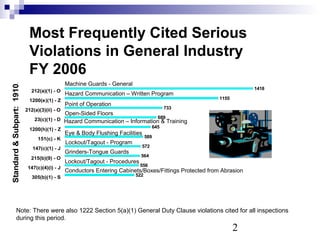

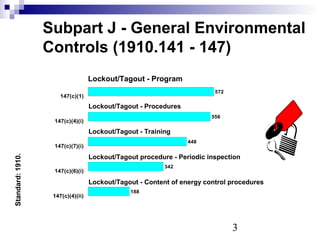

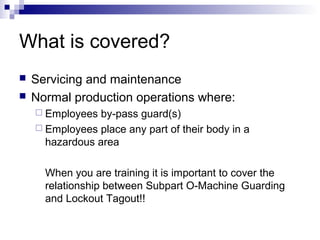

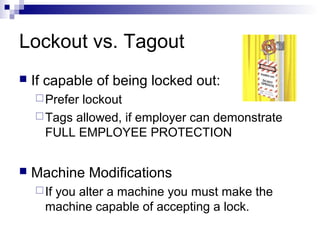

Lockout/tagout was the most frequently cited standard in 2006. It requires employers to have a written program including energy control procedures for each machine or piece of equipment. Employers must provide training to employees and periodically review the program. The standard aims to prevent injuries by ensuring that hazardous energy is isolated and controlled before employees perform service or maintenance on machines.