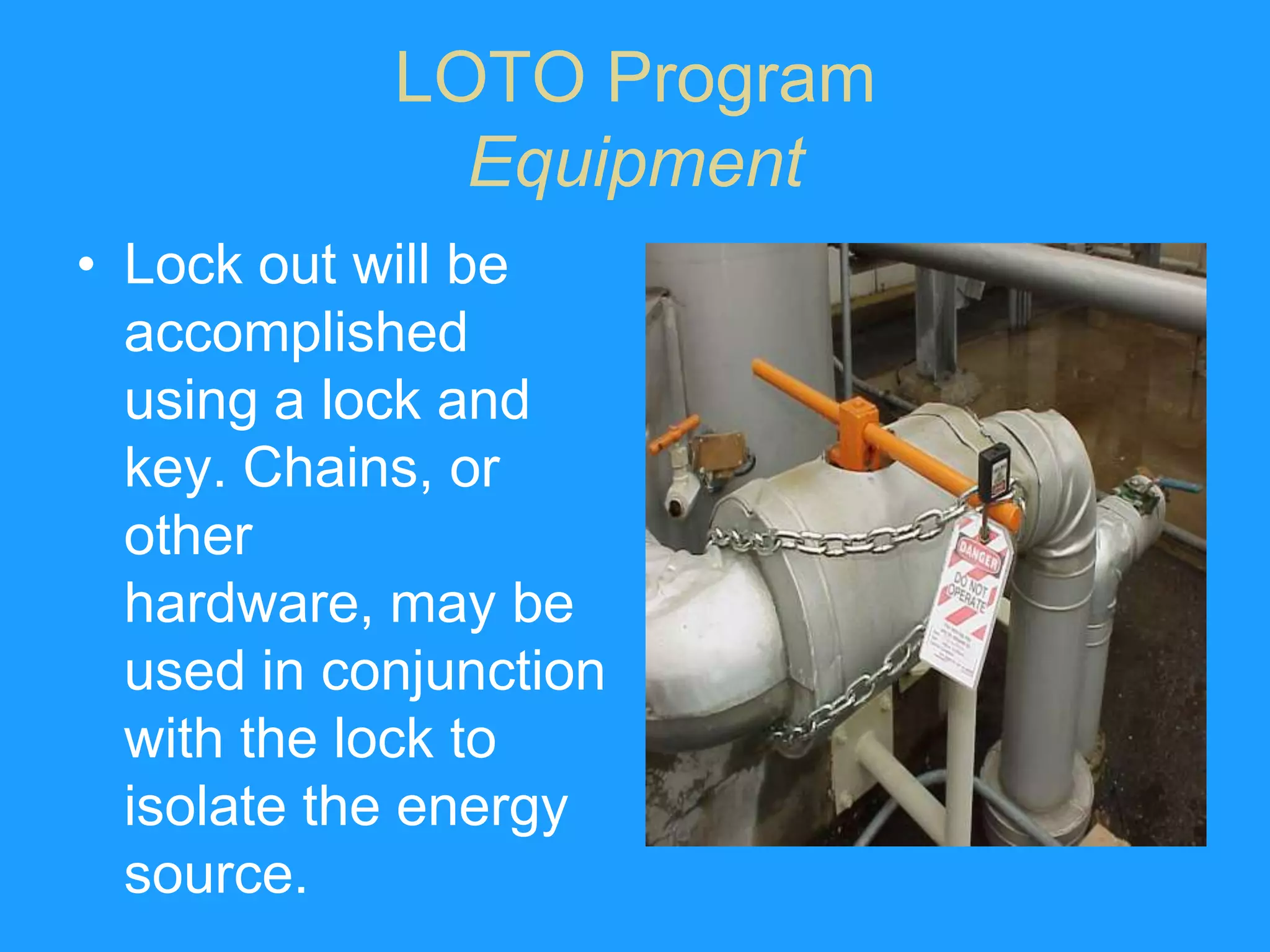

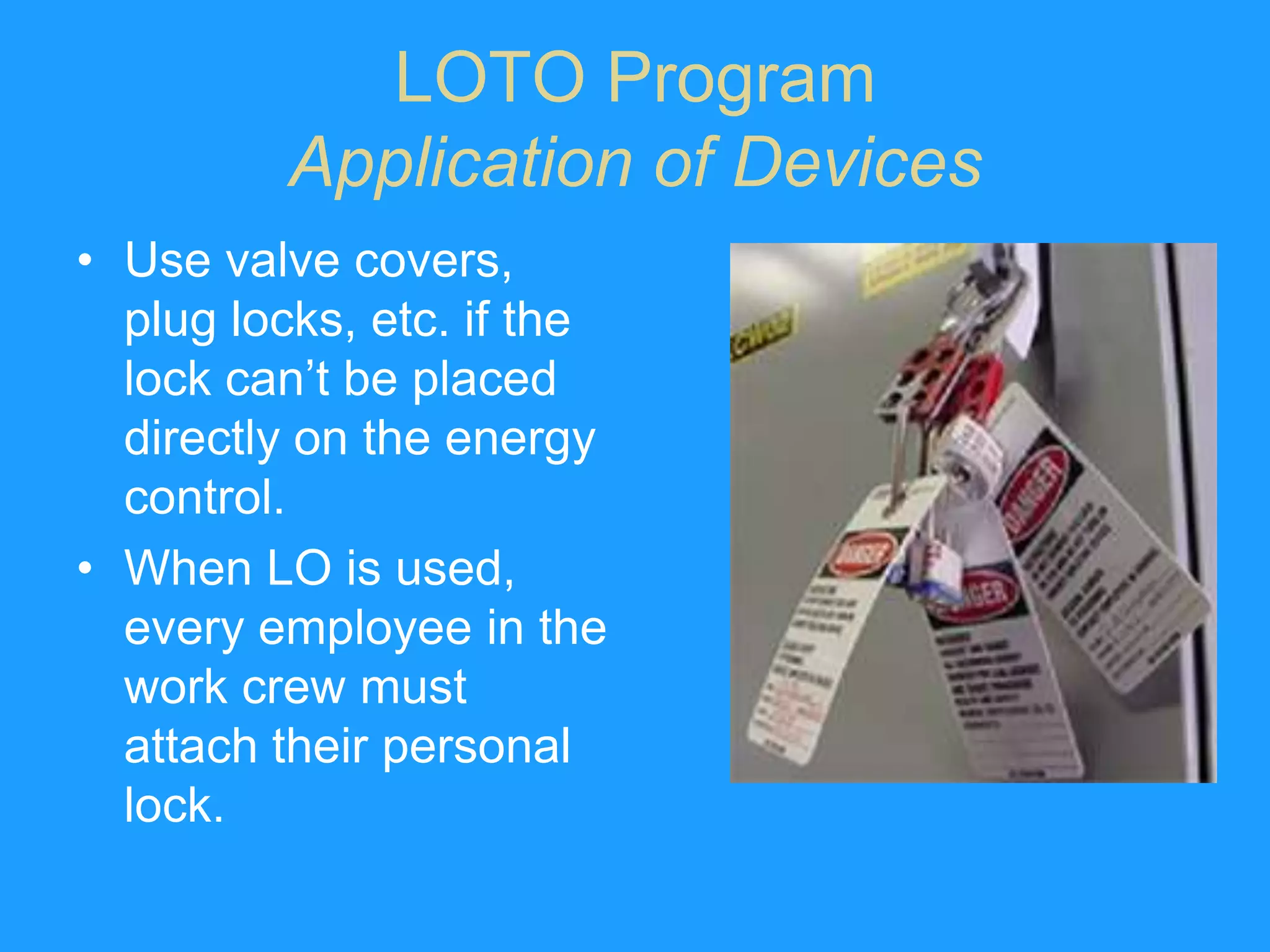

Lock Out Tag Out (LOTO) is an important safety procedure to prevent unexpected startup of machines and equipment during service or maintenance. It involves shutting down and isolating machines, applying personal lockout devices, releasing stored energy, and verifying isolation before work. The six key steps are: 1) prepare for shutdown, 2) shutdown equipment, 3) isolate energy sources, 4) apply locks and tags, 5) release stored energy, and 6) verify isolation. Proper LOTO training and compliance is needed to protect authorized and affected employees from hazardous energy during service and maintenance work.