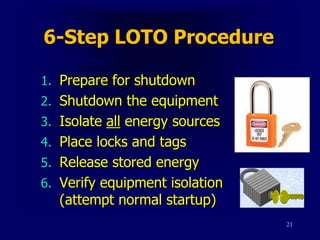

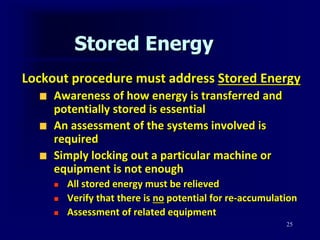

This document discusses lockout/tagout (LOTO) procedures for controlling hazardous energy sources. It covers the purpose of LOTO, which is to prevent injuries from unexpected equipment energization. Requirements include written procedures, training, locks/tags, and verifying isolation. Hazardous energy types are electrical, mechanical, chemical, thermal, hydraulic, and pneumatic. The 6-step LOTO procedure is outlined as preparing for shutdown, shutting down equipment, isolating energy sources, placing locks and tags, releasing stored energy, and verifying isolation. Stored energy must be assessed and relieved before work. Only authorized employees who have gone through training can perform LOTO procedures.

![Lockout / Tagout

(LOTO)

Control of

Hazardous

Energy

ADIS: P-6 [1-14]](https://image.slidesharecdn.com/p-61-14loto-35-2016-201202120006/85/LOTO-1-320.jpg)