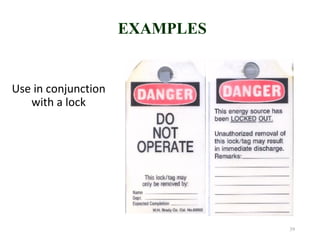

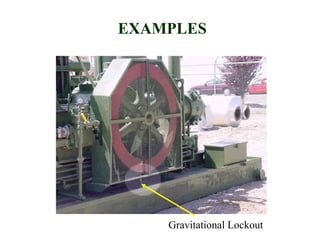

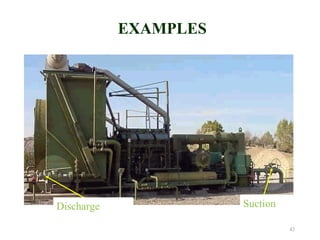

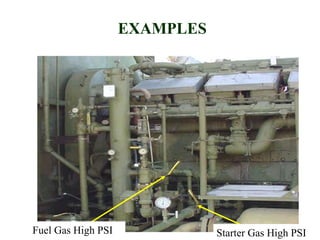

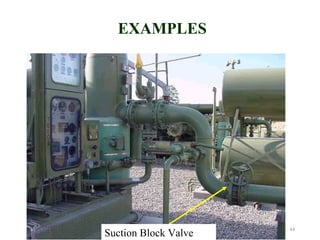

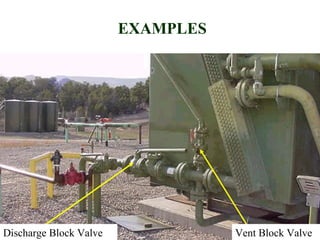

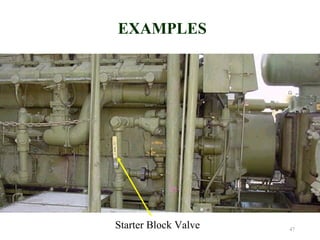

This document outlines requirements and procedures for lockout/tagout (LOTO), which protects employees from hazardous energy during servicing or maintenance of equipment. It defines key terms, outlines employer responsibilities to develop LOTO procedures and train authorized and affected employees. Procedures include shutting down equipment, isolating all energy sources, releasing stored energy, verifying isolation before work begins, and restoring equipment only after removing lockout/tagout devices. Examples of lockout/tagout devices for various types of equipment are also provided.