This document summarizes the key points of OSHA's lockout/tagout standard including:

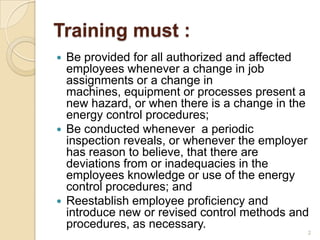

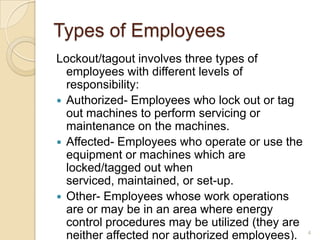

1) Employers must provide energy control procedure training for authorized, affected, and other employees. Training must be provided when job assignments change or energy control procedures change.

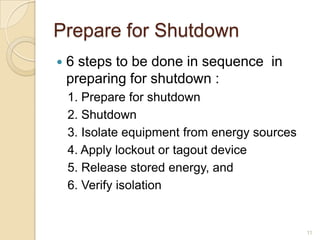

2) Lockout involves installing a lock on the energy isolating device to prevent the release of hazardous energy. Tagout involves attaching a warning tag to the energy isolating device.

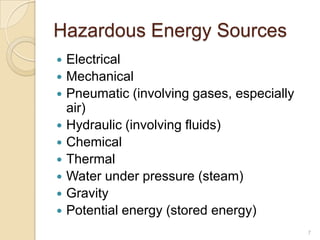

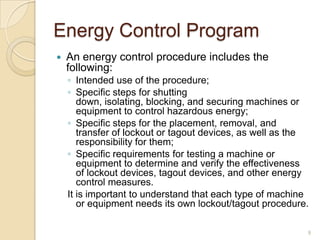

3) The energy control program consists of energy control procedures, training, and periodic inspections and must be used to isolate machines from hazardous energy sources before maintenance or servicing.